Rocking the cutting world

This innovative approach aims to expand the laser cutting market

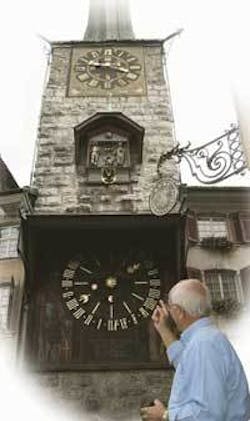

I’m trying to make the 1467 astronomical clock on the tower outside my hotel in Solothurn, Switzerland, move faster. It’s still 26 days before Bystronic, which has invited selected journalists to this 13th century Baroque town, will unveil publicly one of the best-kept secrets in the industrial laser community, and I am anxious to write about what I perceive to be both a technological and marketing milestone.

Just up the road at the company’s Niederonz headquarters I have been given an advance showing of ByVention, which Bystronic describes as laser cutting redefined. It’s a dramatic introduction, replete with rock music, fog machine, multi-colored lights, and dramatic narration. Company CEO Ferdie Töngi spoke of the results of a company-conducted market study, which says that 80 percent of all sheet metal parts for laser cutting were ≤ 8mm thick and 80 percent were ≤ 300mm in size. So the company set out to create a new laser cutting system because it believes there are no ideal machines for this range of parts and, more importantly, one that could be sold for half the price of the company’s Bystar 3015. Thus was born 50→80 ByVention, a unit that cuts 80 percent of today’s market volume at 50 percent the cost of today’s machines.

In the Update section of this issue you can find the technical highlights of ByVention. Here I want to address an even bigger breakthrough; what Töngi calls a new business model. ByVention is a high-technology cutting solution for companies that need automation in their cutting process but can’t afford the cost in equipment and floor space to make that 80 percent level. What Bystronic has done is not only to develop a machine that combines all the necessary hardware and software to produce quality cuts in 5 x 10 foot metal sheets, but also to do it on a machine that occupies the smallest amount of floor space (20x20 feet) and offer it at single worldwide selling prices, €265,000 ($318,000).

At that price, no discounts allowed, Bystronic will sell you a ByVention that is delivered to your shop floor anywhere in the world, and can be hooked to your utilities and be up and running in 2 ½ hours and be in full production in two days. The system is complete with laser, cutting motion system, load/unload features, controls, electrical cabinets, gas handling, dust and scrap collectors, and even two tanks of gas for the 2.2kW CO2 laser. Say again-that’s a complete unit ready to cut metal in two days, shipped from Niederönz and installed on your floor anywhere in the world for one sales price, no discounts, no options, no add-ons, a two-year warranty and preventative maintenance (consumables are extra), and with installation and training included. A third-year maintenance contract is mandatory. The only variable: customs duties and taxes.

As this unheard of offer is described I envision the company throwing down a gauntlet to the rest of the laser cutting system suppliers and to the turret punching industry. Their goal, yes, it’s to add another 200 units a year to their current annual output; but more to the point, it’s to expand the market for laser cutting and to do it with a simple, compact, clever, reassuring, and complete system, one they refer to as “plug and play.” I saw them drop Serial Number 18 on the floor at 10AM, had it hooked up and ready to test at 1:30PM, and after one hour of training had Mr. Töngi program and cut parts, all in the same day.

ILS is not a shill, nor are any of the other journalists at the preview. I know we all were more than impressed. Michael Zakrzewski, executive vice president and general manager of Bystronic Inc., said the goal of ByVention is to innovate not imitate. He was talking to customers but we jaded scribes read the underlying message as a challenge to the supplier industry. ILS thinks this is one of the most significant equipment introductions we have seen in our 21 years-significant enough for us to break tradition by putting a machine on the cover.

David A. Belforte

[email protected]