Laser beam plus three arcs

Wels-Thalheim, Germany-Two high-performance welding processes complement each other to benefit companies involved in shipbuilding and the construction of containers, pipelines, and rail vehicles. R&D experts at Fronius have developed an innovative solution by combining two tried and tested processes, the LaserHybrid and digital TimeTwin Tandem.

When welding thick sheet steel, running a laser beam with three arcs produces a synergy effect. The deposition rate and thus productivity increase significantly. Users also benefit from savings in time, investment, and weld pool support, for example. Other important advantages are greater resistance and improved appearance.

Welders working in shipbuilding, machinery, plant, container, pipeline, and rail vehicle construction often have to join metal sheets that are between 6 and 10 mm thick. In the global market, quality criteria and economic advantages matter. The intelligent combination of laser MIG/MAG + tandem hybrid welding combines the benefits of several processes.

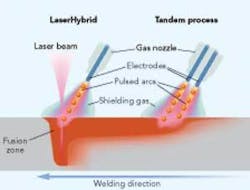

Previously, joining specialists had to choose between high welding speed and good gap bridgeability. Now they can have both. A preliminary LaserHybrid process with one arc creates a very hot liquid zone with a large-weld-depth-to-small-seam-width ratio. This creates the conditions for a perfect root seam. The TimeTwin process, which follows immediately, adds the characteristically high deposition rate. Depending on the type of welding-single layer or several layers-it creates the root cover.

In addition to the laser beam, there are three active arcs. They melt in two pools located one behind the other. Alternatively, the TimeTwin process can work with the laser to melt in a single pool.

Depending on the application, this modular and flexible process can also be used just with a laser or one or two arcs. This allows sheets of varying thicknesses, made of high-alloy or fine-grained structural steel, to be joined in two processes but using one tool or in one welding cell. A higher quality and visually more attractive “soft” material transfer produces better results, because the arc pressure is spread across two or three arcs. Users profit primarily from the increased productivity and lower investment costs compared with conventional processes. In addition, the wider range of applications provides extra flexibility.