Jaguar cuts costs

Coventry, England - Jaguar Cars uses laser sintering technology at its Whitley Engineering Centre to speed up the development of new luxury vehicles. Laser sintering builds plastic parts directly from CAD models, eliminating the expense of producing mould tools. Systems from EOS GmbH create prototype trim, engine parts, and production aids from polyamide powder in a process that fuses the powder layer by layer into their respective shapes.

The resulting components are robust enough to be used on test vehicles running around the track, allowing more data to be collected early in the development process. Errors can therefore be avoided before they cause high costs.

As an example, in the past, hundreds of thousands of dollars would have been invested in hard tooling the manufacture of a new V8 air intake manifold. Following every design change, it would have cost thousands of dollars to alter the tool; a process that would take several weeks each time. If the changes were substantial, a completely new tool might be needed. With laser sintering, the production of tools becomes obsolete. As a consequence, Jaguar saves time and costs.

The machines from EOS produced two design iterations of the manifold. Seventeen were subsequently built in polyamide for less than $1800 each. The lead-time was one and a half days per manifold, halving the time for development from one year to six months. Jaguar made an enormous financial saving alone for this component.

The bumper section (see Figure 1) of the XJ saloon was built in two pieces by laser sintering, helping to visualize the assembly of key parts such as the exhaust pipe and tow eye fixing, aesthetics that could be evaluated before progressing to hard tooling.

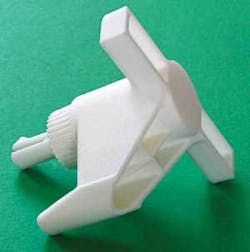

An interesting component (see Figure 2) is a complex plastic assembly aid that assists operators working on the new XK coupe and convertible to position the window lift mechanisms during build. The manufacturing plant required a stock of 3000 of these parts, which remain on the vehicle throughout the build process. By August last year, around half of the parts required had been produced as fill-in jobs, without the need to invest in expensive plastic injection mould tooling.

Jaguar expects to see rapid prototyping quickly develop into rapid manufacturing processes, initially capable of satisfying niche requirements. In the more distant future it is possible that today’s processes hold the key to the next generation of volume production technologies. Laser sintering has a high potential: the technology helps companies such as Jaguar to eliminate design constraints, and tooling and inventory overheads.

EOS GmbH, Krailling, Germany, manufactures laser sintering equipment. The systems used in the above applications were provided by EOS Ltd., Warwick, England.