Laser-assisted machining of composites

Yung C. Shin

Processing polymer and metal matrix composites with improved machinability and minimized damage

In today’s engineering world, many classes of composite materials have emerged, including fiber-reinforced polymers (FRP), natural fiber composites, metal matrix composites (MMC), and ceramic matrix composites (CMC). Although these composites are generally processed to near-net shape, subsequent machining operations are inevitable for many engineering products. Among these materials, polymeric composites are one of the most popular, particularly in the aerospace industry that uses a large portion of carbon fiber-reinforced composites. Metal matrix composites, on the other hand, offer damage tolerance over a wider range of operating conditions. Popular reinforcement materials for these composites are silicon carbide and alumina; in particles and fibers aluminum, titanium, and magnesium constitute the most common matrix materials. Composite materials in general exhibit inhomogeneity, anisotropy, and non-ductile behavior. The inherent challenge in machining of these composites is the excessive tool wear and subsequent damage in the material sub-surface.

Machining of fiber-reinforced polymer matrix composites and particulate-reinforced metal matrix composites has been extensively explored in the past. These materials are shown to cause excessive tool wear, which in turn induces such damage phenomena as fiber pullout, particle fracture, delamination, and debonding at the fiber- or particle-matrix interface. Parameters that are the major contributors to the machinability of these composites are the reinforcement type and orientation, tool type and geometry, and the machining parameters.

Laser-assisted machining (LAM) offers a promising way of alleviating these problems. LAM is based on the idea of reducing cutting forces during machining by systematically lowering the material yield strength through the use of localized heating. LAM can achieve reduced tool wear, higher material removal rates, and better surface quality.

This article describes the capabilities of laser-assisted machining for long-fiber and particulate-reinforced metal matrix composites from the standpoint of improving machinability, reducing tool wear, and minimizing sub-surface damage such as delamination or debonding. To demonstrate the benefits of LAM, two case studies are described.

Long fiber-reinforced composites

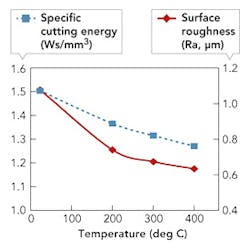

The material used for the first case study is an alumina fiber-reinforced aluminum matrix composite, which contains 60% by volume fraction alpha-alumina long fibers and Al-2%Cu as the matrix material. FIGURE 1 shows the variation of specific cutting energy and surface roughness as a function of Tmr (material temperature just prior to cutting due to laser heating). Both surface roughness and specific cutting energy decreased by up to 70% when LAM was applied at Tmr of 400°C. In case of Tmr of 300°C, there was a 65% reduction in the surface roughness and specific cutting energy as compared to conventional machining. A Tmr of 300°C yielded less damage and the lowest ratio of thrust force to cutting force, indicating this is the most effective material removal temperature.

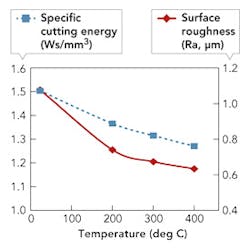

FIGURE 2 shows the parts produced by conventional machining and LAM. Compared to conventional machining, LAM produces a smoother surface and no burr was formed.

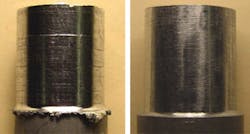

Tool wear rate also improved with laser heating. In this particular case, tool wear was characterized by flank wear and subsequent catastrophic failure of the cutting edge by attrition or chipping. FIGURE 3 plots the measured wear rates as a function of Tmr. LAM significantly reduced the tool wear rate by approximately 38%, 65%, and 66% respectively over conventional machining at Tmr of 200°C, 300°C, and 400°C.

Damage in the composite is characterized in this case through excessive fiber breakage below the cutting plane. Scanning electron microscopy (SEM) images obtained from the interior cross-section of the workpieces revealed that the average measured values for the debonding/fiber damage are 157 µm, 149 µm, 125 µm, and 122 µm for the workpieces machined at Tmr of 23°C, 200°C, 300°C, and 400°C respectively. It is clear that observable damage in terms of fiber pullout decreased with increasing material removal temperature. The damage in the composite decreased with decreasing thrust force.

In summary, LAM significantly reduced the specific cutting energy, surface roughness, tool wear, and fiber pullout as compared to conventional machining. A Tmr of 300°C LAM provided a 65% reduction (threefold improvement) in surface roughness, specific cutting energy, and tool wear rate over conventional machining under identical cutting conditions.

