Cutting for crafters and craftsmen

Using Plastics, paper, and wood, This company excels at Non-metal laser cutting

Laureen J. Belleville

Believe it or not, Laser Excel got its start supplying laser cut stencils to “mom and pop” bakeries. The initial application involved cutting designs in 9- and 12-in circles that fit perfectly over a cake that would then be air-brushed to transfer a decoration. From cakes, it grew to cupcakes, cookies, and any standard bakery-sized items. That was in 1982, when the company, then called Stencil Aire, operated one laser and was run by founder Jeff Franklin.

By 1999 the Green Lake, Wisconsin-headquartered company operated 14 lasers and had extended its stencil cutting operation beyond the bakery. The company notes that in the late 1980s the demand for faux finishers had peaked. Faux finishers use paint to create a faux finish, something that looks like wood or paneling, for example; and stencils are used as a tool for this finishing. Indeed, the stencil business was holding its own, and the company was cutting large-format (up to 4 × 8 ft) stencils for these artists.

However, around this time, the company had expanded into the acrylic and signage industries, realizing lasers could be used for more than mylar stencils.

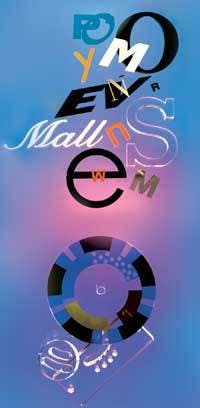

Today, the largest part of the business is devoted to point-of-purchase (POP) displays. In fact, Loni Meiborg, marketing manager, reports, “We do a lot of signage for large, nationwide companies and well-known brands. For example, laser cut components are integratetd into signage seen everyday in stores like Macy’s, Finish Line, and others.”

Another recent POP project involved cutting 1000 display pieces for a well-known shoe company, a good representative of a bulk order for a large company. Processing such an order can take a couple of weeks, but turnaround times depend on the specifications of the order, how busy the company is at the time, and which of the required lasers are available for the job.

For POP, it is the acrylic material, and the company’s ability to turn jobs fast that drives the business. “When a designer is creating a unique and intricate component for a total signage package,” says Meiborg, “they know that laser cutting will produce the highest-quality piece.” A competing method for cutting acrylic signage involves routing. The drawback with this method compared to laser processing is that it does not produce the same quality of clean, polished lines and therefore requires postprocessing. An additional benefit of the systems employed at Laser Excel is the use of multiple heads. Laser cutting is faster on a table with four heads compared to the one-up for routing. Furthermore, the company will cut all the components of a sign, and then the processing department will put it all together as a turnkey operation..

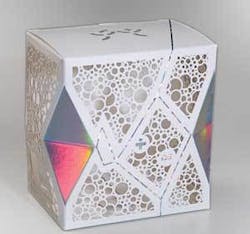

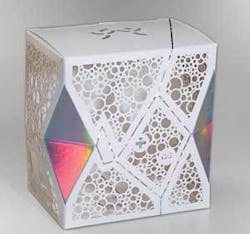

The name change from Stencil Aire to Laser Excel took place in 2000, at which time the company had acquired Santa Rosa, California-based Laser Works. Laser Works had made its name using laser processing for decorative purposes on photo frames and paper products. “That’s when we entered the paper market,” notes Meiborg. “And now the paper/promotional side of the business-greeting cards, corporate, holiday, annual reports, and packaging-is the second largest part of the business.” The company also started its own stationary line, Paper Orchid, that encompases various forms of stationary, invitations, and announcements, which include creative laser cut designs.

The current laser count is 23 and comprises the following systems, which range in power from 80 to 4000 W: one M48-2 and one Diamond K500 lasers from Coherent; three FH1500/2, four FH1500, and two SL2200 lasers from PRC Laser; two Apollo lasers; seven MD4000 lasers from OEI; and three Preco Eagle 500 lasers. The seven OEI MD4000 lasers are used only to cut paper: the balance are used for a variety of materials, including plastics.

The business is divided into segments, including its branded Paper Orchid and Stencil Cafe lines. Orders through Paper Orchid and Stencil Cafe are processed the same as any other customer order.

Good relations

Perhaps the most critical relationships for the company are the ones it enjoys with outside design firms. While the company has in-house designers, it is the outside design firms that work in conjunction with the larger companies that drive the plastics-cutting business. “Most of our business is long term,” explains Meiborg. “We tend to work with the same design firms; they get the clients and come back to us for laser cutting.”

Laser Excel also boasts of its ability to provide full capabilities from the start of a project to its finish. As a “complete job shop,” Meiborg points out, in addition to laser work, the company offers screen printing, digital graphics, processing that can involve shrink wrapping or packaging product for customers, and shipping to anywhere in the world.

Room for growth

The company’s newest venture-in which it started extensive engineering work late last year-involves wood inlays and custom designs. Its laser systems have the ability to cut hundreds of varieties of wood, which ultimately form a pattern of colors that can be cut to most any design and incorporated into proudcts for the home furnishings and custom markets. Now, the company is working with a number of carpenters who are selling the idea to their customers. It all began with one of the laser operators “experimenting” with the wood and a laser. So far, it is being well received. “Actually, wood inlay is one of the top search terms that hits our website,” says Meiborg. “We think this is indicative of a growing market.”

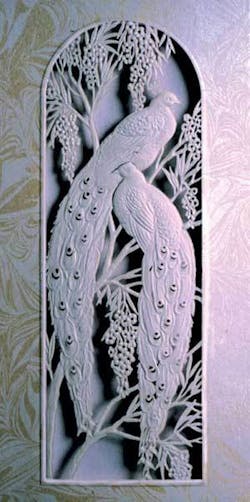

Laser cutting is not only an effective tool, it is also a great design outlet. For the finest of details, smoothest of lines, precision, and accuracy, laser cutting is an unmatched resource. More than 20 multi-head laser cutting systems enable the company to service the many designers using acrylics for displays, awards, and more. Through its Stencil Cafe business, the company offers standard and custom stencils categorized by alphabets & phrases, bakery, home decor, paper crafting, and seasonal.