Online thickness measurement of flat products

Reinhard Noll and Michael Krauhausen

Multi-sensor systems are capable of performing complex online measuring and inspection tasks on production lines

The majority of modern production processes have reached such a high degree of automation that the involved process steps, as well as the quality of the manufactured products, have to be inspected on a routine basis. Online measurements offer the shortest possible reaction times for process control. Laser measuring methods are ideal for this task for a number of reasons: no mechanical contact to the specimen is required, fast measuring speed, independence to ambient light and fast adaptation to varying surfaces of the specimens. Over the years, laser sensors for the determination of geometric workpiece features were developed that achieve a high level of precision and measuring frequency performance for online measurements.

The most important optical measuring method for the absolute determination of geometric features of workpieces in one, two or three dimensions is based on the triangulation principle. Figure 1 shows state-of-the-art sensors based on triangulation: a) light section sensor where the laser beam is shaped to form a light sheet to measure contours and b) distance measuring sensor with a single collimated laser beam.

Table 1 gives an overview of the typical technical data of triangulation sensors developed at Fraunhofer ILT in cooperation with its partner NoKra Optische Prüftechnik und Automation (Baesweiler, Germany).

The diode lasers used for these sensors achieve lifetimes of up to 100,000 hours. Both sensor types can be externally triggered, thus enabling the synchronous measuring with multiple sensor set-ups on moving objects.

Figure 2 shows the measuring principle where two laser triangulation sensors measure simultaneously on the top and bottom side of a running sheet. The sensors are installed downstream of a rolling stand. The determined thickness value is used for the online control of the rolling gap. The technical data of a high-precision laser thickness measuring system are given in Table 2.

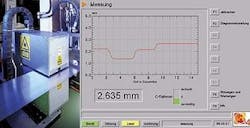

Thickness measurement precision of 2.2 µm is achieved on moving sheets under routine production conditions. Figure 3a shows a view of the two laser sensors mounted on a C-frame measuring online the thickness of steel sheets. Figure 3b depicts the display of the measured thickness values on the monitor of the operation center.

Dr. Reinhard Noll is head of the department laser metrology of the Fraunhofer Institute for Laser Technology (Aachen, Germany). He can be contacted at Tel: +49 241 8906138, Fax: +49 241 8906121 or e-mail: [email protected]. Dipl.-Ing. Michael Krauhausen is managing director of NoKra Optische Prüftechnik und Automation GmbH (Baesweiler, Germany). He can be contacted at Tel: +49 02401 607714, Fax: +49 2401 607711 or e-mail: [email protected].