From welding to polishing

Laser welding and laser polishing are thermal procedures for remelting predominantly metallic materials supported by supplying a shield gas. These automated technologies substitute for manual activities and increase the quality of the weld joint and the surface. While CO2 and Nd:YAG lasers in the power range up to a few kilowatts do laser welding predominantly, for laser polishing a diode-pumped 100W Nd:YAG laser has been successfully employed.

This 100W Q-switched laser, DiNY Plus from IB Laser (Orlando, FL, and Berlin, Germany), contains a double cavity resonator design, which incorporates a symmetrical resonator with power reserve to 150 W and a beam parameter product M2 of 15. For the polishing application in the power range of from 70 to 100 W, thermal lensing is minimized to reach a multimode beam parameter product M2 between 7 and 9. Thus the beam can be coupled to a 200-µm fiber. Under normal focusing conditions and working distance, the average power density is 10 kW/cm2 with >1 MW/cm2 in the application spot. The peak power refers to a minimum pulsewidth of 40 ns. This is pertinent to many different applications, including laser polishing, which require high power density and average power.

null

In practice, the laser beam melts and remelts material over a large surface area and vaporizes microscopic points and ridges. This restructures the surface to a depth of about 50-µm and smooths residual mechanical or erosive production material without causing any deformation or surface cracks. Then surface microstructures that led to diffuse reflection of light are removed, with a resulting shiny surface (see Figures 1, 2 and 3). Patented by LFC AG (Laser Finishing Center—Herzogenaurach, Germany), these processing steps were developed in cooperation with the Fraunhofer Institute for Laser Technology (ILT—Aachen, Germany) in a research project lasting several years.

It is important that the specified dimensions and edge radii are achieved. At present a combination of pulsed and continuous laser radiation is used to smooth the surface of milled and eroded tool steels. Polishing of other metals and non-metals is currently being researched at LFC AG.

Conventional mechanical polishing techniques use different grades of polish applied in successive steps, with thorough intermediate cleansing. A conventional normal polishing rate of 30 min/cm2 is unacceptably long. Automation in this process is virtually absent, so highly skilled workers are required as well. Currently, polishing job shops perform this task for larger manufacturers. Safeguarding against accidental damage, if .small contours are present on the workpiece, also increases the polishing time. The laser polishing process achieves a manufacturing speed between 2.5 min/cm2 and 4 min/cm2 with a current surface roughness of Ra ~ 0.25 µm. The best results, on selected steel, achieved a Ra of 0.05 µm. If optical quality is required, mechanical processes are still superior; achieving surface roughness down to 0.01 µm on a longer time scale, but an estimated 80 percent of industrial applications settle for a surface quality of about 0.15 µm.

In order to have exact control of the energy penetration, the dynamic of the laser has to meet high requirements in axial speed, acceleration and pointing accuracy, making beam delivery with an optical fiber mandatory. This requires a different layout of the machine hardware.

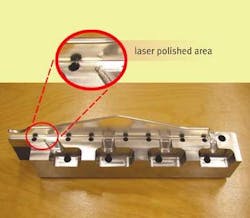

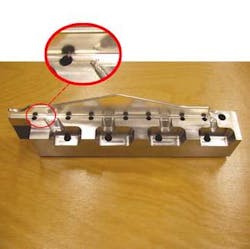

LFC AG now operates three unique models of laser polishing machines for serial production and also offers laser-polishing services. For polishing large workpieces, a machine with a 5-axis gantry system was developed. The base, a stone portal with traveling linear axes, is integrated with a laser unit and a Siemens Sinumerik 840D CNC. The laser light is supplied via an optical fiber (described above) to the processing optics. The gantry system is also equipped with two rotational axes for positioning the processing head to ensure that the laser beam impinges on the surface of the workpiece at the right angle, thus achieving 3D control. An example of a two-foot workpiece, an auxiliary molding tool used in the automobile industry, is shown in Figure 2.

null

The selection of workpiece segments to be polished and the programming are based on a standard CAD/CAM solution and supplemented by a postprocessor developed by LFC AG. This software solution enables the polishing of three-dimensional segments of the surface of the workpiece. Special treatment of edges is currently under test.

For small workpieces, mostly in large quantities, a higher dynamic of the axes is necessary to speed up the process. A study showing the ability to polish vertical and horizontal planes in one processing step is shown in Figure 3. A combination of a galvo scanning head and a three-axes handling system is deployed. This is in contrast to the five-axis gantry system, where the workpiece is moved on a carriage. Here the laser beam is delivered directly to the scanning head. In its latest stage, a special scanner is applied, which allows almost complete one-sided 3D processing without moving the workpiece. This scanning head, nicknamed "Elephant," was developed by the Arges company (Nabburg, Germany). It possesses a third optical axis, which allows moving the laser beam in z-direction with high speed also.

null

With laser welding as an established contactless and substance-free remelting technique, this novel material processing method is finding applications in molding, tool making, medical technology and motor components and enables the handling of a wide range of workpiece sizes. Recent examples include watches for a large Swiss company, artificial heart valves and small-scale valves for bio-chemical process control.

With the aid of the field-proven, short-pulse 100W special mode profile laser, the vision is to complete the development by extending it to surface structuring, edge hardening and die spotting application joints. This surface remelting process may also serve to smooth out the elevated structures created by traditional laser welding.

U.K. Jarosch, F. Massmann and B.Smandek are with IB Laser, Orlando, FL, and Berlin. J. Schmidt is with LFC, Herzogenaurach, Germany. Contact IB Laser at Tel. (407) 438-7600 or visit www.ib-laser.com.