Microfabrication feast

Japan plays host to 5th International Symposium on Laser Precision Microfabrication

LPM 2004 was organized by JLPS—Japan Laser Processing Society, RIKEN—The Institute of Physical and Chemical Research, AIST—National Institute of Advanced Industrial Science and Technology, and SPIE—The International Society for Optical Engineering. Held May 11-14, LPM 2004 was the 5th International Symposium on Laser Precision Microfabrication, after the 1st LPM 2000 (Omiya, Japan), 2nd LPM 2001 (Singapore), 3rd LPM 2002 (Osaka, Japan), and 4th LPM 2003 (Munich Germany). About 260 attendants—about 67% from Japan, 17% from Europe and Russia, 10% from North America and 6% from Asia outside Japan—enjoyed the forum held in the Nara-Ken New Public Hall in the center of Nara National Park (famous for its beauty and old historical arts and shrines) for discussion of fundamental aspects of laser-material interaction, the state of the art of laser material processing, and topics for the next generation by collaboration among fundamental scientists, end users and laser manufacturers.

The technical sessions of LPM 2004 consisted of 29 oral sessions, a poster session and a short poster presentation session. Except for the plenary session, the rest of the 28 oral sessions were held in parallel throughout the four-day event. The second day of the conference was the busiest because the oral sessions were held in three parallel sessions and a Noh Play, a traditional old Japanese drama art and banquet as garden party, were held as special events for LPM 2004 that evening.

According to the symposium program, there were 176 contributed papers in all, including 25 invited papers and 54 poster papers. The regional shares for the paper contribution were about 45% from Japan, 26% from Europe and Russia, 15% from Asia outside Japan, and 14% from North America. The numbers of contributed papers by nations were Japan-79, Germany-24, USA-22, Korea-8, Singapore-7, China-8, Russia-5, Switzerland-5, UK-4, France-3, and the other 10 nations-13.

Among the above 29 oral sessions, four oral sessions were allocated for the Special Session 1—Laser microfabrication of glass ceramic and novel applications, two oral sessions for the Joint Session on ultrafast laser processing of glass/ceramics, and three oral sessions for the Special Session 2—Advances of high-power single-mode fiber lasers. These areas were highlighted as those in which many attendees had interest.

The plenary session held at Noh hall included three invited talks from Japan, Germany, and USA after the opening remarks by Symposium Chair, Isamu Miyamoto (Osaka University).

The topics covered by the invited plenary speakers were three-dimensional laser microfabrication using femtosecond laser by Koji Sugioka, RIKEN, Japan; micromachining with micro-, pico-, or femtosecond pulses: European results and applications by Friedrich Dausinger, Universitat Stuttgart, IFSW, Germany; and an overview on laser microfabrication from a commercial perspective by C. Paul Christensen, Potomac Photonics, USA. Sugioka stressed that laser processing opens new avenues for 3-D micro- and nano-fabrication. Dausinger pointed out that high-repetition-rate picosecond pulses of up to 100W will provide real industrial applications for processing metallic materials of technical importance with increased process efficiency. Christensen emphasized that the pervasive drive toward miniaturization seen in the wide range of electronic and micromechanical devices offers many opportunities for laser microfabrication tools and processes for an increasing number of commercial applications.

In the Special Session 1, a tutorial presentation entitled "Laser properties by glassy materials: How to marry material properties and laser parameters to achieve desired results," was given by Kathleen Richardson, University of Central Florida, USA, and Henry Helvajian, The Aerospace Corporation, USA. This tutorial set the tone for the Special Session 1, summarizing, from the optical material science perspective, the fundamental structure and properties of glassy materials that influence response under laser illumination and presenting guidelines suggesting how laser-machining specialists can capitalize on intrinsic material parameters and/or tailoring materials physical properties, as well as laser irradiation parameters, to achieve desired post-processing results. Advances from the material-side approach presented at the Special Session 1, such as on laser machinable glass and photostructurable glass ceramic materials, seem to have a promising future for expanding laser applications with improved process speed and efficiency.