Particulate reinforced composites

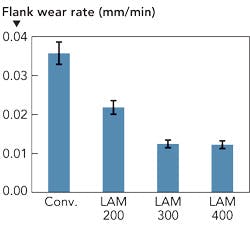

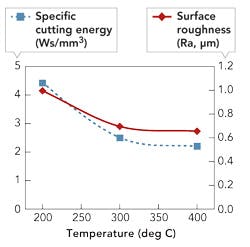

The second case study of LAM is an application to particulate-reinforced composite: A359 aluminum matrix composite reinforced with 20% by volume fraction silicon carbide particles. FIGURE 4 shows the variation of specific cutting energy and surface roughness as a function of Tmr. Surface roughness and specific cutting energy decreased by approximately 40% and 15% respectively when LAM was applied at Tmr of 400°C. In case of Tmr of 300°C, there was a 37% reduction in the surface roughness and a 12% reduction in the specific cutting energy.

Surface roughness was used as a metric for identifying the effective tool life due to the rapid deterioration of surface roughness to an unacceptable level, although flank wear is typically used as the measure of tool wear in conventional materials. Table 1 summarizes the amounts of material removed when the surface roughness value reached 2 μm. Based on this criterion, it can be concluded that LAM outperforms conventional machining by approximately 2.2-2.35× at cutting speeds of 50-100 m/min. In the cutting speed range of 150-200 m/min the improvement by LAM was approximately 1.7× conventional machining. These results demonstrate a considerable improvement in machinability by LAM over conventional machining with a carbide tool.

LAM tool wear tests were conducted using a polycrystalline diamond (PCD) tool at the nominal cutting condition of 150 m/min and Tmr of 300°C also. As expected, PCD tools outperformed their carbide counterparts. Additionally, it was observed that LAM once again consistently showed lower tool wear compared with conventional machining. Using PCD tooling in combination with LAM reduced the tool wear by as much 6× as opposed to 4.4× with conventional machining for the limited amount of material removed. Similar to conventional machining, cutting forces observed while machining with PCD tooling are much lower compared with machining with carbide tooling. This could once again possibly indicate lower sub-surface damage.

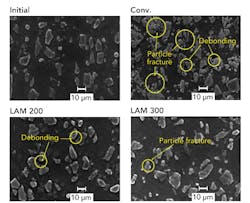

LAM can also reduce the subsurface damage as a result of reduced cutting force. To inspect damage after machining, SEM images were obtained from the interior cross-sections of the workpieces before and after machining at different conditions. FIGURE 5 shows the cross-sections of the original and machined parts at the feed rate of 0.1 mm/rev, cutting speed of 150 m/min, and depth of cut of 0.76 mm and Tmr of 200°C, 300°C, and 400°C, respectively. The initial sample is relatively damage-free with only a few pores observable in the matrix. The images of machined parts indicate the extent of debonding between the particles and the matrix along with particle fracture. The sub-surface damage of the composite for Tmr of 200°C, 300°C, and 400°C remained fairly constant. The results indicate that the damage depth with LAM is relatively independent of Tmr. On the other hand, conventional machining resulted in excessive particle fracture, which is very prominent as shown in FIGURE 5, while it was nearly absent in the parts produced by LAM. For all cutting conditions, the sub-surface damage was measured after machining 20 mm (length of cut) with fresh cutting tools. At a cutting speed of 150 m/min the average sub-surface damage depth was 68±14 μm, 45±6 μm, 38±6 μm, and 38±4 μm for Tmr of 23°C, 200°C, 300°C, and 400°C respectively.

Cutting Speed | Conventional: Volume of Material Removed (cm3) | LAM: Volume of Material Removed (cm3) | Times Improvement |

50 m/min | 6.48 | 15.26 | 2.35× |

100 m/min | 7.00 | 15.38 | 2.20× |

150 m/min | 12.08 | 21.13 | 1.74× |

200 m/min | 11.45 | 19.2 | 1.68× |

Tool wear in terms of material removed for a surface roughness value of 2 μm.

In summary, LAM significantly reduced the specific cutting energy, surface roughness, tool wear, and sub-surface damage as compared to conventional machining. At Tmr of 300°C, LAM yielded a 37% reduction in the surface roughness and a 12% reduction in the specific cutting energy over conventional machining using the identical cutting conditions. LAM also produced a 1.7–2.35× improvement in tool life over conventional machining dependent on the cutting speed. Tests with PCD tools showed that machining with a PCD tool results in reduced tool wear of approximately 4–6× over carbide tooling, for conventional machining and LAM respectively, at a cutting speed of 150 m/min. For machining of these composites, PCD tooling in conjunction with LAM is recommended. LAM offers similar benefits for machining of polymeric and ceramic matrix composites. ✺

Dr. Yung C. Shin is the Donald A. & Nancy G. Roach Professor of Advanced Manufacturing at the School of Mechanical Engineering, Purdue University, West Lafayette, IN.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles