Innovative Glass Microprocessing

During the recent telecom boom/bubble, many photonic companies formed to address the apparent needs of the industry. However, with the bursting of the bubble, these companies have to cope with the current business environment where orders and venture capital are scarce or nonexistent. Here we profile Translume, a startup company that evolved its innovative laser processing technology to meet market needs in the post telecom bubble environment.

Translume (www.translume.com) was formed in 2001 with funding by Ardesta (Ann Arbor, MI) to address the needs of the telecommunications industry. Philippe Bado, a pioneer of ultrafast laser processing, has led this new venture since its inception. Femtosecond lasers are well known for precise ablation of materials with insignificant heat effects.[1,2] Translume's primary technology is the patented femtoWrite™ process that uses femtosecond lasers to create nanostructural changes in transparent materials affecting the refractive index. The change in refractive index is spatially localized and controlled three-dimensionally. Various optical devices covering the range from simple straight waveguides to a much more sophisticated array of interferometric devices can then be fabricated. The process can be automated and controlled precisely, providing a higher order of flexibility to users for complex and multilayered designs compared to conventional lithographic techniques. Hence rapid prototyping of micro-optical and microfluidic components can be carried out. Figure 1 illustrates the process 3D capability using a helical waveguide as a compact optical delay.

The commercial demand for such a technology initially was driven exclusively by the telecommunications industry. With the recent adverse business environment, Translume had to broaden the appeal of its capabilities to other fields. Additional technologies (femtoTrim™ and femtoEtch™) were developed that complemented Translume's femtoWrite™ process. FemtoWeld™, a new process, also is being developed.

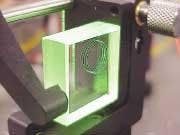

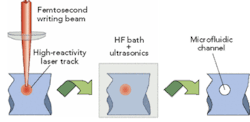

FemtoTrim increases the precision of the femtoWrite process with real-time monitoring and device tuning. FemtoEtch uses the femtosecond laser nonlinear capabilities to sensitize glass for etching instead of ablating the glass.[3] It is a more flexible method than UV lasers that require UV-sensitive glass for photosensitization (see www.mikroglas.com). This "micromachining" method relies on the nonlinear laser modification of the properties of the glass such that the etching rate is enhanced by several orders of magnitude compared to the untreated material. This hybrid micromachining method for transparent materials has no heat effects, as the material is etched away rather than ablated (see Figure 2).[4] With capabilities far surpassing conventional laser ablation, complex 3D microfeatures can be manufactured. FemtoWeld enables annealing or welding of glass substrates and is currently under development.

With this suite of glass microprocessing capabilities, Translume has developed a femtosecond laser micromachining glass foundry. The processing platform is able to ablate glass, induce permanent refractive index changes in glass, change the chemical reactivity of glass, and anneal the substrate. These capabilities enable the development and manufacturing of innovative microdevices that address needs in the aerospace, defense, and biomedical industries as well as telecommunications.

Translume's enabling technologies allow the development of new and improved devices for the marketplace. Although such devices have been developed or are currently under development, their success in terms of volume manufacturing will have to await market acceptance. However, the potential of the enabling technologies is undeniable. Some examples of recent promising developments are described below.

In the micro-optics area, Translume is working with SiMMtec (www. simm-tec.com), a diode array manufacturer, to develop a flexible micro-optics diode beam conditioning device in place of the traditional microlenses. The SiMMtec array uses v-grooves in a silicon submount to precisely place diode bars. The output from each diode bar is at 35 degrees to the horizontal. Using femtoEtch, a micromirror array can be fabricated and mounted on the diode array, turning the output to normal (Figure 3). The device is 1 cm wide by 2 cm long and incorporates 10 mirrors. Similarly, a micro-optics array can be developed to turn and shape the beam for optimal applications. The technology provides flexible fabrication at relatively low unit cost. Currently used technology requires the design of microlenses, fiber pulling from a shaped preform, and sectioning into microlenses. Any change in the beam profile requires a new lens design and pulling a new batch of lenses at a substantial cost.

Using femtoWrite and femtoEtch, sensors can be developed that integrate microfluidics and sensing functions. The prototype device shown in Figure 4 incorporates microchannels and waveguides in a single glass block for sample flow and sensing. Such integrated sensors are compact, extremely robust, and potentially low in cost; hence, a wide range of sensing needs in lubricant and cooling fluid monitoring in addition to biological or chemical sensing can be addressed. Translume is currently working on government contracts to develop integrated sensors that can monitor the quality of lubricant fluids and biological contamination.

In the field of photonic signal control, Translume is working with aerospace and telecommunications companies to develop prototypes that incorporate waveguides and fiber-coupling improvements using femtoWrite and femtoTrim.

Glass is a material that has many desirable properties (inertness, transparency, etc.) and is widely used in industry today. However, conventional and direct laser processing of glass is limited by the very properties that make glass so desirable. The laser-based processing technology discussed here is unique and enabling, in that applications and required processing that were impossible or difficult with previous processing technologies are now feasible at relatively low cost. Translume's glass processing technologies open new applications for glass. Custom micro-optics for laser beam conditioning will be available at low cost in small volumes; lower-cost and higher-performance laser-based sensors will be available for monitoring of lubricants and biocontaminants; more flexible switching photonic circuits for both telecommunications and fiber-optic controlled equipment can be fabricated.

Keng H. Leong is a contributing editor (technology) for ILS and chief technical officer of SiMMtec (Allison Park, PA), a diode array manufacturer.

References

- Leong,K.H., A.A. Said, and R. L. Maynard (2001): Femtosecond micromachining of electro-optic components, 51st Electronic Components & Technology Conference, May 29-June 1, Lake Buena Vista, Florida.

- K.H. Leong (2000): Drilling with Lasers, Industrial Laser Solutions, September, p. 39-46.

- A. Marcinkevicius, et al. (2001): "Femtosecond laser-assisted three-dimensional microfabrication in silica," Opt. Lett. , Vol. 26, p. 277.

- Y. Bellouard, et al. (2004): "Fabrication of high-aspect ratio, micro-fluidic channels and tunnels using femtosecond laser pulses and chemical etching," Optics Express, Vol. 12, p. 2120.