Welding with a supermodulated laser

Using supermodulated output power offers advantages in processing speeds and quality of welding and cutting compared to conventional laser types

Helen Walker

Nd:YAG lasers for materials processing generally fall into two categories: high-power continuous-wave (CW) lasers, in powers from around 500W to 6kW, and pulsed lasers with average powers up to about 500W. The output from a conventional pulsed laser would typically be similar to that shown in Figure 1a, with short peaks of several kilowatts, but much lower average power. Continuous-wave lasers also often can operate in a ‘modulated’ mode, where the CW laser light is delivered in gated pulses of varying frequency, up to the maximum CW power produced (see Figure 1b).

A new laser type (with average power to 2kW) produces ‘supermodulated’ output power, where the light generated is essentially CW, but the laser can produce a pulsed output with a peak pulse power of twice the average CW power (see Figure 1c). This is done by storing some energy in the power supply during the off time in the pulse cycle, which is then released during the peak power part of the cycle. Manufacturers claim that use of supermodulated output power offers advantages in processing speeds and quality of welding and cutting compared to conventional laser types.

At The Welding Institute (TWI; Cambridge, UK; www.twi.co.uk), a JK1002 supermodulated laser-manufactured by GSI Group and producing a maximum average power of 1kW with peak pulse power of 2kW in either square- or sine-wave form-was used to weld three materials: stainless steel, aluminum, and zinc-coated steel. Laser welding of stainless steel is relatively common, but these welds can be prone to porosity formation in the weld. The effects of supermodulation on maximum welding speed and weld quality were investigated.

Laser welding of aluminum can be difficult at low input energies due to problems with the light reflecting off the material surface. A minimum power density is required to achieve coupling of the light with the surface, and in thin sheet overheating of the aluminum and excessive melting can occur once coupling is established. Trials were carried out to investigate whether supermodulation could be used to improve coupling at relatively low heat inputs.

Laser welding of zinc-coated steel is of considerable interest to the automotive industry for manufacture of car bodies, mainly due to the fast welding speeds that can be achieved. However, it is usually considered difficult to produce good-quality laser welded lap joints in zinc-coated steel without a controlled gap between the parts, which is not easy to achieve reliably and consistently in production. The welds are susceptible to blowholes and spatter caused by vaporization of the zinc coatings on the inside surfaces of the joint.

It was therefore of interest to investigate whether supermodulation could be used to improve weld quality, particularly when welding without a gap between the sheets, a configuration much easier to achieve in production. Previous work on zinc-coated steel found that even welds with severe blowholes passed tensile testing (that is, failure occurred in the parent material rather than the weld), so the aim of this work was to produce welds with good external appearance and minimal spatter.

Experimental approach

The laser delivers the light to the workpiece via a 0.6-mm-diameter optical fiber using 200- and 100-mm-focal-length focusing optics that produced 0.6- and 0.3-mm-diameter focused spots, respectively, at the material surface. The laser was used at 1-kW average power, with varying travel speed, modulation mode (including CW operation), and modulation frequency. For the welds made on stainless steel and aluminum 0.3-mm focused spot diameters were used, and for the trials on the zinc-coated steel 0.6- and 0.3-mm diameters used. Welds were also produced at various power levels for comparison, using a high-power CW laser that delivered the light through a 0.6-mm-diameter optical fiber and focusing optics delivering similar focused spot diameters.

Bead-on-plate welds were produced in 3-mm-thick 304 stainless steel, and a total of 40 welds were made. Argon shielding gas was supplied through a coaxial nozzle with a trailing shoe and through a channel on the underside of the weld. The resulting weld quality was assessed in terms of porosity and bead profile.

This laser was used at 1-kW average power to produce bead-on-plate welds in 2-mm 1050 aluminum alloy. Argon shielding gas was supplied through a coaxial nozzle and through a channel on the underside of the weld.

Trials were also carried out at 1-kW average power to produce fully penetrating lap stake welds in 0.7-mm-thick zinc-coated steel with 8-µm zinc-coating thickness. The joints were clamped such that there was no gap between the plates. No shielding gas was used for these welds.

Effects in stainless steel

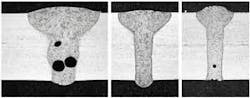

The welds made with modulated mode were narrower welds with smaller fused areas, as would be expected due to the reduced energy input (see Figure 2). It was noted that the square-wave weld beads were often irregular and suffered from undercut, while the sine-wave and CW weld beads were much smoother.

