FEMTOprint develops glass-based puncture tool for retinal vein cannulation

LUGANO, SWITZERLAND – FEMTOprint SA, in collaboration with Instant-Lab, Galatea-Lab, and Hospital Jules-Gonin (all in Lausanne, Switzerland), has developed a challenging passive compliant tool for retinal vein occlusion (RVO), which is a major cause of vision loss in patients over 50 years old. RVO can be treated by cannulation of the retinal vein to remove clots—however, cannulation of small retinal veins is challenging, as the required puncture force (~10 mN) is well below human sensing capability and the dimensions of the tool need to be compatible with the vein.

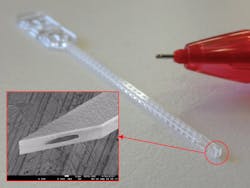

FIGURE 1. Detail of the puncture tool and 3D cross pivot are shown. (Courtesy: Instant-Lab and Galatea-Lab)

Recognizing this, the group conceived, manufactured, and tested a passive compliant tool for RVO (FIGURE 1) that has predetermined stroke and threshold force, allowing safe and precise puncturing independent of the actuation input.

The tool has been specifically designed to have maximum stroke of 500 μm and threshold force of 25 mN.

The device has been monolithically fabricated through the advanced FEMTOPRINT technology, which enables production of high-precise 3D glass microdevices with extreme accuracy and aspect ratio. The process uses a femtosecond laser to “print” the device inside glass, followed by a selective chemical etching. The etching rate of the exposed glass is orders of magnitude higher than the unexposed glass, enabling the desired 3D structure to be developed.

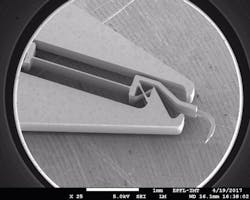

Such technology allows for a high level of integration in very small volumes that goes well beyond what can be achieved with other high-end fabrication techniques. Relying on glass also allows for small, lightweight, bio- and CT/MRI- as well as optical microscope-compatible, and even flexible and optimized systems. The integration of microfluidics to secure drug delivery in this device has been possible, in addition to adding functionalities such embedded force control in a monolith. Allowing to work in the volume and to create microfluidic channels, one end of the device can be connected to a needle having an embedded microfluidic channel that cannulates the vein laterally (FIGURE 2).

FIGURE 2. The puncture tool, with detail of the needle integrating a microfluidic channel (inset), is shown. (Copyright: FEMTOprint SA, Galatea Lab, and InstantLab)

The tool uses a bistable mechanism, having two stable states and one unstable state, which releases a constant amount of energy when it passes from its unstable state to a stable state. It follows that a threshold force can be obtained by limiting the stroke of the mechanism. This ensures safe and precise cannulation of the retinal vein; assuming a very thin wall, with puncturing force lower than the threshold force, cannulation is guaranteed.

The tool already successfully cannulated pig eye retinal veins. Made out of glass (chosen for its biocompatibility, transparency, and favorable elastic properties), it can be used in either standalone mode or mounted onto a robotic system.

This project, supported by CTI - Swiss Commission for Technology and Innovation, is opening a wide range of new opportunities in the medical-technology field, for which the company FEMTOprint has an ISO 13485:2016-compliant Quality Management System, certified in September 2017.

To learn more about FEMTOPRINT, please visit https://goo.gl/jy4KP9.