Time for a turnaround

On November 16 the doors to Chicago's McCormick Place will open to once again host Fabtech International, North America's largest annual metal forming and fabricating exposition and conference. More than 40 laser, system, and component manufacturers will be on hand, with a cautious optimism, to display their latest products and technology.

By the end of 2003 more than 37,000 laser sheet metal cutting systems will have been installed worldwide. Not bad for a technology that only began to take off in the late 1980s thanks to customer demand from job shops in Germany and Japan. With the addition of a substantial North American market in the mid-1990s the sales of laser sheet metal cutting equipment became a billion-dollar business, about one-third of the total annual industrial laser system revenues.

The zenith, in terms of units sold, was reached in 2000 when more than 3000 units were installed in the world's industrialized nations, including the beginnings of a now vibrant market in China. The past three years have not been as vibrant, as global recession in one nation after another severely impacted annual sales.

The job shop market, that sector that uses laser metal cutting as either a main source of revenue or an adjunct to other fabricating services, remains the key to laser cutter sales. In North America this sector accounts for about 80 percent of systems sold annually. This market sector has been in the throes of change. Diversified shops, those offering more than just laser cutting, have managed the recession better than most, many even adding automated equipment. Marginal, cutting only, shops have left the market, with their laser cutters clogging the used machinery market.

Some industry observers have questioned whether the laser metal cutting equipment business can recover to pre-recessionary levels. ILS has considered this issue and, based on interviews with industry suppliers and leading users, we believe that the global market will, over the next few years, gradually climb back to profitable, modest growth levels. Our current thinking is that an annual growth rate of 7–9 percent is doable. This is about half the year 2000 rate, but that was an extraordinary year even in good times.

We looked at the market from 1995 to 2002, a period we consider as the golden years for the industrial laser business, and found that annual sales averaged 2200 units. If you take out the banner year 2000, it's a bit over 2000 units. This year the industry is on track to come close to this average. And a modest 5–6 percent growth rate in the next two years would have sales back on the ten-year average level.

We have heard and read many arguments that the glory days of laser cutter sales may be behind us. Much of this stems from people who enjoyed the 1997–2000 boom years where sales averaged about 2700 units/year.

There are many reasons why the laser metal cutting market has plenty of life left in it. New technology in laser power, system automation, software, and maintenance procedures make the current crop of laser cutters more flexible and productive. We continue to meet shop owners who have invested in this new technology even in a down job shop market. Now that the bulge of used systems has been reduced, the market for new equipment has perked up. For this year we anticipate a 3–4 percent growth over 2002 sales.

In assessing the impact of the recession on job shops we have noted one important factor, shops that serve a diversified customer base with flexible, high-productivity equipment came through the downturn without too many battle scars. Those shops that focused on niche markets, served by less-productive laser cutters did not, on the whole.

Our conclusion is that, to compete in today's market for laser cutting services you will need modern equipment. Of all the laser cutters ever built, about 85 percent are still in operation somewhere in the world. That means there is a lot of "old" equipment still active. Many of the "inactive" systems are those that were built and installed prior to 1990. Dating the installed base back to 1995, when 1500 watts was the standard laser power, we find about 22,000 units are active and about 20 percent of these systems are candidates for replacement with higher power, more automated systems. So the replacement market alone could be a driving force for recovery back to improved annual sales.

If you would like to share your views of the current job shop market stop by the Industrial Laser Solutions booth, 17154, and visit with us at Fabtech. Also be sure to visit with the following companies and check out the products we have detailed below.

Fabtech exhibitors

Amada (Buena Park, CA) features the Gemini FO-3015 laser and the new expandable multi-tower laser automation system. Amada Intelligent Manufacturing Software interfaces directly to an MRP system or simple database. The compact, entry-level Quattro laser is also on display.

The Adige LT803D, from BLM Group USA (Wixom, MI), multi-axis laser tube cutting system can produce both normal and bevel cuts. for round, square, rectangular, flat oval, and other tubular shapes.

