Singapore’s laser processing industry

Laser processing is used in many sectors of the Singapore manufacturing industry, and government-funded research institutes work with local industry to develop and validate laser-processing methodology

Keng Leong

The Republic of Singapore is an island at the southern tip of the Malay peninsula. With a size of about 700 km2, it is the smallest nation in Southeast Asia. English is the official language. Singapore has a high degree of industrialization and more than $300 billion of foreign investments. The multiracial population of this former British colony and current-day democratic parliamentary republic enjoys the highest quality of life in Asia. Being natural-resource poor and space-limited, Singapore has focused on finance, trade, high-value manufacturing, and manufacturing services in a number of sectors including the biomedical sciences, chemicals, electronics, precision engineering, and transport engineering (aerospace, marine, land transport, and oil-field equipment).

Laser processing is commonly used in many sectors of the local manufacturing industry, and government-funded research institutes work with local industry to develop and validate laser processing methodology. There is a thriving local laser manufacturing community with both home-grown and foreign companies; for example, more than 10 system-integration companies incorporate lasers into systems for laser marking and cutting.

Most of the demand is related to the local electronics, disk manufacturing, pharmaceutical, and medical instrument industries. More than a dozen components and equipment manufacturers use laser cutting, marking, or welding. There is a substantial local aerospace maintenance and repair industry where laser cladding and heat treatment are used (see table).

Laser manufacturers

Lasers are manufactured or assembled locally by several manufacturers. Hylax Hypertronics is a home-grown laser company making CO2, Nd:YAG, and diode-pumped solid-state lasers mainly for its marking systems. This company has a substantial part of the low-to-medium-price marking systems market in Southeast Asia.

Rofin has a center in Singapore that assembles high-value marking systems and services the Southeast Asian region, offering sales, training, service, and spare parts (Rofin-Baasel Singapore Pte. Ltd.). Rofin-Baasel dominates the high-end marking applications market in the region for semiconductor, electronics, and medical industries and supplies laser marking systems to several system integrators. Rofin high-power lasers are used in aerospace-component repair in Singapore and in automotive-component manufacturing in the region.

TRUMPF has a sales office and demonstration facility with a Nd:YAG laser on a robot arm. It competes with other metal working companies and supplies laser cutting systems to the local industry. German-based EOS, a supplier of laser sintering systems for rapid prototyping and manufacturing, will establish a support center later this year to address the rapid growth of its user base (>100) in the Asia-Pacific region (see Figure 1).

Lumonics also has a sales and service office with industrial customers using its range of laser drilling systems. Additionally, a number of industrial laser manufacturers are represented in Singapore through established laser distributors. For example, Coherent is distributed through Laser-21, Lamda Physik and Newport/Spectra Physics are represented through Zugo Photonics, and Clark-MXR is represented through Acexon.

Research and development

Two government-funded and well-equipped research institutes carry out laser processing research and development (R&D). The Data Storage Institute, one of the 14 research institutes of the Agency for Science, Technology and Research (A*STAR), has an Optical Materials and Systems Division that performs research on laser interactions with materials and industrial applications of laser micro- and nanoprocessing and characterization for the data-storage and electronics industries. Its facility has a broad range of pulsed UV to IR lasers. Students from local universities participate with the full-time staff in the R&D activities, and some of the development projects are carried out in collaboration with local industry.

The Singapore Institute of Manufacturing Technology (SIMTech) is a multidisciplinary research organization that develops high-value manufacturing technology and human capital to enhance the competitiveness of Singapore’s manufacturing industry through collaborations with multinationals and local companies. It works in various industry sectors such as electronics, precision engineering, aerospace, automotive, marine, and logistics. SIMTech is also one of the 14 research institutes of A*STAR (see www.a-star.edu.sg).

