II-VI opens applications lab in Detroit for laser materials processing

PITTSBURGH, PA—Laser materials processing solutions manufacturer II-VI Incorporated has opened its applications laboratory in Detroit, MI.

Advances in laser processing capabilities on automotive production lines are accelerating and driving increased collaboration between industrial laser specialists and car manufacturers. The company’s new applications laboratory provides close customer support on laser materials processing with hands-on training, applications consulting, and detailed feasibility studies based on the company’s applications engineers and the advanced capabilities of its laser processing heads.

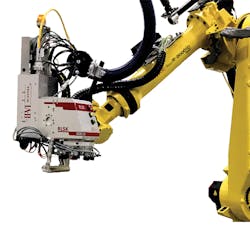

The new applications lab will have a RLSK remote welding head.

The applications laboratory is equipped with the latest II-VI HIGHYAG laser processing heads for welding and brazing. This includes the RLSK remote laser welding head with its new seam tracking feature (FIGURE) and the BIMO, which allows adjustment of the laser beam focal diameter and position during or in-between welds. By combining these with a multikilowatt laser source, an industrial robot, and a rotation table, processes can be developed for a wide range of configurations and materials, including aluminum, zinc-coated steel, and hot-stamped, aluminum-silicon coated steel.

For more information, please visit www.ii-vi.com.