World's first aluminum tailored blank

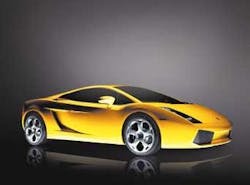

Duffel, Belgium—In case you should happen to see a Lamborghini Gallardo cruising down the Interstate, and it certainly will get your attention, admire it's clean Italian designed lines. And, while you do, be advised that this handsome vehicle made by an Audi division also sports the world's first laser-welded aluminum blank used in the Gallardo's front wheel arch. Production using this blanked part started on this model in the spring of 2003, and through the end of the year 1200 pieces had been supplied.

Welded at the Corrus Aluminum Rolled Products plant located here, the aluminum blank was developed at the Corrus R&D center in Ijmuiden, The Netherlands (see ILS March 2001). These two organizations along with Audi decided to bring to market a product that combines the weight advantage of aluminum with the benefits of tailored blank technology. Corrus laser welds two different grades (5000 and 6000 series) and thicknesses of aluminum to provide optimum strength while using the least amount of material possible for specific points on a vehicle.

Today steel welded tailored blanks account for more than 15 percent of the average vehicle body structure on high-volume models. Corrus anticipates that this will rise to 25 to 30 percent on all steel body-in-white car production this decade. Aluminum, however, is more difficult to weld, restricting its use as a welded blank, so Corrus invested in the laser-welding center in Ijmuiden in 2001. The result, a robust process with the consistently high-quality weld seam required to move from prototypes to series production. And now that investment is beginning to pay off.

Commenting on the cooperative relationship with Audi, Johan Ameel, director of Corrus Aluminum Rolled Products, says, "We are confident that Audi and other vehicle manufacturers will now maximize the full weight advantages of combining aluminum with tailored blank welding technology to help further reduce vehicle body and chassis component weight on future aluminum models or with specific automotive applications."

Corrus also supplies aluminum coil and sheet for all outer and inner panels of the Lamborghini Gallardo as well as aluminum body and structural parts for Audi, BMW, Daimler Chrysler, Peugeot, Volkswagen, and Volvo.