Lasers in flexible packaging

Santa Clara, CA and St Paul, MN-The development of CO2 lasers with an output wavelength of 10.25 microns has been one of the factors enabling the market for laser converting of flexible packaging materials to expand significantly. In particular, this wavelength coincides with an absorption peak in biaxially oriented polypropylene (BOPP), a material widely used in flexible packaging. At ANTEC 2004 (Annual Technical Conference/Society of Plastic Engineers), applications engineers from Coherent Inc. (www.coherent.com) and LasX Industries Inc. (www.lasx.com) demonstrated results showing that 10.25-micron lasers could cut and score these films at speeds up to three times faster than the conventional 10.6-micron output. As a result, flexible packaging companies are now specifying laser scoring for easy-open convenience.

Since then, LasX has been a leading proponent of this new wavelength. This company is a prominent player in laser converting providing both LaserSharp converting equipment solutions as well as contract processing. According to LasX Founder and President Bill Dinauer, “Product cycles are now too short to justify tooling for on-shore converting operations. At the same time, the advent of compact CO2 lasers has enabled the implementation of ‘digital converting’-computer-controlled laser converting. We believe that laser digital converting is now roughly at the same stage as sheet metal laser cutting in the early 1980s, that is, on the cusp of widespread acceptance in production applications.”

LasX was one of the first companies to implement 10.25-micron lasers for use on BOPP and laminated polymer films. Polypropylene/polyethylene (PP/PE) is a common laminate film structure used in food packaging where the PP outer layer provides for package strength and printing, and the inner PE layer delivers a sealant for the packaged product. Dinauer notes that the increased production speed obtained from 10.25-micron lasers allows smaller, less costly lasers to be specified, a significant factor in justifying the economics of laser digital converting.

Much of the LaserSharp equipment sold by LasX for flexible packaging applications is in the form of retrofits of existing slitter-rewinders. This strategy has proved successful because it integrates existing functions of the slitter-rewinder with laser digital converting processes such as laser scoring and perforating, thereby giving converters access to multiple processes at no additional labor/time surcharge.

For more information contact Sri Venkat at Coherent Inc., [email protected] or Bill Dinauer at LasX Industries, [email protected].

Kiss-cutting high-density foam

Mukilteo, WA-Many years ago, when Coherent General was still an entity, they developed-in conjunction with a robot manufacturer-a CO2 laser based system that kiss-cut automobile dashboards to create a weakened area for an activated airbag to explode through. The idea was to just penetrate one or two layers of the dashboard material without cutting through to the visible surface. While not the first laser kiss-cutting application, it certainly was a creative use for this materials processing technology.

Today many industrial and consumer products use adhesive-backed, high-density polyethylene (PE) foams to seal against moisture, light, and dust. In the consumer electronics arena, these foams provide electrical and thermal insulation properties in addition to cushioning against vibration and shock. Aircraft manufacturers use polyethylene foam for sound and vibration deadening between bulkheads. In marine applications, closed cell PE foam serves the same purpose while adding buoyancy to watercraft. If your home has laminate flooring, a PE foam underlayment was first installed to act as a moisture barrier and provide cushioning.

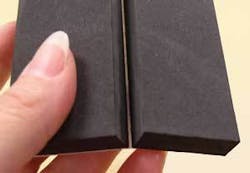

The laser process requested for this particular application is kiss-cutting, where the laser cuts through the high-density foam (or other material) without cutting the paper liner. Achieving a successful kiss-cut involves finding the proper balance of laser power and motion to obtain consistent cuts through the material without damaging the backing or liner. This is especially crucial in web converting or labeling applications where significant downtime is incurred if the liner (web) is cut or broken and must be re-threaded through the machine.

At SYNRAD Inc. applications engineers used 100 watts of CO2 power and a 20-PSI nitrogen assist to kiss-cut sheets of 0.5-in. thick high-density PE foam (without damaging the Kraft paper backing) at a rate of 120 inches per minute. Laser based processing allows manufacturers to economically produce standard and custom shapes or short production runs without the need to physically change, or maintain, their traditional steel cutting dies.

Hybrid laser welding technology goes commercial

Brunswick, ME - Maine-based hybrid laser welding technology company PLSystems begins 2007 with a major new collaborative partner. The company has recently signed an agreement with ESAB Welding & Cutting, allowing ESAB to integrate PLSystems’ patented closed-loop control system into ESAB’s mechanized laser welding systems. The agreement is the result of a four-year collaboration to develop and commercialize a hybrid laser welding system that combines the benefits of laser welding and GMAW.

PLSystems markets hybrid laser welding technology developed by two separate Maine-based research and development companies, Applied Thermal Sciences (ATS) and Technology Systems Inc. (TSI). Since FY ’01, ATS and TSI have been awarded $12.75 million in Navy research funds for the Office of Naval Research (ONR) Laser Fabricated Ship Structure Program, technology commercialized by PLSystems.

PLSystems has been operating since 2005, providing laser fabricated panels and beams for evaluation by the ONR Ship Structure Program. The collaboration with ESAB Welding & Cutting to develop hybrid laser welding systems for industry is the next step of a broad-based rollout of this technology from R&D to commercialization.

“This is an excellent example of a small, technology-intensive business partnering with a major commercial corporation to form a partnership that enables leading-edge technology to rapidly enter the marketplace,” said David Patch, president of PLSystems. “In this case, it further leverages the technology that was developed for Navy shipbuilding purposes by providing the technology to the much broader commercial market.”

Hybrid laser welding technology produces structural beams with increased accuracy and minimal distortion. Also, hybrid laser welding technology produces steel sandwich panels with minimal distortion and high strength-to-weight ratio. PLSystems laser welded T-beams and steel sandwich panels have commercial applications across several industries, including construction, transportation, and aviation sectors.

Find out more at www.plsystems.us.