Industrial laser shipments down 15 percent last year

At $422.8 million, 2002 shipments of industrial laser equipment and systems for North America and U.S. exports were down 15 percent from year earlier levels, according to the Laser Systems Product Group (LSPG) of AMT—The Association For Manufacturing Technology. Industrial laser equipment and systems shipments within North America by the 43 companies reporting to the 2002 LSPG statistical program totaled $311.2 million, while exports amounted to $111.5 million.

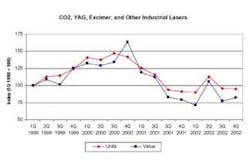

The report from the LSPG shows that shipments of CO2 laser systems remained level and Nd:YAG lasers were down 30 percent. The report also shows cutting applications as the largest source of industrial laser activity in 2002, accounting for more than half of all shipments. In addition, nearly 60 percent of all industrial lasers shipped for the year were of the CO2 variety and more than 80 percent of total shipments were configured as a laser system (laser source + workstation). According to the LSPG report, shipments of industrial lasers in units ended fourth quarter 2002 with a near return to first quarter 1999 levels after peaking in third quarter 2000 (see figure).

Full year 2002 dollar figures are based on data supplied by contributors to the LSPG statistical survey. The year-on-year decrease of 15 percent and the percent change in CO2 and Nd:YAG lasers reflect the contributions of only those companies that participated in the statistical program in both full year 2001 and full year 2002. The report does not include increased shipments reflecting the addition of new program participants in 2002.

The Laser Systems Product Group comprises AMT member companies that produce laser systems and industrial laser sources. The LSPG operates as a forum for the industrial laser systems supplier community, acting cooperatively to increase the rate of growth of industrial laser products and systems in North America. While LSPG members must be members of AMT, any North American company building or supplying industrial laser equipment may participate in the LSPG statistical program.

Confidentiality in the LSPG statistical program is guaranteed. In more than 100 years of managing market data reports, AMT has never had a breach of confidentiality. Data collection forms are coded and company data is used only in summary statistical tabulations. The LSPG statistical program covers an estimated 80 percent of the North American market for lasers used in materials processing on the factory floor and about 65 percent of the U.S. export market. The report includes industrial laser materials processing such as cutting, welding, drilling, marking and other applications, however it currently does not include lithography, inspection, control or measurement.

Companies that meet the eligibility requirements and would like to participate in the LSPG statistical program should contact Diyana Hrzic, Industry Economist, at (703) 827-5289 or [email protected]. ˆFor more information about the LSPG and its efforts to promote the industrial laser industry in North America, please call John Effmann, vice president—marketing and public relations, at (703) 827-5290 or jeffmann@ AMT.online.org.

LSPG, 7901 Westpark Drive, McLean, Virginia 22102