The development of structurally sophisticated tablets and capsules for oral medication has enabled pharmaceutical manufacturers to make a wider range of useful drugs available to the public. Laser marking and microprocessing have proven to be key enablers in the production of some of these medications.

Modern drug delivery systems

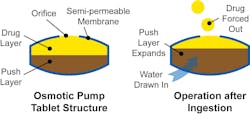

Complex tablets and capsules (collectively called “drug delivery systems”) provide benefits such as accurately controlled time release of medication and enable the use of drug molecules that would otherwise be difficult to administer orally because of poor water solubility. One example is the “osmotic pump,” which typically includes a drug layer and a “push” layer surrounded by a semi-permeable membrane. After ingestion, water enters through the semi-permeable membrane causing the push layer to expand. This forces the medication to be pumped out at a controlled rate through a small orifice in the drug layer side of the membrane (see Figure 1).

The typical orifice size in osmotic pumps ranges from about 600 µm to 1 mm. The tolerances on hole diameter and shape are usually relatively loose, at least by the standards of other precision manufacturing tasks. A nominal 600-µm hole usually has a ±100-µm tolerance on diameter and an allowable ellipticity of 1.0 to 1.5. Holes of these dimensions and tolerances certainly could be produced by purely mechanical means; however, no mechanical method has proven capable of working at throughput rates that are consistent with other stages of the pharmaceutical manufacturing process. In contrast, laser tablet drilling supports throughput rates of up to 100,000 tablets/hour, and can easily produce holes with the necessary dimensional tolerances and cosmetic appearance.

Process overview

The main functional elements of a laser based tablet drilling system produced by Control Micro Systems (Winter Park, FL; www.cmslaser.com) are shown in Figure 2. This particular configuration utilizes two laser drilling stations and can drill either one or both sides of a tablet. Pulsed CO2 lasers in the 100W to 500W range are chosen for this application because their 10.6-µm output is well absorbed by nearly all the organic materials utilized in drug delivery systems; in contrast, many organics are transparent at 1.06 µm. These organics also absorb well in the ultraviolet (UV), but no UV laser can deliver the power necessary to support the required process throughput levels. Pulsed operation is desirable in this application because it delivers high peak power, which enables rapid processing; pulsed operation also minimizes any heat-induced effects, such as discoloration or debris formation.

Initially, tablets are introduced single file on to a conveyor from a bowl feeder. Osmotic pump tablets are typically colored differently on the push layer and drug layer sides, and, in this case, it is desired only to drill the drug layer side. Tablet orientation is determined as product passes by a color sensor. Next, a presence sensor detects the passage of a tablet and then triggers the laser drilling process if the results from the color sensor were that the tablet was facing right side up. Tablets then pass through a machine vision inspection system. A digital image of each passing tablet is acquired and compared against the four possible outcomes (see table). Two of these outcomes constitute a “pass” and two are considered a “reject.”

Rejected tablets are removed from the conveyor by an air-activated blow off system. Because of the speed at which the conveyor moves and the physical response time of the blow off system, the reject mode is activated as soon as a failed tablet is sensed by the vision system. This typically causes one or two tablets ahead of the rejected unit to be expelled as well. Then, the reject state is usually left on until the system sees five tablets in a row that meet either of the two pass criteria. An additional presence sensor downstream from the blow off (not shown) verifies that no tablets are passing through the system when the reject condition is set to “on.” Despite the fact that some good tablets are rejected by this necessarily rigorous approach, the system still typically operates at 98 percent efficiency (tablets in/tablets out).

After transiting the first laser drilling station the tablets are flipped over, and then continue on the conveyor through a second laser drilling station. This second laser drilling station operates in exactly the same way as the first. Its function is to drill any tablets that were wrong-side-up when they passed through the first drilling station. At the end of the line, processed tablets are fed into a collection drum and are considered ready for final coating and printing.

On-the-fly drilling

In order for this system to achieve throughput rates in the 100,000 tablets per hour range, it is necessary to perform tablet drilling “on the fly,” that is, without ever stopping or slowing the forward motion of product on the conveyor. In terms of the laser drilling process, there are two ways to implement this. First, the tablet can be drilled with a single laser pulse when it reaches a predefined spot along the conveyor. This pulse must be of sufficient peak power to remove the entire outer layer of the tablet, and of sufficiently brief duration so that there is no significant tablet motion during the drilling process (otherwise it will yield a slot, rather than a hole).

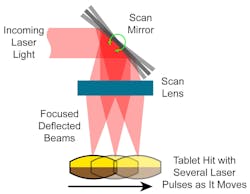

The second approach is to use multiple pulses. To implement this, it is necessary to optically track the motion of the tablet on the conveyor so that each pulse hits the exact same spot on the tablet surface. Typically, this is achieved with a galvanometer-mounted mirror and a scan lens (see Figure 3). The scan lens is configured to maintain the proper beam focus even though the distance from the lens to the tablet changes slightly as product moves along the conveyor. The use of encoder feedback, together with a conveyor design that does not allow slippage of the tablet relative to belt, ensures that each pulse hits the tablet at precisely the same spot.

While the multiple-pulse method increases delivery system complexity, it enables processing using about three to four times less laser power than in the single-pulse case. The use of a lower power, and therefore less costly, laser easily offsets the expense associated with greater system complexity. The maximum number of pulses that can be used to process a single tablet depends upon conveyor speed, the field of view of the scan lens, and laser repetition rate. A typical tablet drilling process utilizes around nine laser pulses in order to drill a single hole.

The exact pulsing characteristics of the laser have a significant impact on the economics and efficiency of the drilling process. In particular, a square wave pulse is preferred over a more triangular shaped pulse, because the former delivers more useful cutting energy per pulse, meaning that it takes fewer of these pulses to perform the processing task. Reducing the necessary pulse count yields a wider process window and greater flexibility. In addition, the reduction of waste energy serves to further minimize any heat-induced damage in the processed material.

Control Micro Systems utilizes Coherent Diamond K Series slab discharge CO2 lasers for many of its tablet drilling systems. In addition to the advantages of square wave pulsing, the Diamond K Series also delivers several other benefits for on-the-fly processing. The ability of these lasers to provide “power on demand” is probably the most important of these. This refers to the capacity to control the laser’s pulsing characteristics, in real time, down to the single pulse level if necessary. In contrast, many industrial lasers operate with a fixed or narrowly variable pulse repetition rate. Moreover, in most other laser types, individual pulses cannot be relied upon to produce consistent results because the laser takes several pulses to reach its steady state performance level. However, the slab discharge design does not have this limitation and can be perfectly pulsed instantaneously. Thus, power on demand is important because it allows the laser to be slaved to any arbitrary (and even variable) feedrate in a real production line. This is substantially simpler than attempting to adjust the mechanics of the conveyor system so that tablets are supplied at exactly the right time to synchronize with a fixed pulse rate laser.

In conclusion, pharmaceutical manufacturing represents an application area in which high throughput and process consistency are absolutely critical. Slab discharge CO2 lasers have proven themselves able to deliver the output characteristics that are necessary to realize both of these ends. Furthermore, these mature lasers offer excellent reliability characteristics and low consumables costs. These are critical concerns as pharmaceutical manufacturers face increasing political and market pressures to reduce overall costs.

About the Author

Frank Gaebler

Director of Product Marketing, Coherent LaserSystems GmbH & Co KG

Frank Gaebler is director of product marketing at Coherent LaserSystems GmbH & Co KG (Lübeck, Germany).