Multipass welding with laser and GMAW

Bremen, Germany—Joining thick steel plates using conventional gas metal arc welding (GMAW) processes, common in shipbuilding and pipe laying, requires a high number of different weld passes. Single pass GMAW is often not suitable for sheet thicknesses above 5mm, because the melt pool becomes large and difficult to control, coupled with a high heat input into the base material. Depending on material thickness, a different number of welding passes is required, performed one by one, sometimes at different working stations.

High-power laser systems can help to reduce the number of weld passes and improve the cost situation, with a welding speed increase and a decrease of heat input distortion and less rework for straightening. A promising approach that reduces the number of weld passes and welding time is hybrid welding, a combination of a laser with GMAW. This process also influences weld seam hardness and toughness by filler wire selection, as well as the chance to bridge gaps and correct for linear misalignment, which would not be possible using just the laser beam as an autogenous process. The small area heat input of the laser beam enables a deep penetration and high welding speed that in turn would not be feasible with a GMAW process.

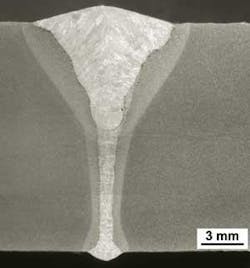

Reducing the number of weld passes and processing time were goals of the HyBright project funded by the BMBF (Federal Ministry of Education and Research). At BIAS (Bremen) an 8kW fiber laser with high beam quality was used to weld 16mm-thick steel plates with a hybrid process. Because 8kW of laser power is not enough to join thick plates in one pass, a joint preparation approach was chosen to weld them in two passes. A V-butt joint with a broad root face (Y-joint) was chosen as a seam preparation with root faces between 6 and 10mm and included angles of 45° and 60°. The root pass (see FIGURE 1) was welded with a hybrid process; the remaining groove was welded using a MAG (metal arc gas) process (see FIGURE 2).Using the hybrid process the root pass could be welded without problems, even with gap or linear misalignment. Gaps up to 1.2mm and linear misalignment up to 0.5mm can be bridged in the root pass. Depending on the root face welded, the welding speed was between 16m/min and 1.8m/min. For the filler pass welded with the MAG-process, the welding speed had to be decreased to 0.4m/min. With this welding procedure, a weld seam of high quality could be produced, free of internal defects such as cracks, pores, or lack of fusion. Compared to submerged arc welding, a high-performance welding process, the total time for welding could be reduced by 50%. A further reduction of welding time could be achieved by optimizing the welding of the filler passes increasing the profitability of the process.

Funding by BMBF for the project HyBright (FK 13N9278) is gratefully acknowledged.

Stefan Grünenwald ([email protected]) performed this work at BIAS (www.bias.de).