Blackhawk definitely not down

Salem, OH–Trimming vacuum–formed appliques for the auto industry using metal trim dies has been updated by the March 2002 addition of a laser trimming system. Blackhawk Automotive Plastics chose a robotic–based trimming system from Robotic Production Technology (RPT–Auburn Hills, MI) for the following reasons.

The system provides increased flex ibility to handle part changes and the trim path can be quickly modified. Improved applique edge quality reduces scrap in the molding process and labor used to trim edges prior to molding. The die method was a single–cavity process requiring la bor to preprocess for the four–cavity vacuum–formed mold. The robotic system, with its arm–mounted Rofin Sinar (Plymouth,MI) 200–watt CO2 laser, handles the multiple–cavities part without preprocess labor.

For more information, contact RPT at Tel. (248) 829–2800 or visit www.rpt.net.

Need an applications expert?

Kanata, ON & Wilmington, MA–Users interested in laser pro cessing can now submit their questions to GSI Lu monics via e–mail. Within two business days, you should get an answer. The service, called "Ask an Applications Ex pert," is accessed from the company's Website www.gsilu monics. com by click ing on "Cutting, Drilling & Welding."

A second GSI Lumonics service, "Get Samples Processed," is also ac cessed from the same site. Here an inquirer fills–in a form with application details and the company will contact them to arrange for sample processing.

Auto–related activity hot at Trumpf

Plymouth, MI–Trumpf Inc. continues to book orders from the auto industry even when this industry seems to be in a bit of a slowdown, at least as far as buying lasers goes. Sources tell ILS that Trumpf remains strong in the hydroforming market with more than 240 CO2 and Nd:YAG laser installations through the end of last year. Also, a new player in the airbag manufacturing sector has set–up a new operation in Mexico using Nd:YAG lasers for welding. In addition, Harley Davidson uses various Trumpf laser–welding technologies at several of its North American facilities.

This year the company will install a body–in–white roof welding system at a Midwest location. Moreover, Daimler Chrysler (Kokomo, IN) broke ground for a new powertrain facility using high–power CO2 lasers to manufacture a Mercedes transmission. –DAB

Laser welded bellows available

Orlando, FL–High–quality laser welded "soft" metal bellows are now available from LaserTech USA. The mechanical resistance to the axial motion of the bellows (spring rate) is reduced compared to conventional bellows of the same size.

This product, called Laserbellows, is suit able for hermetic sealing for ultra–high vacuum and other applications. These bellows last five times longer than the designed one million cycles.

Standard sizes from one to four inches OD are available within two to eight weeks; other sizes take 10–14 weeks for delivery. Contact the company at Tel. (407) 438–9015 or access its Website at www.lasertechllc.com.

GSI Lumonics hits paydirt

Northville, MI–Freely admitting that 2001 was a challenging year for its Precision Manufacturing Group, GSI Lumonics focused on the support of critical installations around the world and the development of new products for an aggressive 2002 launch.

Last March the company began delivering what it believes is the largest deployment of CW Nd:YAG laser cutters at a multiple–site project, manufacturing subsystems for the auto industry. This 56–laser project will have all units up and running by summer, with all performance targets being achieved. –DAB

Jeweler replaces soldering with laser welding

Ventura, CA–Van Gundy & Sons Jewelers, a 40–year–old family–owned enterprise, now offers state–of–the–art laser welding to provide a 260–percent stronger, permanent connection that assures safety and accuracy when bonding jewelry.

The Laserstar system, which provides low thermal input that protects fine stones, is a versatile tool for repairing and restoring non–repairable jewelry, instead of the traditional method–torch soldering. The laser can be used on costume and vintage jewelry such as rhinestones, watchbands and filigree jewelry.

Van Gundy is the area's largest manu facturing jeweler, now even stronger because of the laser, which enables the repair of even the most damaged and delicate jewelry. Access the company Website, www.van gundys. com, for more information. –Internet Wire Inc.

