Expanding the customer base

Since its 1984 founding in a modest 8000-square-foot leased building, BMP Metals Inc. (Brampton, Ontario) has earned a reputation as an integrated precision manufacturer dedicated to hiring quality people, providing these employees with ongoing training, and investing in the best capital equipment for the work it produces. BMP also is recognized as a premier design problem solver for its customers.

This philosophy has paid handsome dividends for BMP. Today, the company has more than 200,000 square feet of fabrication and machining manufacturing capacity in four different locations. By 2001, the company's growth had resulted in a large portion of its business directed toward the telecommunications industry. With the downturn in telecommunications, diversification to other industries became a very important goal for BMP. The company also knew that procuring the most flexible sheet metal fabrication equipment was crucial to achieve its diversification.

To boost its production capacity, in October 2002 BMP chose the Finn-Power LPE (www.finnpower.com, Schaumburg, IL) high-precision, laser/punch-combination flexible manufacturing cell. "When the LPE arrived, we called it our Star Wars machine because it did so many things," explains Robert Bedard, president. "It can do laser cutting, punching, nibbling, upforming, marking, tapping, bending, sorting, and stacking—all unattended, all in a single setup."

Optimum use of this laser system means a fabricator can use the turret punch press where it is easier or faster and the laser where it is most effective. The LPE enables the user to look at the parts, the materials, the part design elements, the time, and the overall cost of the parts to determine the optimum process.

One of the benefits Bedard saw in the LPE was a reduction of piece part costs resulting from faster punching time, a reduction in direct labor assigned to setup and punching, and a reduction in the number of manual operations required. Another benefit was utilization of full sheets while eliminating the need to shear to the size of the blanks being processed. A third benefit can be increased machine utilization. If a loading system is purchased with the LPE, unmanned operation can be achieved from load, punch, upform, laser cut, and unload and sorting of parts in one machine.

The punching part of the system consists of a 22-ton turret punch press that combines electrical servo technology with mechanical power transmission. The net result is a system with both flexibility and amazing accuracy. Other features include excellent forming capabilities—16mm high with no die interference; servo system for precise accuracy; low-energy consumption; auto-index, Multi-Tool®, programmable clamp settings; and brush tables.

Other features include:

- High-pressure cutting with a Rofin Sinar Triagon 2.5 kW CO2 laser with 25 Bar assist gas pressure maximum. Higher pressures allow for cutting materials such as stainless steel and aluminum with optimum speed and edge quality.

- An oil-free pump and turbine design that eliminates expensive and time-consuming repairs.

- Excellent energy consumption in comparison with other HF-excited lasers. The savings cost can be up to 40%.

- A laser capacity of 8mm cold rolled steel and stainless steel and 6mm aluminum.

- The ability to change the focal length lens in seconds using a cartridge technique. No tools are required. The cartridges are available in 3.75 in., 5 in., and 7.5 in.

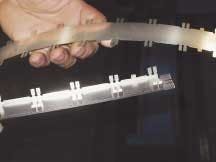

- Integration of the laser and the punch accomplished with the part piece flowing from the turret punch press to the laser without the release of the clamps. The flow of material is from the load side to the unload side, eliminating the time-consuming method of loading and unloading from the same side.

In addition, the O-frame of the turret punch press is separate from the laser, assuring that no vibration will be transferred to the laser. This provides added reliability and uptime of the system.

BMP's relationship with Finn-Power began several years ago with the purchase of the Express (turret punch press with load/unload) and then the Shear Genius (punch/shear combination). Bedard estimates that his company's increase in productivity rose 40% to 100% with the Express and 200% to 300% with the Shear Genius.

"Bringing the laser/punch into the picture helped our people make the transition into laser technology," says Bedard. "About 95% of our parts that we put on the LPE require both the laser and the punch. We prepunch the starting holes to avoid splatter. The LPE gives 100% good parts. We also have been using the upforming feature to a greater degree."

According to Bedard, BMP has generated new business in the medical arena, specifically the MRI carts that utilize a great deal of sheet metal. "We've also increased our business in the industrial console and consumer products industries, as well as high-security enclosures," explains Bedard. "In addition, the telecommunications world has kept us quite busy. A recently announced joint program in India between Nokia and Nortel worth $800 million will also mean more business for us."

BMP is running many different types of metal—stainless, aluminum, and steel—in various thicknesses on the combination machine. "I am actually very surprised to see the wide variations in gauges," says Bedard. "We also are burning some high-strength alloy steel that would be difficult to punch.

"The LPE opens whole new avenues to us in terms of flexibility and capacity, where we are not saying 'no' or 'maybe' to our customers," contends Bedard. "It is a positive move, especially when you consider what we are going through now ... with many different metal types, gauges, and alloys. It gives us confidence. If the customer shows us a new part, we are winning many new contracts because we can say 'yes' more often than 'no.' We have a much better understanding of what our machines can do, and the laser/turret punch system has broadened our range of customers tremendously. It has opened many different doors for us."

Article provided by Finn-Power.