Cutting glass

Mukilteo, WA — Cutting of glass with CO2 lasers has always been a tricky problem due to the thermal expansion characteristics of the glass compositions to be cut and the thickness of the glass. Stress from localized heating effects typically resulted in fracturing along the cut edge. For glass between 1 and 10 mm thick, laser cutting becomes a two-step process of scribing and snapping.

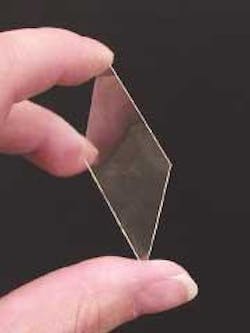

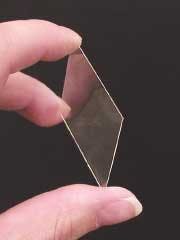

Today products ranging from microscope slides to covers for flat-panel displays are made from thin glass substrates. These glass sheets, measuring only 30-600 microns in thickness, are easily cut with CO2 lasers and the cut edge has the same quality as seen in other laser cutting applications.

Shown is a 150 mm thick section of glass that was cut using 100 watts of power at a speed of 550 inches/minute. The laser was gated with 1.2ms pulses at a frequency of 750 Hz, using 10 PSI of air as the assist gas.

This work was done at Synrad, www.synrad.com.