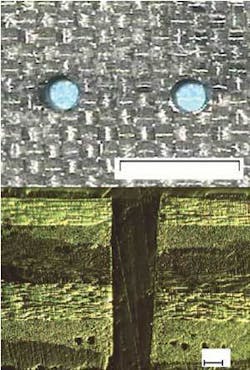

SIMTech has broad laser capabilities to address the range of industrial interests. Its 10 in-house laser systems include femtosecond, DPSS UV, 200-W fiber laser, and a 3-kW CO2 laser. R&D activities encompass both micro- and macroprocessing, including microprocessing of brittle materials such as silicon and glass, precision dicing and drilling of electronic substrates, and machining of composites materials, laser cutting, drilling, welding, and laser additive processes (cladding). SIMTech has an established reputation working with industry and has many collaborative and technology-transfer projects with companies in the different industrial sectors. An example of collaborative work with industry is the laser drilling of precision holes in composite material (see Figure 2).

Recently, emphasis has been placed on the laser additive process, which enables the building of nearly net-shaped parts using powder materials, along with the advantage of depositing more than one material at a time to produce graded materials with tailored mechanical properties. With a newly installed powder-delivery nozzle and twin powder hopper, collaborative work with several aerospace maintenance repair overhaul companies has been initiated.

David K. Y. Low, acting group manager of the Machining Technology Group, commented that SIMTech’s portfolio of R&D projects in laser processing closely matches industry’s needs with near- and medium-term targets. For long-term targets (more than five years), SIMTech works closely with local and overseas universities. Overall, research plans address the increasing trend of laser processing technology adoption for advanced manufacturing in Singapore.

System integrators

The majority of system integrators, such as MIT and IDI, supply high-value systems for the electronics industry to laser mark ICs and wafers. Most of these companies sell their systems worldwide to semiconductor manufacturers. MIT is an automation systems manufacturer focused on the semiconductor sector. Its equipment is used for marking and inspection of wafers and ICs. MIT has utilized Rofin-Baasel lasers for more than 10 years to produce systems for marking.

A more conventional laser system integrator is Resem Technologies, which specializes in stencil-cutting systems, glovebox welders, and precision multiaxis welding systems. Derrick Poh, managing director, emphasized that the Resem system has been able to attract the major stencil makers because of its high speed and hole roundness. Resem sells mainly to companies in Singapore, China, India, Japan, and Southeast Asia. It has been successful in placing its high-value glovebox welders to manufacturers of microwave and telecommunications devices. Resem has more than 50 cutting and welding systems in the field.

Users

Many of the laser users in Singapore are metalworking companies producing high-value systems for the disk-drive and electronics industries. ETLA builds systems to assemble and test disk drives for multinational disk-drive manufacturers, other high-value system housings, and equipment for the semiconductor and medical industries.

The company started as a metal-fabrication shop. It has grown into a full contract equipment manufacturer with a metalworking facility that uses 4-kW laser cutting systems from TRUMPF to cut different sizes of stainless-steel panels for equipment housings. Nesting software minimizes scrap, and several shifts per day ensures adequate throughput.

Conventional manual welding is still used to join the housing components. K. C. Leong, COO of ETLA, expressed a strong interest in utilizing flexible laser welding to increase weld quality and throughput. Although, one of the benefits of laser welding is high speed for mass production, Leong places a higher value on flexibility and quality when applied to low-volume, high-value products that ETLA produces.

Singapore has growing pharmaceutical and medical-instrument industries. Laser marking is used by many companies to mark packaging for pharmaceutical products. Plastic and foil surfaces are the major materials marked. Siemens Medical Instruments, one of the biggest hearing-instrument manufacturers, primarily uses lasers to mark hearing aids. Laser marking has mostly replaced pad printing with its flexibility, permanence of marking, and tamper-proof properties. The Singapore plant also uses lasers for stripping the miniature wires used in the hearing aid devices.

There is a thriving aerospace maintenance repair and overhaul industry. Many companies participate in this sector, and several use high-power lasers for cladding and heat treatment in the repair of aerospace turbine engine components. Laser drilling is also used in the manufacture of some components.

Lasers play a significant role in the manufacture of high-value products in Singapore. Although low-power lasers for marking dominates, there are many multikilowatt CO2 lasers used for cutting. Other applications in cladding, heat treatment, and welding are growing in importance. The conventional American opinion of job and factory loss to low-cost-labor countries such as China is contradicted in Singapore. Singapore has one of the highest labor costs in the region, but its factories making high-value products with the aid of laser processing are competitive worldwide.