"Any color you like . . ."

By Larry Marshall

Everything you always wanted to know about frequency shifting

Recent developments in diode–pumped solid–state (DPSS) laser and nonlinear materials are driving major changes in laser materials processing. DPSS lasers have decreased the size, increased the electrical efficiency and improved the beam quality of solid–state lasers by reducing waste heat and allowing controlled distribution of gain within the laser crystal. Improved beam quality results in smaller, more stable focal spots that produce higher peak powers, which facilitate stronger laser/material interactions. This increase in laser "brightness" both improves material processing and increases the efficiency of nonlinear wavelength conversion. In conjunction with DPSS lasers, nonlinear materials now provide long–lived sources of visible and ultraviolet (UV) radiation through frequency doubling and tripling, shifting laser energy from the infrared (IR) into the visible or UV.

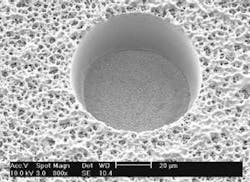

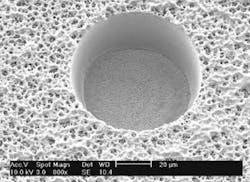

The combination of a diffraction–limited beam and short–wavelength laser enables machining of extremely small feature sizes, as focal spot size is proportional to wavelength and beam quality. Figure 1 shows a 75µm via–hole drilled by a 355nm DPSS laser. Furthermore, many materials that are reflective or transparent to IR lasers, such as copper or silicon, respectively, can interact efficiently if the laser is frequency doubled into the green. Nonlinear conversion can be merely enhancing or literally enabling of a process. For example, a 355nm photon has three times the energy of a 1064nm photon. This enables the UV photon to break molecular bonds that the IR photon would simply not affect. While DPSS lasers have improved the capabilities of existing solid–state lasers and existing processes, nonlinear optics will extend those capabilities to entirely new material processing interactions.

Diode–pumped solid–state lasers

Diode–pumped lasers can produce far shorter Q–switched pulses than their lamp–pumped counterparts, offering increased peak power. A typical 50W industrial lamp–pumped YAG (LP YAG) laser produces 200ns Q–switched pulses. A low–cost DPSS laser produces only 5 W, but in 10ns pulses. The peak power of DPSS lasers is two times greater, even with only 1/10th the average power. Furthermore, even a single–mode 50W LP YAG is actually multimode with a typical beam quality of M2 ~ 2, which significantly degrades the focus. To illustrate, if a given optical system gives a focused spot diameter of j from a beam with M2 = 1, then another beam with M2 = 2 will give a focus diameter of 2φ; that is, twice as large and 1/4 of the intensity. Thus a 5W DPSS laser is eight times "brighter" (more intense). This intensity is key for nonlinear optics.

Nonlinear optics

A summary of simple nonlinear conversion processes is shown in Figure 2. Frequency doubling produces one 532nm SHG photon from two 1064nm infrared photons. Doubling efficiencies are typically 50 percent, although very high–beam–quality lasers can achieve up to 80 percent conversion of fundamental into second harmonic. Frequency quadrupling utilizes the same process as frequency doubling, but doubles the second–harmonic at 532 nm to the fourth–harmonic at 266 nm. Typical efficiencies here are significantly lower, with approximately only 25 percent of the second harmonic converted to the fourth. Sum–frequency mixing is a more sophisticated case of the frequency doubling process. In doubling, two photons of the same frequency add to produce a single photon of twice the frequency. In the more general case, the original two photons can be of different frequencies. Frequency tripling is a good example of this process. While it is possible to di rectly triple by combining three photons at 1064 nm to produce one photon at 355 nm, this di rect process is in efficient. Instead, a two–step pro cess of doubling to produce 532 nm followed by sum mixing with 1064 nm is used. The two–step pro cess can typically convert 30 percent of the fundamental to third harmonic.

Difference–frequency mixing is the reverse process to sum–mixing, and is related to optical parametric oscillators (OPOs). OPOs offer solid–state tunability for lasers, and over the last several years have largely replaced the tunable dye laser. Like lasers, OPOs have a resonant cavity and crystal gain medium. However the crystal is composed of a nonlinear material. The signal and idler outputs are generated by interactions between the intense pump and weak quantum noise at the signal and idler frequencies. OPOs are the ultimate tunable laser, giving widely tunable output across the near UV, visible and IR spectrum.

