Laser cutting of through vias in quartz

Portland, OR - Quartz is one of the most important materials widely used in the fields of chemical analysis, biotechnology, optoelectronics, micro-optics, and fiber technology. Laser micromachining is a powerful tool for quartz fabrication, with the advantages of no tool wear, high precision, and flexibility. However, quartz presents two major difficulties for laser machining. First of all, it is optically transparent from the visible to near-infrared wavelength range, making it very difficult to process with lasers of these wavelengths. Secondly, because of this weak interaction, high peak power is necessary to initiate laser machining and the associated high pulse energy typically produces a violent interaction that results in chipping and cracking, yielding very rough cuts.

Eolite Lasers recently reported on a new laser glass cutting technique for use with high-strength, chemically tempered glass in the March/April issue of Industrial Laser Solutions ("Precision glass processing with picosecond laser pulses"). In this work, the company demonstrated cutting both internal and external curved features with chip sizes of less than a few microns. It has since expanded this technique to drill taper-free holes with excellent edge quality in quartz.

Process setup and via drilling process

The BoreasFlex fiber laser, operating at 343nm, was utilized to fabricate 1.2mm-diameter through vias in a 0.7mm-thick quartz substrate. The fiber laser can generate pulses ranging from 1 to 190ns at 343nm, and the repetition rate can reach up to 1MHz with a maximum power of 20W. The collimated laser beam is focused to a spot size of about 9μm on the target and moved in a circular path consisting of a number of concentric circles with a galvo scanner. A vertical axis stage continuously moves the focus from the bottom surface to the top surface to complete the cut, as the company describes in the March/April article.

Results

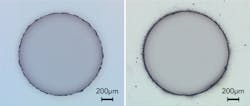

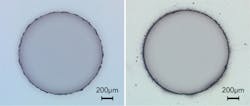

Both the entrance and exit diameters are about the same—1.22mm—indicating a vertical hole wall without significant taper angle (see figure). Also, the edge quality of the hole is excellent, with the chip size on both sides measuring less than 20μm. Results show that a UV nanosecond laser provides a very good solution for fabrication of small vias in quartz. The chip size is well controlled by careful choice of laser parameters.

The company found that the process speed for processing these vias equates to about 0.12mm/s or approximately 30s per via. This cutting rate is significantly slower than that achieved in prior glass work, and the company speculated that this is primarily due to the higher strength and fracture toughness of quartz compared to glass—more energy is required to remove the material. With further process and beam positioning optimization, the company plans to reduce process time to less than 10s per via with similar cut quality as reported here.

Conclusion

The company has extended its previously reported glass cutting technique to include cutting of vias in quartz with no wall taper and chip size on both entrance and exit of less than 20μm, with about a 30s cycle time for a 1.2mm-diameter hole. It expects this process to find application in several industrial areas, including microfluidics and microelectromechanical systems (MEMS).