Mazak's (Schaumburg, IL) lasers perform ultrafast cutting of sheet metal while maintaining tight dimensional accuracy and consistent cut quality. The FG-150 is demonstrating its ability to automatically load, feed, 3D laser cut, and unload mill-length materials with a 5.9-inch diameter.

Ultimate Automation by Mitsubishi Laser (Wood Dale, IL)—high-productivity software developed by Ncell Systems—powers the LVP 3015 with the 40CFX cross-flow resonator and MSC III material handling system.

Prima Laser Tools' (Chicopee, MA) Domino multi-axis laser system combines 2-D and 3-D cutting capabilities in a single, cost-effective machine. The system is available with a 2500W, 3000W, or 4000W CO2 laser resonator.

TRUMPF Inc. (Plymouth Township, MI) introduces its TC L 2510 LX FMC, which combines a load and unload device with high-speed laser cutting. Also debuting is a compact five-axis laser machine, the TLC CUT 5, which was designed for laser cutting of formed and other 3-D parts.

Bystronic (Hauppauge, NY) will be displaying its newest resonator technology and an updated Byspeed with enhancements that make it capable of cutting more than 600 round holes per minute and square holes even faster .

Optimized for laser cutting, SigmaNest from SigmaNest (Cincinnati, OH) features feed-rate ramping on corners, vaporizing, pre-piercing, and first inspection part.

Telesis (Circleville, OH) presents its Zenith 10F fiber-to-fiber laser marking system featuring a lightweight platform, easy integration, and up to 30,000 hours of 24/7 operation.

LaserMate, from Windsor Laser Cutting Inc. (Windsor, Ontario, Canada), is a semi-automatic sheet and plate loader for lasers or plasmas.

Precitec Inc. (New Hudson, MI) features the new generation Lasermatic and Lasermatic Z HP 1.5"M and HP 1.5 MZ cutting heads. The company has converted the YW50 welding head to a YC50 cladding head. It is also introducing a Scraper Sensor System for the Laser Weld Monitor, a real-time laser welding monitoring system .

American Laser Enterprises Inc. (Northville, MI) introduces two industrial CO2 laser cutting heads to retrofit or upgrade flatbed sheet cutters. The 020016 modular cutting head features a cartridge-style lens holder and is available in 5.0-in, 7.5-in, or combined 5.0–7.5-inch focal length set up. The 020014 Mazak Retrofit cutting head contains the same features as the modular cutting head but is specifically designed as a plug-and-play replacement for the Mazak tactile cutting head. American Laser Spares LLC (Novi, MI) features the retrofit products manufactured by Precitec Inc. and American Laser Enterprises Inc.

Laser Mechanisms (Farmington Hills, MI) will show its line of laser beam delivery components and articulated arm systems, including the Mazak cutting head upgrades.

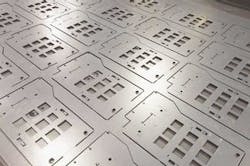

Fraser Precision Tubular Parts (Albertville, MN) has an Engineered Solutions Group that helps customers eliminate unnecessary manufacturing processes and delivers their completed components faster. The company's new laser technology and manufacturing processes offer closer tolerances, minimal heat affected zones, and burr-free parts with an enhanced degree of accuracy and repeatability.

Concoa (Virginia Beach, VA) will display gas-blending systems featuring a new CO2 analyzer and an alarm with a unique software package. Also, a new fully automatic laser assist gas switchover is microprocessor controlled and minimizes residual gas loss.

Riedel USA Inc. (Plymouth Township, MI) offers an insertion cooling module with a cooling capacity of >1 kW. The company also offers a portable process chiller with a cooling capacity between 1 and 8 kW.

Lens Savers from International Crystal Laboratories (Garfield, NJ) are crystal optics that shield focusing lenses and other optical components of a laser from damage arising from the spatter discharged during laser welding or cutting.

In addition to its AR-coated CO2 focusing lenses Ophir Optronics (Wilmington, MA) manufactures the Black Magic Duralens line of low-absorption optics.

II-VI Inc. (Saxonburg, PA) will display the MP-5 high-power focusing lens, a selection of CO2 replacement optics, and a new line of.CO2 replacement nozzles and accessories.