High-speed, high-power laser welding

Manipulating optics allows for reduced defects and time

DON BEGNEAUD and RENE DE MOURA

Begneaud Manufacturing has a history of finding unique solutions to industry problems. It was no different when the company discovered the limitations of the focusing characteristics on its laser welding machines, but, as always, it did not accept them as fixed or fact. Rather, it viewed the problem as a starting point—who knows where things can go from here? This mindset is part of a workplace culture that is the norm for the company. By striving for what could be, rather than accepting what "cannot" be, it is able to stretch the realm of possibilities.

In this case, the conversation about different possibilities may have begun with the company, but quickly expanded to include others. The relationships it has forged with various individuals and organizations throughout the entire industry are the foundation of true collaboration.

With the help of outside collaboration, the company has been able to define a new process that changes the way it can manipulate the focused laser beam spot on the workpiece—a method that was not possible with the standard equipment on its lasers. The aim was to produce cleaner weld seams while increasing the positioning tolerance of its 5-axis 3D welding process and reducing weld defect scrap rate, all without sacrificing welding speed. The company derived a custom shielding gas mixture and utilized custom optics that allowed full-power processing at full speed with an elongated focal point, ultimately reducing scrap rate, welding defects, and welding time. Exploration of this new innovation revealed other practical laser welding possibilities and benefits that the company could not have previously imagined.

Background

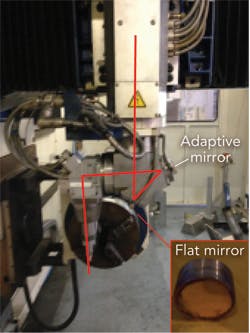

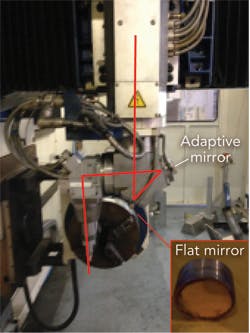

The laser focusing head (FIGURE 1) is from a Trumpf 5-axis Trumatic system with a TLF5000 CO2 laser resonator. This system can be used for cutting as well as welding applications. For welding applications, a standard parabolic focusing mirror with focal length of 200mm is traditionally used to achieve a good penetration depth, even through 1/4in. stainless steel. A standard mirror yields a focused beam caustic that is substantially axis-symmetrical about the z-axis and whose waist section is circular with a diameter of about 0.16 mm, thus yielding an average power density of about 6.3MW/cm2 at full 5kW power.

However, at such high power density, gas plasma formation is significantly more volatile, the welding process becomes very unstable, and the process generates a high scrap rate due to welding defects (porosities, pinholes, undercuts, and a high level of projection spatter). As a consequence, production operators are forced to reduce the desired power down to 2.5kW and cut the power density in half. This results in much better weld quality and reduced welding defect scrap rate; unfortunately, this also causes reduced welding speed compared to the capability offered by the company's 5kW laser asset. This hindrance was the starting point for its innovation.

New setup

The proposed solution changes the gas mixture used for plasma suppression and shielding to a customized mixture of helium, argon, and hydrogen, and also changes the focus characteristics from a small circular focused beam spot on the workpiece to an oblong one with the longitudinal dimension of the focused beam spot parallel to the welding direction. This can be accomplished by replacing the company's standard FL 200 mm parabolic focusing mirror with a new, high-speed high-power (HSHP) mirror. When the standard parabolic focusing mirror is replaced by an HSHP focusing mirror, different focus characteristics are obtained in the z-x vs. z-y vertical planes.

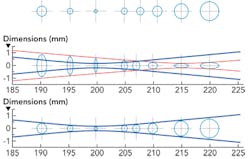

The new HSHP focusing mirror is identical to the standard FL 200 mm parabolic mirror except for a slight change in the profile of the reflecting surface, enabling an oblong focused beam spot. No retrofit is needed on the machine. With increasing power, a small circular focused beam spot yields an increased weld defect scrap rate, whereas elongating the spot proportionally to the commanded laser power maintains a low scrap rate (FIGURE 2).

Experiment

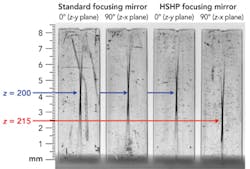

This test was done on slanted Plexiglas to see the difference in beam characteristics when welding at a direction of 90 degrees from one another (P=5kW and V=20m/min). Beam caustics propagate along the vertical z-axis (FIGURE 3): With a standard parabolic mirror, the beam cross-sections remain fairly circular; with a HSHP optic, the beam cross-sections in z-x and z-y planes are different.

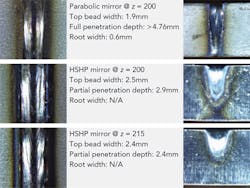

In bead-on-plate welding of 3/16in. stainless steel with He/Ar/H2 mixture shielding gas with 5kW power welding at 2500 mm/min, the high power density of the standard parabolic mirror enables a deeper penetration at the cost of a high weld defect rate (FIGURE 4, top). With the HSHP mirror, enhanced melt efficiency is evidenced by a wider top bead and larger FUZ. For penetration requirements of less than 2.9 mm, the HSHP mirror enables faster speed at equal FUZ width (FIGURE 4, middle). Tested with a 2.4mm penetration requirement, the HSHP optic enabled operation at full welding speed and at full power (FIGURE 4, bottom).

Applications

Developing this technology allows the company to work with clients to find effective solutions for their production needs. Manipulating the optics on the company's machines enables accommodation of various cutting and TIG or MIG welding applications that may have been performed by hand in the past. That flexibility allows the company to manufacture products that meet clients' specific needs for fit and function, pricing, delivery, etc. This results in high-quality projects (FIGURES 5 and 6) with significantly reduced production times over both the short- and long-term project lifetime, as well as substantial savings to the client.

DON BEGNEAUD and RENE DE MOURA are with Begneaud Manufacturing, Lafayette, LA (www.begno.com).