Laser welding in commercial furniture manufacturing

Expanding into new metal markets with R&D

Luis Ángel Voces Rebordinos and Álvaro Prada Fernández

More Industrial Laser Solutions Articles |

Laser welding in commercial furniture manufacturing Laser-GMA hybrid joining of thick high-strength steels |

Over the past few years, the aesthetic appeal of display furniture design for retail stores has increased exponentially as a consequence of visual merchandising strategies. The quality requirements of metallic components for display furniture, decorative elements, racks or store counters have also increased at the same rate. Today, these elements are considered a key factor in the brand image of trading companies. The increasing competitiveness in commercial furniture manufacturing involves the implementation of new processes with enhanced productivity in order to reduce the manufacturing costs without detriment to the quality requirements.

To fulfill these objectives, Hydracorte, a company with years of expertise in laser cutting of sheet metal, has focused its efforts on implementing and pioneering disk laser welding technology in this industry field as a flexible and productive solution for welding metallic components intended for this commercial sector, an application which, until now, has been served by arc welding processes.

To develop this new business line, Hydracorte is conducting R&D activities in collaboration with the AIMEN Technology Centre to increase the know-how about the laser welding process, improve the technological level of its facilities, and access new industrial markets that require this kind of technology. AIMEN, located in A Coruna, Spain, has dedicated its efforts over the past 40 years toward the development and strengthening of the competitive capacities of companies through R&D activities and technological services.

Hydracorte, founded in 2000, focused its activity on industrial cutting of all kinds of metallic materials using abrasive waterjet technology. After continuous technological evolution, the company has diversified and enhanced its capabilities and assets, both technical and human, mainly with the implementation of other kinds of manufacturing methods like welding, metal forming, punching, milling, or marking. With these methods, Hydracorte can develop the entire fabrication process of commercial metallic furniture, decorative elements, or window display components for worldwide textile stores.

In regard to this technology evolution, laser technology has produced a push in Hydracorte's manufacturing process, giving it a flexible manufacturing system to reduce delivery times and to offer a quicker and more efficient service for all clients in cutting, welding, and metal forming. To develop these activities, Hydracorte has a 6,000 m2 facility, which includes a wide range of high technology machinery for laser cutting, welding, and marking that makes it possible to manufacture parts in the most flexible and economical way, while offering a comprehensive service.

Hydracorte is reportedly the first company in Spain to focus laser technology on the welding of metal components for the commercial sector. This differentiating factor makes the company a pioneer in the implementation of this technology and positions it at the forefront of the global industry in this field.

CO2 laser cutting

Hydracorte currently has three Trumpf CO2 laser cutting systems for sheet metal (mainly carbon steel, stainless steel, and aluminum alloys): a 3 kW TC L3030S model, a TC L3050 model with 5 kW output power, and a TL 5040 model with 7 kW laser output power and a maximum working area of 4000 mm × 2000 mm (Figure 1). These allow cutting from 0.5 mm up to 25 mm in noncoated and galvanized steels, 30 mm in stainless steels, and 20 mm in aluminum alloys, as well as other materials such as brass and titanium. The machinery's high degree of automation, including options like a single laser cutting head for processing all the possible thicknesses, an automatic nozzle changer, an automated sheet loading and unloading system connected with the robotized storage system, increases the productivity in such a way that large batches are not a problem.

In addition, two Trumpf CO2 tube laser cutting machines have recently been installed for processing any profile section (round, square, rectangular, oval, etc.): a TruLaser Tube 5000 model with 2.7 kW output power and a TruLaser Tube 7000 with 3.6 kW laser output power, which allow any type of laser cutting on tubes with up to 10 mm thickness. Profiles with diameters ranging from 10 mm to 250 mm can be machined with this kind of equipment. These machines include an automatic loading system to process 6 m length profiles in a single part and tube seam welding detectors to place the machined contours in the right position.

Disk laser welding

Placing Hydracorte at the forefront in its industry, the company has installed a Trumpf TruLaser Robot 5020 cell (Figure 2), equipped with a TruDisk 4002 4 kW laser disk source with two outputs for optical fibers. Minimum spot diameter on the workpiece and minimum spot size of the beam are 0.2 mm and 0.6 mm, respectively, with a beam quality of 8 mm x mrad and a BEO D70 laser head (with a 200 mm focal length), which offers the possibility of a productive welding service adapted to the highest quality standards for different applications. This cell is equipped with a 6-axis Kuka KR30HA robot, a swivel tilting table, a two station rotary table, and a horizontal rotary axis.

These components make it possible to obtain maximum accuracy, reliability, repeatability, and easy access to the workpiece and maximizes the quality and accuracy advantages already offered by the laser cutting process.

Laser marking

Hydracorte also has a compact Trumpf VectorMark station for laser marking of pieces. This station is capable of marking with high quality onto a wide variety of parts in different sizes, shapes, materials, and all kinds of graphic contents (serial numbers, barcodes, logos, etc.).

Laser influences the manufacturing process

To evaluate the influence (technical and production) of laser welding on the manufacturing process and typical applications, the company initiated the MONACO project to "develop new concepts of auxiliary furniture and decorative components for the sewing industry using laser technology" in collaboration with AIMEN Technology Centre. This project is co-funded by the government of the territory of Galicia, Spain -- the Xunta de Galicia -- where Hydracorte and AIMEN are located, and its Consellería de Economía e Industria. It is also funded by the Fondo Europeo de Desarrollo Regional (FEDER, the European Regional Development Fund) and called "Fomento de la Investigación y de la Innovación Empresarial 2010."