Efficiency and brightness

The absolute best conversion efficiency that can ever be achieved for most second–order nonlinear processes (doubling, sum mixing, etc) depends solely upon the so–called "brightness," B parameter. Eimerl1 defines the lumped parameter "brightness." Brightness couples the optical brightness of the pump laser with the nonlinear characteristics such as angular acceptance, Deff and walkoff.

null

deff is the nonlinear coefficient, M2 is the beam quality (times diffraction limit), and λp is the pump wavelength. The angular sensitivity, β = δk/δθ, describes the dependence of efficiency upon small angular changes between pump and crystal axes, β is inversely proportional to the crystal's acceptance angle and proportional to the walkoff angle.

Figure 3 compares the second harmonic conversion efficiency of two real lasers using type–II LBO and type–II KTP doublers with the theoretical brightness curve. Both lasers are CW–pumped and repetitively Q–switched at 10 kHz. The lamp–pumped laser produces 50 W with M2 ~ 2, in a 200ns pulse, while the DPSS laser is only 5 W in a 10ns pulse with M2 ~ 1 beam quality. Using the three data points, one can readily extract others by noting that brightness is proportional to the pump laser's power, pulse energy and beam quality, and inversely proportional to repetition rate and wavelength.

For example, if a laser produces 50 percent doubling efficiency, the brightness must be doubled just to increase the efficiency to 60 percent. To achieve 80 percent efficiency, brightness must be increased by an order of magnitude. If power is the only "knob" available, this will be an expensive proposition; pulse duration or beam quality is often a more profitable parameter to tweak. Bright ness increases as the square of M2 parameter, so even a small increase in M2 gives excellent leverage to improve brightness and efficiency, for nonlinear optics just as in materials processing.

Selecting the crystal

For the nonlinear crystal, brightness is proportional to the nonlinear coefficient, acceptance angle and dn/dT, and inversely proportional to walkoff angle, refractive index and angular sensitivity. Some materials, like KTP, can tolerate relatively poor beam quality and still produce good efficiency. This characteristic is largely related to acceptance angle. Figure 4 illustrates the optimum beam waist size for Type–II phase matching in LBO as a function of optimum focus, degree of walkoff and acceptance angle as a function of the crystal length.

While focusing can increase intensity, acceptance angle and walkoff can limit the interaction length over which this is useful in nonlinear conversion. In this case, tighter focusing will not increase efficiency, as the effective interaction length is reduced. In some cases walkoff differs in the two axes of the crystal, so an elliptical pump beam can improve efficiency. Walkoff occurs because fundamental and second–harmonic are ordinary and extraordinary rays within the crystal and therefore diverge, which reduces the overlap between them with increasing crystal length. For a KTP doubler β = 50,000, Deff = 3.18 pm/V, walkoff ρ = 0.27° and Kw ~ 5 GW–1/2. For LBO type–I doubling, β = 40,000, Deff = 0.88 pm/V, walkoff ρ = 0, and Kw ~ 2.3GW–1/2. As shown in Figure 3, the higher nonlinearity in KTP gives a substantial increase in brightness and efficiency over LBO. In selecting a nonlinear crystal, one must also beware of optical damage, especially using the small focal spots typically required for low–power lasers. Ma terials like KTP and LNbO3 have very high nonlinear coefficients but unfortunately also exhibit low damage thresholds (~10 and ~100 times lower than LBO, respectively).

Future

There are a number of materials processing applications that do not benefit from increased peak power. Some applications require longer bursts of laser energy to melt material rather than ablate it. These processes include welding, marking silicon and trimming. It is currently difficult to use nonlinear optics with low peak power sources. How ever, emerging technologies are overcoming this limitation. Designer nonlinear materials take advantage of effects like periodic poling to overcome the acceptance angle and walkoff limitations, and in a sense change the fundamental brightness parameter that limits nonlinear conversion efficiency. Periodic poling enables materials with very high nonlinearities to be customized for a given process. Using a CW source and simple single–pass doubling, PPLN exceeds the efficiency of conventional doublers like KTP by at least two orders of magnitude.

Only five years ago it was difficult to imagine a DPSS UV laser with more than a few milliwatts of output power. Now we have commercial devices producing up to 10W at 355 nm for via–hole drilling. Nonlinear optical methods have already made a strong contribution to industrial lasers, and it is likely that wavelength will become the new knob with which to fine tune next–generation industrial laser processes. Over the coming years, we will see OPOs used in a number of materials processing applications, primarily for their ability to tune a process between pure ablation and thermal transfer, or any combination in–between. As shown in Figure 5, the user will be able to selectively target key optical absorption features of the material in question, using "any color you like."

REFERENCE

1. D. Eimerl; IEEE Journal of Quantum Elec tronics, Vol. QE–23, No. 5, 1987, pp 575– 592.

Dr. Larry Marshall is the CEO of Lightbit Corporation. Contact him at larry@lightbit. com or learn about his company at www.lightbit. com.