CO2 lasers find jobs in commercial woodworking

CO2 lasers are used in the sign making industry, for architectural modeling, the building products market, cabinetry, retail branding, and many other related businesses

Michael Rauch

Often, when people discuss lasers for use in industry, their focus is on processing metal components, plastic parts, and other manmade materials. There are also other viable commercial uses for lasers, mainly CO2, when processing wooden substrates. For example, these lasers are used in the sign-making industry, for architectural modeling, in the building products market, cabinetry, for retail branding, and other related businesses.

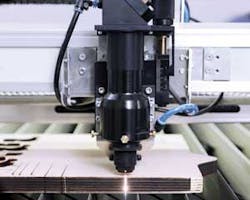

The terms laser cutting and laser engraving have unique definitions when processing wood. Engraving is the removal of material to create a texture, depth, or relief on the substrate (see FIGURE. 1). Laser cutting is fully sectioning or contour shaping the material for some end use (see FIGURE. 2).

For most wood processes, flatbed or XY plotter style machines have several advantages. The main benefits are a large engraving area and the introduction of the laser beam perpendicular to the target. The beam normal (90º) to the interaction with the wood surface allows for high-precision processing as well as eliminating the angled distortion associated with galvanometer based scanning systems. A drawback with flatbed XY systems is speed in processing individual parts where the galvo systems have an advantage. However, in most commercial applications wooden parts are not processed in high volumes so this is not a common detriment to choice of system.

Laser processing is especially attractive to the retail sector where branding is the key to the successful promotion of their products. Referring to Fig. 1, this winery ships their fine wines in a custom labeled box and desire a “wood burned” look to their packaging. For this application a Trotec SP500 (www.troteclaser.com) large-format laser was a perfect solution to their needs.

It is also possible to both engrave and cut material as a dual process. FIGURE 3 shows a custom produced sign that was used for decoration and promotion. This example shows the quality and precision that can be attained with a plotter type CO2 laser system. If this had been cut by hand and then engraved there would have been a higher possibility for human error and the total processing time to completion would have been excessive.

Another interesting application for a plotter type CO2 system is in custom cabinetry and inlay work. FIGURE 4 shows a piece of wood that was engraved to depth and then inlaid with a contrasting color wood veneer to create an eye-catching end result. In this application, the system’s precision motion allows this piece to be processed much faster than a manual operation, and with much less chance for mistakes.

The most common questions asked when considering a flatbed XY plotter type laser system to process wood are: what is the maximum thickness of wood that can be cut and is hardness of the wood a factor? Depending on the output power of the laser, the thickest wood that can be cut in one laser pass is typically about 0.5 in. However with multiple passes and vertical focusing increment changes it is possible to cut through wood 0.750 in. thick. Applications testing are usually required to determine the correct laser configuration.

Wood hardness is not as much of a consideration as is the wood type. Some woods have a homogeneous make up, with very little in the way of grain. These types of woods process extremely well in cutting and engraving applications. Wood with a highly defined grain or one that is knotty makes processing more difficult. The laser will react slightly differently to the grain and the final effect might not be what was expected. If cutting entirely through the material is the goal, then the flatness of the wood should be taken into consideration; the flatter the piece, the more consistent the cut.

All wood, when heated during processing, will get slightly tacky as a result of resin in the wood bubbling to the surface from the heat generated by the process. In most cases the sticky residue can be removed by a quick sanding pass or a wipe with mineral spirits, typically tasks already common in most woodworking environments.

The other thing to consider is the fact that wood is flammable, therefore it is imperative that two elements be introduced to the process to all but eliminate any chance of an unexpected flame-up. The first one is a compressed air source. The Trotec SP500, like most lasers in its class, has a directional compressed air nozzle that delivers air coaxial with the lasing beam that controls possible ignition of the wood by cooling the surrounding area while it blows out the charred material caused by the lasing process. All wood will char at the cut location to some extent. This is caused by the heat of the laser interacting with the resin in the material and also with oxygen and water retained in the wood itself. In most cases this is very minimal, but if required a quick pass with a sander will remove this discolored area.

Charring can be controlled on many wood types; if required in an engraving application where the beam does not penetrate through the wood or if material is processed at the right speed with low power or multiple high-speed passes. Some people prefer the artistic shading of the char so the wood-burned effect is desirable. If not, and the settings are adjusted correctly, an almost perfect engraved look is possible with just the slightest discoloration, which might not be construed as charring.

The second critical element is proper smoke evacuation. Laser systems should have an exhaust hose attached adjacent to the lasing area that travels with the plotter head. This allows the smoke to be easily removed helping to keep the laser processed part and the laser optics as clean as possible. The hose can vent to a filtered exhaust system, or can be expelled outside the facility, depending on the local environmental laws and the proximity to other facilities.

Summary

CO2 laser processing can be a major benefit to companies where there is a required need for cutting, product identification, branding, or decoration. Wooden substrates are the focus of this article, but the fact is CO2 lasers can also cut, engrave, or mark most plastics, ceramics, coated metals, and even some bare metals makes, which makes them a versatile and productive tool for almost every industry.

Michael Rauch ([email protected]) was formerly with Trotec Laser Inc. Ypsilanti, MI. Trotec is based in Wels, Austria (www.troteclaser.com).