These results showed a significant increase in welding speed with supermodulated compared to CW output, for the same average power (see Figure 3). In sine-wave mode, the increase was about 50 percent and more than doubled in square-wave mode. The speed increase was greatest at the lowest modulation frequency, 200Hz. These speed increases would correspond to a significant reduction in heat input and offer advantages in terms of reducing distortion in laser welded components.

The ‘wine glass’ weld shape produced in CW mode is normally associated with a plume of vaporized weld metal above the laser keyhole. This can scatter the laser energy, resulting in a wider top bead and a reduction in penetration and/or travel speed. The results from this work suggest that the pulsing action inhibits the formation of the plume and the laser is allowed to interact better with the stainless steel, thus improving the process efficiency. This would also explain the relative improvement in square-wave mode at low frequency, giving maximum disruption of the plume, and allowing greater travel speed to be achieved for the same average power.

Porosity levels were very high in the welds made in CW mode, around 18 percent of the weld area. Using supermodulation at 200-Hz frequency, it was possible to reduce the porosity to only 1 percent of the weld area, in both sine- and square-wave modes. Porosity levels generally increased with increasing frequency, and were higher in welds made with sine wave modulation than square wave (see Figure 4).

A comparison weld was produced with a high-power CW laser, using the maximum speed achieved with the JK1002 in pulsed mode, which was 0.9m/min. A power of 1.5kW at the workpiece was required to produce the same weld penetration, and the porosity levels were again very high. Lower porosity can be achieved by using even higher powers to produce greater weld penetration, although clearly this also increases the weld heat input and associated distortion.

These results show that supermodulated lasers may be very useful for reducing porosity in stainless-steel welds. Although the work did not investigate the potential for producing partially penetrating welds, these are generally considered to be more susceptible to porosity than fully penetrating welds, and there may be some further advantage in using the supermodulated laser. The increase in welding speed for a given average power and, hence reduction in heat input, also demonstrates the potential of these lasers for welding of structures susceptible to distortion during welding.

Welding aluminum

It was found that reproducible coupling of the laser beam with the aluminum surface could only be achieved with one condition at low heat input; square-wave modulation mode at 200-Hz frequency. Other pulsed conditions produced some coupling, while 1-kW CW laser light did not couple to the aluminum at all. However, even using the 200-Hz square-wave condition, the slightest variation in focus position and resulting power density caused a loss of coupling, which suggests that the power density is at the minimum limit of that required.

The use of supermodulated laser power improves coupling for welding of aluminum, and should allow welding with lower heat input than for a CW laser, which would be beneficial for thin sheet. However, a slightly higher average power than 1kW may be required to achieve consistent results for production applications.

Welding zinc-coated steel

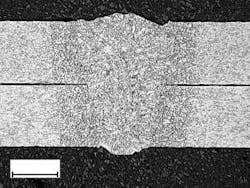

Good-quality lap welds in zinc-coated steel were achieved using various pulsed conditions and a 0.6-mm-diameter focused spot (see Figure 5). Some internal porosity was visible from inspection by radiography, but the external quality was excellent, with no blowholes or surface breaking porosity. As with stainless steel, the fastest welding speed, 1.3 m/min, was achieved using square-wave modulation at 200Hz. Welds made with 1kW CW laser power again needed to be made at a lower speed of 0.4 m/min and contained a number of surface-breaking blowholes (see Figure 6). Use of a 0.3-mm spot size allowed faster welding speeds, but the welds were of very poor quality in either pulsed or CW mode.

Some comparison welds were made at 1.3 m/min using a high-power CW laser, with which 1.2 kW was required to achieve the same penetration. These were also of good external quality, and the weld width was similar to those produced with the JK1002 in square-wave mode.

This suggests that certain process windows exist in terms of power, speed, and spot size, in which good quality welds can be produced in zinc-coated steel using either CW or supermodulated laser power. However, the higher capital cost of the CW laser may be a decision factor.

Use of supermodulated laser power for materials processing can offer the following advantages compared to CW lasers: improvements in weld quality specifically in the reduction of porosity; the ability to produce good quality lap welds with zero gaps in zinc-coated steel; increased welding speeds and, hence, reduced heat input for the same average power, which will benefit distortion critical components in thin sheet; lower capital cost, £107k for the supermodulated, compared to a CW laser, which would be required to match the performance of the JK1002; and improved coupling of the laser light to the surface for welding reflective materials such as aluminum.

Helen Walker ([email protected]) is project leader-technical, laser and sheet processes group at TWI.