Caterpillar plans to aid UK community

East Cleveland, UK–According to the publication Newsquest (The North East) Ltd, Caterpillar has plans to add new equipment, including a laser cutter, to its Skinningrove facility. Local government entities applauded the news saying the new project will create high–skill–level jobs essential to the future success of the North East.

Caterpillar already employs 1100 people here, so the planned addition of 42 workers, while not earth shattering, is reinforcement of the company's commitment to the local economy. The products that the laser–cut parts will encompass are the track shoes that the Cat tracks run on. These will be exported worldwide.

Grant will lead to laser cutter purchase

Sunderland, UK–Auto part manufacturer Magna Kansei will use a Department of Trade and Industry grant of £850,000 to purchase vacuum forming and laser cutting equipment. A company official said the grant, along with other company investment, would encourage new skills and create new opportunities in the region. The jobs being created are in engineering, logistics and manufacturing.

The company supplies parts to Nissan, BMW, Land Rover, General Motors and Jaguar. According to a company source, the company will assemble plastic modules, ready–made to fit into a vehicle body. With the investment, the company expects to double sales revenues by 2004. –Newsquest

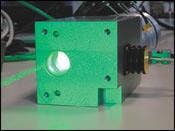

Green laser for marking

Pawtucket, RI–Last year ILS reported on the introduction of frequency–shifted solid–state lasers for marking applications at trade shows in Europe. One of those units is now available in the U.S. from Laservall North America LLC.

The Violino Green, a Q–switched (up to 200 kHz) frequency–doubled, air–cooled, di ode– pumped Nd:YAG laser can be used as the power source in OEM marking systems. Producing up to 8 watts at 532 nm, from a compact package, this unit is ideal for system integration.

An optional marker package includes a scanning head, DSP control card, marking software and flat field focal objective.

For more information, call the company at (410) 724–0076 or visit www.laservall–usa.com. –DAB

Ford laser–cuts the Expedition

Elizabethtown, KY–Among the many changes in the 2003 Ford Expedition/ Navigator is a chassis that is 70 percent stiffer than previous models, providing a solid foundation for exceptional on–road capability. According to the company, the new frame isolates road vibrations for a more com fortable ride.

Laser–cut right– and left–hand center siderails are assembled into the full frame here at Dana Corporation's Structural Solu tions Division. Eight 1kW Nd:YAG lasers sup plied by Trumpf (Plymouth, MI) are utilized to cut through–holes into hydroformed siderails. These holes are required for frame and vehicle assembly.

Dana commissioned the installation in March last year. The lasers, which incorporate Precitec Inc. (New Hudson, MI) cutting heads and ABB (Fort Collins, CO) robots, were integrated by Prodomax Industrial Automa tion (Barrie, Ont). –DAB

Leibinger prize to be awarded again

Ditzingen, Germany–Two years after its introduction, the prestigious Berthold Leibin ger Innovationspreis for applied laser physics will be awarded. This time the theme of laser medicine will be added to the original theme–lasers in production technology.

The primary aim of the award is to encourage research and development and the transferring of this technology to the public. Total prize money of 35,000 Euros is offered, in addition to the honor of receiving this award.

Interested applicants can contact Sven Ed er er at innovatinspreis@ leibinger–stif tung. de or access the Web site www.leib inger–stif tung.de. The application deadline is March 31, 2002.

Cutting small–diameter tubing

San Clemente, CA–According to Shane Cook, marketing manager, business at Stent–Cil Inc. is strong, necessitating the addition of engineering personnel to keep up with the demand. The five–year–old manufacturer of Nd:YAG laser cutters used for fine cutting of small tubing also de velops precision laser systems for machin ing, drilling and welding. The company also supplies glovebox laser systems for environmentally controlled ap plications.

Contact the company at Tel. (949) 361–0321 or visit the company website at www. stentcilinc.com.

Correction

Captions for the February feature Laser Welding Photonic Devices were wrong. They should have been:

Figure 1. Butterfly package with two beam laser welded ferrules.

Figure 2. Pulsed Nd:YAG laser welders for photonic devices.

Figure 3. Pigtailing with laser welded ferrule and clip.

We regret any confusion this has caused.