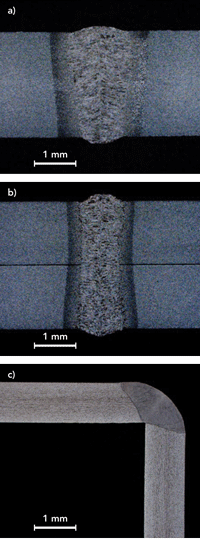

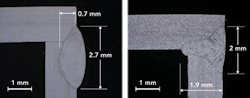

In this project, disk laser welding was evaluated for several joint configurations (butt joint, overlap joint, or corner joint) (Figure 3) and several combinations of metallic materials and thicknesses (the most common combinations in the current manufacturing system), and the results were compared with the previous gas tungsten arc welding (GTAW) (see Table 1).

These tests defined the parameter window of laser processing (laser power, welding speed, focal position, and shielding gas type and flow) in order to obtain good geometric quality, and microstructural, functional, and aesthetically acceptable welds for a wide range of constructive possibilities.

In metallic furniture manufacturing, laser welded butt joints are generally used for profile closure and subcomponent assembly after the previous processes of laser cutting and bending. In this joint configuration, the requirements for joint positioning and adjustment are particularly critical for laser weld quality. For this reason, the gap between sheet edges should be less than 0.15 mm.

Overlap joints also allow the assembly of furniture subcomponents, and this joint configuration is a constructive solution to facilitate the laser welding process and to allow the development of new piece designs that maximize the productive capabilities of laser welding technology. This is because its implementation permits the elimination of butt joints, which facilitates the positioning of the components.

Finally, corner joints are widely used in the manufacture of components for commercial furniture, office or home, for aesthetic and hermetic edges, with the objective of replacing adhesives or mechanical joints that are often subject to corrosion attack. To provide a good aesthetic and surface finish of the joints, laser welding generally uses the conduction mode. With this information, several demonstration furniture components have been developed, such as stock closet hangers and different types of racks or window dressing decorative pieces.

To demonstrate and quantify the potential benefits of laser welding versus conventional arc welding processes, a wide number of samples of both laser and GTAW were produced and were tested by Hydracorte and the AIMEN Technology Centre, first on laser weld specimens and then on demonstrator components (Figure 4). Metallurgical tests and visual observations were carried out.

Laser welding benefits

The main benefits of the laser technology versus the previous welding processes are:

- Higher productivity. Welding speed has increased between 4 to 8 times depending on the application.

- Precise working with exact placing of the energy spot. High repeatability.

- Small focus spot diameter and higher power density on the workpiece with deep penetration welding.

- High weld depth ratio through deep penetration welding.

- Possibility of welding of complicated joint geometries and very different geometrically components.

- Low total heat application (Figure 5) resulting in minor microstructure changes and narrow heat affected zone.

- Generation of high aesthetic quality welds.

- Minimal thermal distortion of the workpiece.

- Low post-weld operation times and costs.

- Higher process flexibility due to large working distance with good accessibility.

- The resistant capacity of storage closet hangers has been increased 5% compared to the previous components welded with conventional welding processes. This is possible while reducing the welding cycle four times.

Laser welding compared to arc welding with filler material

- Need to adjust the previous processes (laser cutting and bending) tolerances.

- Need to make specific welding tools to adapt the manufacturing process of components to the new laser welding process.

- Need more complex and more precise welding tools (Figure 6).

- Ability to develop new innovative piece designs, adapted to higher constructive flexibility that allow laser technology. In this case, cost-effective laser welding demands workpieces designed in a manner that is compatible with laser technology. Proper design and laser weld positioning results in high quality welds that require little or no finishing operations.

With this laser technology, manufacturing small batches and prototypes, which previously represented a great cost, is made possible by the high degree of flexibility provided by laser welding. With this flexible manufacturing system, it is also possible to introduce or adapt new piece designs.

In order to develop this new business line, Hydracorte is currently carrying out different R&D activities in collaboration with the AIMEN Technology Centre related to different laser processes:

- ETNA Project: "Laser Additive Manufacturing of High Added Value Components" led by Hydracorte, which aims to develop an additive manufacturing system by selective laser deposition, which makes viable the industrial production of parts, using and developing technologies and procedures in order to manufacture and/or reconstruct high value-added parts.

- AUTOLAS Project: "Laser robot cell, flexible and easy to use, with an implemented expert system." The main goal of this project is to give a feasible solution to small- and medium-sized enterprises (SMEs), to implement a robotized laser system in their shop floor, with the minimum requirements in terms of money and qualified staff, which are the main barriers to tackling these kinds of installations by these enterprises. The project scope includes the development of an offline system to get the robot program from a 3D CAD file and also develop an expert system to set the laser parameters in an automatic way from the data introduced by an operator through an easy-to-use interface.

Both of them are funded by the Centre for Industrial Technological Development (CTDI) and the Fondo Tecnológico, and also supported by the Ministry of Science and Innovation and the Consellería of Economy and Industry of the Xunta de Galicia through the Galician Innovation Agency (GAIN).

These R&D activities allow the company to increase its know-how about laser technologies, improve the technological level of its facilities, and access new industrial markets that require this kind of technology. In the same way, the activities increase the technological level of Hydracorte's manufacturing system, consolidate its position in the custom metal fabrication equipment industry, mainly for the commercial sector, and increase the portfolio company diversification of products and industries for the coming years. ✺

Luis Ángel Voces Rebordinos ([email protected]) is with Hydracorte S.L., A Coruna, Spain, and Álvaro Prada FernÁndez([email protected]) is with the AIMEN Technology Centre, A Coruna, Spain.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles