Laser processing method could print electronic components like newspaper

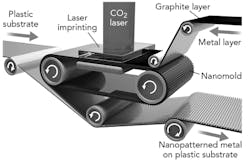

WEST LAFAYETTE, IN – Researchers at Purdue University have developed a laser processing technique that is similar to newspaper printing to form smoother and more flexible metals for making ultrafast electronic devices. It combines tools already used in industry for manufacturing metals on a large scale, but uses the speed and precision of roll-to-roll newspaper printing (FIGURE 1).

FIGURE 1. Roll-to-roll laser-induced superplasticity, a new fabrication method, prints metals at the nanoscale needed for making electronic devices ultrafast. (Courtesy: Purdue University/Ramses Martinez)

Cell phones, laptops, tablets, and many other electronics rely on their internal metallic circuits to process information at high speed. Current metal fabrication techniques tend to make these circuits by getting a thin rain of liquid metal drops to pass through a stencil mask in the shape of a circuit. “Unfortunately, this fabrication technique generates metallic circuits with rough surfaces, causing our electronic devices to heat up and drain their batteries faster,” explains Ramses Martinez, assistant professor of industrial engineering and biomedical engineering at Purdue.

Future ultrafast devices also will require much smaller metal components, which calls for a higher resolution to make them at these nanoscale sizes. “Forming metals with increasingly smaller shapes requires molds with higher and higher definition, until you reach the nanoscale size,” Martinez says. “Adding the latest advances in nanotechnology requires us to pattern metals in sizes that are even smaller than the grains they are made of. It’s like making a sand castle smaller than a grain of sand.”

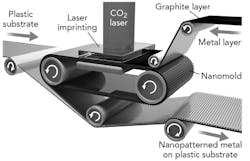

The researchers have addressed the roughness and low-resolution issues with a large-scale fabrication method that enables the forming of smooth metallic circuits at the nanoscale using conventional carbon-dioxide (CO2) lasers, which are already common for industrial cutting and engraving.

FIGURE 2. Purdue researchers have developed a new technique that prints metals like newspapers, making them smoother and more flexible for better current flow throughout a metallic circuit. (Courtesy: Purdue University/Ramses Martinez)

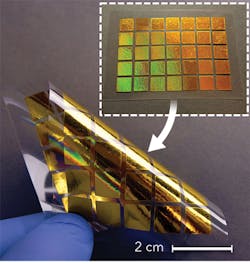

The fabrication method, called roll-to-roll laser-induced superplasticity, uses a rolling stamp like the ones used to print newspapers at high speed (FIGURE 2). The technique can induce, for a brief period of time, “superelastic” behavior to different metals by applying high-energy laser shots, which enables the metal to flow into the nanoscale features of the rolling stamp—circumventing the formability limit.

“In the future, the roll-to-roll fabrication of devices using our technique could enable the creation of touchscreens covered with nanostructures capable of interacting with light and generating 3D images, as well as the cost-effective fabrication of more-sensitive biosensors,” Martinez says.

Full details of the work appear in the journal Nano Letters.