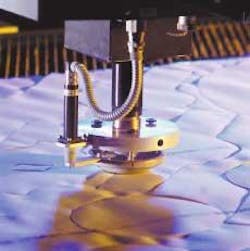

Laser cuts multilayer textiles

Laser cutting of multilayered textiles, such as fabric for automotive airbags, has evolved significantly since an article in the March 2001 issue of this magazine discussed the topic. This parallels the increased demand for automotive airbags as new car designs include front, side, and curtain airbag assemblies. The advantages of multilayer cutting are quite clear. Simultaneous cutting of multiple layers, compared to single-layer cutting, yields increased volumes and decreased costs.

Multilayer laser cutting of technical textiles can be quite tricky and producing successful results is more difficult to effect than one might think. Experience, innovation, and sound technology are the keys to success. Over the last ten years, the process technology has evolved at Schuler Held Lasertechnik (Dietzenbach, Germany), and today, it is the state of the art in mass production of laser cutting of airbag material.

When Schuler Held was approached in 1993 to build a laser cutting machine for airbags, it addressed the known challenges first, including discoloration, the improper fusing together of laser-cut cloth layers, and the possibility of increasing the number of layers being cut simultaneously.

Some efforts at multilayered cutting in the past were not completely satisfactory. Though previous processes could cut multilayers, satisfactory separation of the layers was not always achieved. Paper separators were burned by the laser, leaving the cloth edges discolored.

Laser cutting of textiles containing plastic fibers has the advantage of melting the individual fibers at the cutting edge, which prevents the fabric from unraveling. However, the challenge for laser cutting is to prevent the sheets from welding together.

Together with its customers, Schuler Held developed the process technology of laser cutting up to 25 layers of fabric and leaving them easily separated and clean.

Previously, paper was used as a separator between the individual layers, but it was proved in various tests that PET foil is the most suitable material for separation. It prevents unraveling of the fibers at the cutting edge and at the same time ensures a finished edge. During thermal cutting (laser) of the fabric and the separator foil, the melted thermoplastic diffuses into the fabric, creating a better melted and unraveled edge, compared to single-layer cut material. Coating of the airbag fabric with silicone does not influence the cutting process and the quality of the cutting edge.

As the process of laser-cutting airbag material evolved, various special devices, technologies, and features were developed at Schuler Held for increasing productivity, for performing high-quality cutting for high-volume production, and for ensuring production security. One example of this is an automatic focus positioning/distance control device that enables the laser cutter to process different heights of fabric layers, yet maintain the same cutting edge quality. Furthermore, either compressed air or nitrogen may be substituted for the cutting gas, depending on the materials to be cut. Other special devices suited to meet the individual requirements of a fabric can be integrated into the systems. This might include an ironing device to remove air between the different fabric layers, a suction box with drawers for easy cleaning of the fabric, or rotating brushes to remove the waste from the cutting grid.

When using a 3kW CO2 high-power laser, it is possible to achieve cutting speeds of up to 20 m/min with approximately 20 layers of fabric. The cutting speed can be increased and the laser power can be reduced, respectively, if the number of layers is reduced (see the diagram). The final airbag cutting system design depends on the individual customer's requirements, such as the material to be processed, the yearly production, and the available floor space in the factory. These individual needs typically can be accommodated by a standardized modular system of machine components. Cutting tables already in use in these fabric cutting systems range from 4 × 2 m to 6 × 2.5 m to 8 × 3 m.

The most recent evolution in high-speed, multilayer cutting is a machine having a 7 × 2.5 m cutting table capable of realizing travel speeds up to 135 m/min with an acceleration of 1.5g. This cutting system is in production at UTT (Krumbach, Germany), currently producing up to 1000 airbags per hour cut out of 20 layers of silicone-coated fabric (PA66).

Today, laser cutting of airbags is a precise, high-volume operation, where improved production techniques are decreasing the price of airbags. Systems can now produce up to 1000 airbags per hour, a tenfold increase when compared to expected output five years ago.

There are many other applications for multilayer cutting today. In addition to airbag fabrics, it is also possible to cut other materials such as cotton-nylon fabric, woven aramide fibers, felt sheets, plastic/artificial leather parts, and filter cloth. The laser beam is the most flexible tool for all these cutting applications.

Ralf Möller ([email protected]) is with Schuler Held Laser Technik (Dietzenbach, Germany) and David Guastaferri ([email protected]) is with Schuler Inc., (Canton, MI).

production cutting

The most common methods currently in use for cutting airbag material include the following:

- A continuous flow of material, from 1–6 layers deep, is fed into a cutting machine where it is cut to shape. The fabric and the airbag itself, respectively, are cut without prior cutting the different sheets to length. Simultaneously, the material is fed through the machine. The advantage of this process is the minimum quantity of waste. The disadvantage is the low output of such a machine configuration.

- In another processing method, airbag fabric is unwound from the coil onto the cutting table for multilayer cutting of up to 25 layers. Prior to cutting to shape, lengthwise cuts of individual stacks is done with a mechanical knife. The pile of approximately 25 layers is fed into the laser cutting machine where each individual stack is cut, using high laser power. The advantage is very high productivity and output. The disadvantage can be higher waste depending, on the nesting of the airbags on the fabric in connection with a 90° mechanical knife cut. This, however, can be minimized by means of contour cutting devices using low laser power. Due to this contour cutting device it is possible to cut each layer of fabric so that only a minimum of waste is produced.