The strategy to survive

Laser welding is just one part of this company’s capabilities

Martien H.H. Van Dijk

In addition to the need to address day-to-day problems, company management must also have a strategic plan. Companies that want to be successful over the long term need to adapt themselves to changes in the market. Nijman Arentsen is an example of such a company.

This privately owned company is located in the eastern part of the Netherlands in the small town of Varsseveld. Traditionally this is an agricultural area, so in 1971 Mr. Nijman, father of the current owner, and his partner Mr. Arentsen started a company to make equipment for the local farmers. They started in an old house in the center of the city, and today the company occupies a 130,000-sq. ft. factory on an industrial estate on the north side of the city. In October of 2001 a fire destroyed two of the main production halls. According to Eric Nijman, the son of one of the company founders and present owner, this gave the company the opportunity to reconstruct the layout of that part of the factory for better logistics.

Over the years the company has grown using its know how in steel cutting and welding. Where originally the company mainly used mild steel, today only 10 percent of its product is made from mild steel and 90 percent is made from stainless steel.

The company has also broadened its customer base. It still makes components for the agriculture applications; however this is only a minor part of the yearly turnover. The company now serves Dutch customers and customers from all over Europe and even from the U.S. Walking through the production halls one may see stainless-steel furniture for kitchens and bathrooms and also equipment used in the microelectronics industry. One company strategy is to make complete products designed by clients. This also includes the mechanical and electrical assembling of production lines.

On the other hand the company tries to make the production man independent. This means automation but may also include redesign for less critical production. The company has a number of highly skilled operators whose task is to set up new production and processes and to make one-of-a-kind products. However the main part of the production is done by trained operators who may be temporary employees.

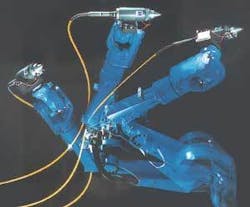

In the early 1980s the company introduced the first robot manipulator for MIG and TIG welding. Now the company has several MIG/TIG robot cells. Ten years ago the first CO2 laser on a combination laser/punch was introduced. This system has been replaced by four other laser systems. In 2004 the company introduced laser welding using a TRUMPF Nd:YAG laser with fiber delivery. The laser source stands in the corner of the hall with welding done in a robot cell. Parts to be welded are mounted and dismounted outside the cell on a rotary table, so as to minimize the production time lost while changing parts.

A half a year after the introduction of laser welding the company installed a second cell equipped with a robot for laser welding. The laser has four fiberoptic output adapters. But, because most products are seam welded with a meter or more welding length, the work cells have to wait for one another, so the laser source is the bottleneck. An effort is now being made to eliminate the bottleneck by using more automated conventional welding.

According to Eric Nijman laser welding is superior in quality and speed. He showed a box-like product that was originally made by cutting, bending, and welding that needed some straightening after bending and after welding. Now the bending is eliminated by welding the product together using separate parts for the sidewalls. By so doing the need for straightening is almost eliminated. Because the weld needs to be leak tight, the company designed a simple leak test unit that is used by the laser operator.

Laser welding allows weld geometries that are not possible by other means. Because the heat input per weld length is minimum, there is less need for heat sinks, so welding fixtures, all made in-house, are lighter and cheaper. However Eric Nijman challenges his engineers to improve the capabilities of the other welding technologies to get the most effective production solution. He doesn’t want the company to be a job shop. The strength of the company is that they can give the customer the optimum solution for welding of the product. But as mentioned before, the company goes beyond just cutting and welding of steel-not only in designing in cooperation with the customer but also in fully assembling equipment.

It is Eric Nijman’s opinion that selection of the proper equipment is crucial. When introducing a new technology into the company they need to select a supplier that can offer service on the equipment and also process support. Training of operators is one of the keys to success. Nijman-Arentsen selected TRUMPF as a supplier for the laser welding equipment because this company was able to give full support. It is Eric Nijman’s experience that shortly after the introduction of a new technology highly skilled and motivated employees have a good understanding and know how of the technology-in many cases even better than most of the application engineers of the equipment manufacturers. This means that, during the selection of a second production unit for the same technology, the decision will be mainly based on price and service.