Laser joining of metal and plastic

Seiji Katayama

Metals are strong and ductile, and plastics are light and easily formable. Recently, the importance of joining a metal and a plastic has increased by making the best use of these superior properties in various manufacturing fields. Joints are conventionally produced by using adhesive bonds or glues, or bolts, screws, and rivets. However, there are some problems in adhesive bonding with glues, such as harmful effects due to volatile organic compound (VOC) emission, longer production periods, scattered values in the joint strength, weak peel strength, and careful storage of glues. Mechanical bonding processes have other problems: reduced design flexibility, difficulty manufacturing a flat surface product, requirement of additional processes, increased weight, and low mass production.

LAMP Joining Procedures

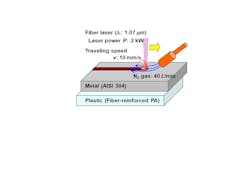

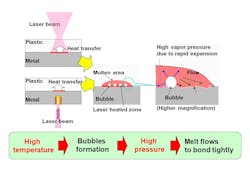

A laser joining technology for direct-bonding a metal and a plastic, named laser-assisted metal and plastic (LAMP) joining, has been developed to overcome the above drawbacks. LAMP joining is performed by melting the plastic near the joint interface and then forming small bubbles in the melted plastic by utilizing a simple lap joint, as shown in FIGURE 1. The surfaces of plastic sheets and metal plates are cleaned with alcohol but other surface treatments are not required. If the plastic sheet has more than 60% transparency, it may be placed at the upper side, as indicated in FIGURE 1a. The transmitted laser beam is absorbed to heat the metal surface, and the plastic near the joint can be melted to form bubbles by the heat conducted from the metal. A shielding gas should be used to keep the top plastic sheet surface clean and cool. The procedure illustrated in FIGURE 1b can be utilized on any plastic, such as GFRP, CFRP of high laser absorption. If the metal plate is thick, a partially penetrated weld should be produced to heat the plastic near the joint interface. The metal interface near the lap joint is not melted, but the plastic on the metal plate is melted to form small bubbles.

Joint characteristics

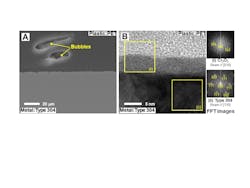

The LAMP joining is applicable to bond thermo-plastics, especially engineering plastics, to any metal. In both processes (FIGURE 1), a strong LAMP joint is characterized by the formation of small bubbles in the plastic near the joint, which should be heated above the decomposition temperature of the plastic. The samples of polyethylene terephthalate (PET) plastic to AISI 304 stainless steel produced with the laser beam are shown in FIGURE 2. Small bubbles are formed in the laser irradiated area. In the tensile shear test, the strong joints show the elongation of the base PET plastic sheet (FIGURE 2) or the fracture of the base plastic sheet. The tensile shear loads (strengths) of samples of PET sheets of 30 mm width and 2 mm thickness to Type 304 plates of 30 mm width and 3 mm thickness possess 3000 N, where the base PET is elongated. This LAMP joining technology is applicable to many combinations of metals such as steels, titanium, and aluminum alloys, and plastics such as PET, polyamide (PA), and polycarbonate (PC). The formation of small bubbles of 0.5 mm or less due to rapid temperature history induced by laser is important because the strengths of the LAMP joints are low when the bubbles are too small and high when the sizes of bubbles are large.Joining mechanisms

Scanning electron microscope (SEM) and transmission electron microscope (TEM) photos near the lap joint between PET plastic sheet and Type 304 steel plate are exhibited in FIGURE 3. The plastic near the joint interface is melted to bond the heated steel surface. The plastic is bonded through the oxide film covered with the metal surface.Advantages

There are many advantages in LAMP joining:

- The joining time is short.

- Automation is easy.

- The joint is stable for a long period because of the direct utilization of a base plastic.

- The effect of the metal surface is small.

- The mechanical properties of joints produced under the proper conditions have a small scatter in value.

- The cost and size are not limited because no glues, volts, or rivets are used.

- There is no need for care and storage of glues or mechanical parts.

Evolution of LAMP joining

The automobile and transportation industries and the electric or electronics industries are interested in LAMP joining technology. Mechanical tests – such as tensile shear test, peel test, fatigue test, the leakage test of gas, and the thermal cycles test between low and high temperatures – have been carried out to evaluate the properties of the joints. It is also confirmed that LAMP joining is applicable to the joining of dissimilar metals with a plastic intermediate layer sheet in terms of the preventive means of local electric-physical corrosion in the metals. A variety of combinations of plastics and metals have been investigated, and some are approaching practical applications. There are some reported technology gaps in the combinations of metals and plastics in the LAMP joining, owing to the newness of the technology. It is important to know that the joint properties are governed mainly by the kind of the plastics and the laser irradiation conditions.

Professor Seiji Katayama is with JWRI, Osaka University, at [email protected].