Products

Compiled by Laureen J. Belleville, [email protected]

Linear motor Cartesian gantries

AGS15000 series Cartesian gantries from Aerotech Inc. (Pittsburgh, PA; www.aerotech.com) are designed for ultra-precision, high-dynamic contouring. The planar design minimizes dynamic pitch errors at the work point. According to the company, these gantry systems provide outstanding performance and versatility in a wide range of automation platforms, including precision micromachining, stencil cutting, fuel cell manufacturing, printed electronics, flat sheet processing, high-speed pick-and-place, automated assembly, vision inspection, dispensing stations, and high-accuracy inspection. The company’s BLM and BLMH series brushless linear servomotors drive the AGS15000 to speeds of 3 m/s and accelerations of 5 g. Dual linear motors and encoders are included on the lower axis for performance and precision. The rugged noncontact optical linear encoders offer resolutions to one nanometer when coupled with Aerotech’s encoder multiplier. Optimized to account for thermal expansion, this gantry design ensures high accuracy under varying operating conditions.

Next-generation 4 kW diode laser

Laserline (Muelheim-Kaerlich, Germany, and Santa Clara, CA; www.laserline.com) announces its next generation of high-power diode laser systems for industrial applications. Diode lasers now reach 4000 W with a beam quality equivalent to that of lamp-pumped Nd:YAG systems. Fiber delivered, the beam can be focused down to 0.6 mm with a 200 mm focusing length. Designed with the application in mind, welding processes in steel and aluminum as well as fine cladding are well within the abilities of this new generation of diode lasers. Very high beam quality lasers such as fiber or disk lasers are not necessary, and may even be detrimental when it comes to the ability to bridge gaps or reach a minimum weld width. According to the company, the next generation diode laser’s beam parameters are tailored towards welding processes, and offer the most economical solution. A small footprint, low maintenance, and an efficiency of up to 45% directly translate into real life cost savings, up to 10 times lower than that of a lamp-pumped YAG laser.

Variable focus industrial laser module

Photonic Products (Hatfield Broad Oak, UK; www.photonic-products.com) announces a new range of variable focus industrial laser diode modules constructed to withstand harsh conditions. These products offer the high performance and the high boresight accuracy of <0.25 degrees of the existing range of standard industrial laser modules with the added bonus of user-adjustable focus for greater flexibility and fine tuning. The range is designed to be a complete OEM laser solution for processes such as micromachining, marking, cutting, drilling, welding, forming, soldering, and many other industrial laser uses where superior quality, durability, and robust performance are critical. To this end, the industrial modules are encapsulated in a hard-coat anodized case with a scratch-resistant sapphire window to protect the lens.

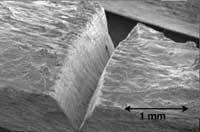

Better gas flow with laser cutting

Precitec (Gaggenau, Germany; www.precitec.de) has significantly increased the flow rate through the cutting nozzle while keeping the cutting gas pressure constant. The new KT B CON ceramic part and the nozzles now have no “hard edges” and have a conical geometry. Thus the cutting gas pressure can be significantly reduced while giving the same cutting edge quality, and the input pressure directly on the processing head can be reduced. Field tests with the new, considerably cheaper design have also shown an increased working range for the focal position. Dirt on the focusing lens and the associated focus shift can be detected with the larger process window and increase the operating life of the optics. With CO2 cutting heads without a protective window in particular, this leads to considerable cost advantages.

Compact laser power monitor up to 20 kW

Laser power is the central figure characterizing the laser beam and directly controls the performance of materials processing. However, the power indicated at the laser does not always reach the workpiece. Absorption within the beam path at defective components or changes within the calibration of the laser internal power meter may occur. Differences can be presented and documented easily with the CompactPowerMonitor (CPM) from Primes (Pfungstadt, Germany; www.primes.de). Primes calibration service ensures long term accuracy of the CPM. The product group with plane absorber consists of: CPM-F-1 up to 1.4 kW, the CPM-F-10 up to 10 kW, and the CPM-F-20 up to 20 kW. Optional adapters for many standard fiber couplers are available ready to measure the output direct from the fiber output.

Air-cooled picosecond laser

The APL-500-1064 (5 ps, 25 µJ @ 10 kHz, M2 <1.2) is a fiber based diode-pumped solid-state laser that can be pulsed on demand from 0 to 500kHz. These ultrafast lasers combine the advantages of robust fiber laser technology with the high energies of solid-state diode-pumped free space amplifiers. Designed by Attodyne (RPMC, O’Fallon, MO; www.rpmclasers.com) the APL incorporates a non-traditional laser cavity that is not susceptible to misalignment or in need of frequent maintenance. The modular design of the Attodyne laser allows it to be customized to meet various application needs for power, pulse energy, rep rate, and wavelength. High energy near-IR units are available with energy levels of ~50mJ at low rep rates.

Scan system

LIMO’s (Dortmund, Germany; www.limo.de) g2T scan system combines two different optical concepts—the transformation of Gaussian beams into homogeneous top hat profiles with a scan-method involving galvo mirrors and a specially designed f-theta objective lens. This system is constructed for laser direct materials structuring with conventional single-mode lasers specifically at 532 nm, in particular for solar cell manufacturing. Standard spot sizes of 50 x 50 µm2 are able to structure high-precision grooves with smooth edges in contrast to the typical sawtooth patterns caused by Gaussian beams. Moreover, the process window is enhanced and thermal damages are reduced by the homogeneous profile.

400W fiber laser

The JK400FL from GSI Group (www.gsiglasers.com) has all the advantages already demonstrated by the other units in the range, but with increased power and performance. Capable of faster processing speeds and the capacity to cut and weld thicker materials, these improvements make for a highly efficient machine that is both time saving and cost effective. According to the company, applications laboratory analysis shows superior performance over traditional laser processing with increased cut quality and speed, lower dross levels, and smooth spatter- free welds. The stable single resonator and in-built pulse shaping capability are other features that make this laser stand out from the crowd. Despite the increased power GSI has kept the JK400FL compact and simple. The absence of free space optics means there is a little or no maintenance required.

Air-cooled nanosecond fiber lasers

The JenLas fiber ns 10-30 Watt from Jenoptik (Jena, Germany; www.jenoptik.com) are air-cooled fiber lasers with an adjustable pulse length of 9 to 200 ns. Besides marking and labeling, they are well suited to perform a variety of cutting, drilling, and structuring jobs. Depending on the product model, peak pulse power of up to 15 kW can be achieved. The JenLas fiber ns 10-30 Watt are available in basic versions and advanced versions, each version representing a particular performance class. The basic systems with 10 or 20 watt power provide a modulation range from 1 to 100 kHz and fixed pulse lengths. The basic systems are hardware controlled. The advanced systems with 12, 20, and 30 watt power offer extended control capabilities and an enhanced range of performance. In addition, they facilitate CW operation and pulse repetition rates of up to 500 kHz with flexible pulse lengths adjustment.

Laser welding system

The new LQ-Vario from LPKF (Erlangen, Germany; www.laserquipment.com) is a flexible and compact laser welding system specially equipped for the economical processing of small and medium sized production volumes. Further applications are prototyping and process development. In addition, LPKF supports component suppliers with comprehensive expertise on materials, clamping, processing, and in-line technology.