In the Special Session 2, high-power single-mode fiber lasers were highlighted toward new avenues to real world applications of ultrafast fiber lasers, new opportunities in precision microfabrication, and so on. Among the several excellent invited talks given at Special Session 2 was one by Stuart Woods, SPI, Southampton Photonics, UK, on "Tailoring fiber laser specifications for applications from micro-machining (100W) to cutting (1kW)." Andreas Tünnermann, Fraunhofer Institute, Germany, and Stefan Nolte, Univ. of Jena, Germany, presented properties of high-power ultrafast fiber laser systems and showed observed machining quality improvement in material processing of metals. Valentin Gapontsev, IPG Laser GmbH, Germany, presented on "Fiber laser—New opportunities in precision microfabrication," and Isamu Miyamoto, Osaka University, Japan, presented welding and cutting experimental study results using single-mode Yb-doped fiber lasers with maximum single-mode output power to 200W.

With 190 W at the workpiece of 0.1 mm thickness SUS304 sheet, cutting speed of 2000mm/s and with 190 W at the workpiece of 0.3 mm thickness SUS304 sheets, overlap welding speed of 2000mm/s have so far been obtained.

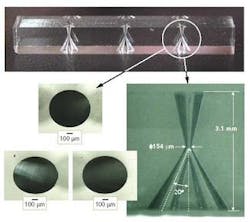

Among the many ordinary technical sessions with a lot of interesting topics, the Session No.27, Ultrafast laser ablation and treatment, and Session No.28, Ultrafast laser microstructuring, seem to have presented the most profound implications and hints for future industrial applications of laser precision microfabrication. Alan Arai et al of IMRA America Inc. presented on "Laser ablation threshold and etch rate comparison between the ultrafast Yb fiber-laser-based FCPA lasers and a Ti:sapphire laser for various materials," and suggested the potential advantages of ultrafast Yb fiber-laser-based FCPA lasers. Akihiko Nishimura et al. of Japan Atomic Energy Research Institute presented on "Ablation of work hardening layers against stress corrosion cracking of stainless steel by repetitive femtosecond laser pulses," and showed that femotosecond laser ablation can successfully remove work hardening layers without serious thermal damage to sample inside. This new technology looks promising for repairing the boiling water reactor core shrouds in the near future to prevent the stress corrosion cracking (SCC). Takayuki Nakaya et al. of Namiki Precision Jewels Co., Ltd. presented on "Fabrication of precision microholes and structures with smooth surfaces by high repetition rate femtosecond laser," and showed that a combination of a high-repetition rate femtosecond laser and chemical etching can provide micro holes with smooth surfaces having mean roughness Ra of 4.5 nm, comparable to a polishing surface of a glass, and is sufficient for almost any applications. Using this technique, they have produced a Y branch hole, a taper hole, a micro die, and more (see Figure 1).

Furthermore, Andreas Ostendorf et al. of Laser Zentrum Hanover e. V., Germany, presented very important practical subjects on "Short and ultrafast laser pulses: Applications driven comparison of source types." The high potential of innovative picosecond-laser beam sources was highlighted against sophisticated femtosecond laser sources for processing of metallic materials and more.

There were many other interesting and important papers in LPM 2004, such as "Applications of laser direct-write technique for embedding electronic and micropower combination," by Alberto Pique, Naval Research Laboratory, USA; "Advanced laser processing for integrated biophotonics on a chip," by Peter Herman of University of Toronto, Canada; and "Current status and future prospects of laser stereolithography," by T. Hagiwara, CMET Inc. Japan. Interested readers are advised to refer to the LPM 2004 website and conference proceedings for further information. General information on LPM 2004 is available at the website:http://www.jlps.gr.jp/lpm/lpm2004/index.html. The conference proceedings will be published from SPIE hopefully within this year. The 6th International Symposium on Laser Precision Microfabrication—Science and Applications will be held April 4 through 7, 2005, in Colonial Williamsburg, VA.

Kunihiko Washio is with Paradigm Laser Research Limited, Japan. He can be reached at [email protected].