Laser spike-welding

Philips CFT, Centre for Industrial Technology, creates value in innovation and industrialization for Philips and selected external companies. Focus areas are innovation and industrial consulting, mechatronics and equipment technology, precision product and process technology, material and contamination analysis, and new product introduction services. Support ranges from product development to process, equipment and industrial development, and initial supply.

For more than 25 years Philips has applied laser welding in mass production. Product examples are the electron gun for CRT displays, wires and electrodes for lamps, and razor knives in electrical shavers. A recently developed novel spot weld process is "laser spike-welding." This technique was investigated for an overlap penetration geometry (two sheet metal plates on top of each other) using 0.2–0.6mm thick metal sheets. It was found that extremely large gaps of 100 percent of the top layer thickness and more can be bridged in overlap penetration geometry. This is a real breakthrough, because with conventional (keyhole) penetration welding the acceptable gap size is only 20–40 percent at most. With the novel laser spike-welding technique we can weld parts with much larger dimensional tolerances in production. In addition it gives new possibilities for mechanical engineers to create alternative product designs in which large gap constructions are chosen for functionality reasons.

Special pulse shaping does the trick

For the experiments we used a pulsed solid-state welding laser with pulse-shaping capability, such as TRUMPF's HL204p. This laser can provide 8 kW peak power and 20 ms maximum pulse time with a wavelength of 1064 nm. The pulse shapes (power as a function of time) can be programmed with a PC. The shortest sector time is 0.1 ms. The experiments that are described next have been done with a laser spot diameter of 600 µm and common sheet metal of 250µm thick stainless steel, X8CrNi1812.

With the laser pulse a quiet local melt is created in the top plate at a power level of 325W using simple heat conduction. Then after 15 ms, this molten volume is pushed towards the opposing plate by applying a sudden spike (power level 1650 W, duration 0.3 ms) on the incident laser power. During this spike, a vapor plume creates a constant recoil pressure of typically 0.25bar on the melt, which is pushed towards the opposing plate. After wetting and solidification the weld is finished (see Figure1).

Extreme gap bridging

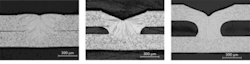

With spike-welding, large gaps can be bridged in production. Variable gaps are the result of dimensional tolerances of parts and positioning equipment. Figure 2 shows experimental results with 0-, 50-, and 100-percent gaps, respectively. All welds have been made with the same parameter settings.

It was found that the spike weld process is very robust. The observation is that once the melt touches the bottom plate, it will always wet the bottom plate and a repeatable weld strength is obtained, depending only on the gap size. Figure 3 shows laser spike-welding of an axis in a wide tube. The axis can be aligned prior to welding and has much play. The actual gap spacings at the spot-welding positions are not well defined. However, with a single laser parameter setting and three simultaneous welds we fix the axis in the tube at any position.

Following are examples of spike welding for special product designs. Example 1 is a simple metal multi-layer stack (see Figure 4). Metal sheets are welded on top of each other, one after the other. The gap width is set prior to welding with a temporary sheet spacer. Application possibilities are manifold, such as ridged and lightweight constructions, where the multi-layer can afterwards be filled with epoxy. The multi-layer stack could also serve as a passive heat shielding construction in turbines or car engines, or it could be used for quick cooling of liquids in the food process industry. Finally the multi-layer could be applied in VIP (Vacuum Insulated Panel) type of constructions, or as mechanical impact absorbers.

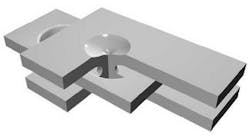

Example 2 is laser riveting to reduce fabrication costs. An intriguing example is shown in Figure 5. Here the spike-weld serves as an axle in a hinge or sliding-plate construction. The construction is inexpensive because no additional screws or spacers are required.

Figure 6 shows a different laser riveting application. One or more disc-shaped 'laser rivets' can be applied to clamp sheets of plastic or ceramic to a metal base.

New applications

With laser spike-welding a novel laser penetration weld tool is obtained. Good welds can be made, even if the gap between the metal plates is up to 100 percent of the top plate thickness. This is a factor 2.5 to 5 larger compared to conventional keyhole laser penetration welding.

Laser spike-weld technology offers new and inexpensive construction opportunities. Meanwhile at Philips, laser spike-welding is applied in mass production.

Some application areas are: designing of product parts and processes with larger dimensional tolerances (more robust weld processes and process cost reduction); and possibilities to create novel constructions in which large gaps are chosen to obtain specific functional properties.

Willem Hoving is with Philips CFT, Centre for Industrial Technology, Eindhoven, The Netherlands, and Durandus Dijken is with Philips Lighting, Eindhoven, The Netherlands. Contact Hoving via e-mail at [email protected]. See also www.cft.philips.com.