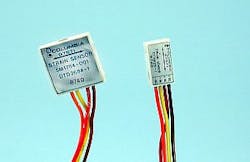

Strain sensors from Columbia Research Associates monitor fatigue loading

The DT series of strain sensors allow undercarriage structures and surfaces to be more accurately monitored compared to counting accelerometer methods. These rugged sensors incorporate the technology of the flight-qualified DTD2684. Series DT3625 Sensors offer a package of 0.45 × 0.25 × 0.14 in. thick and weigh only 13 grams. They are designed to monitor the fatigue loading experienced by aircraft under various conditions of flight speed, weight, and mission configuration.

Columbia Research Laboratories

Woodlyn, PA

[email protected]

-----

PRESS RELEASE

HIGHLY ACCURATE STRAIN SENSORS MONITOR FATIGUE IN AIRCRAFT

Columbia Research Laboratories, Inc. offers a family of strain sensors that allow critical undercarriage structures and surfaces to be more accurately monitored than by using less accurate counting accelerometer methods. All of the sensors in the DT Series incorporate the proven technology of the flight-qualified DTD2684. Designed to monitor the fatigue loading experienced by aircraft under various conditions of flight speed, weight and mission configuration more accurately than older technologies. All of the sensors in the DT Series are easy to install and feature rugged construction. Basic technology, including self temperature compensating and high output has been enhanced in some models to meet specific application needs.

Series DT3625 Sensors, developed to measure fatigue in tight spaces, offer a package of 0.45” x 0.25” x 0.14” thick and weigh only 13 grams. DT3617 Foil Strain Sensors are designed to measure planer shear strain forces when the axes of principal strain is identified. Each sensor is a complete, compact, easily installed device. DT3715 sensors accurately measure both strain and temperature on curved mounting surfaces. DT3716 sensors measure both strain and temperature on straight mounting surfaces. Both series offer all the accuracy, ruggedness and ease of installation of the flight-qualified Series DTD2684.

Columbia Research Laboratories, Inc. is ISO9001:2000 with Design & AS9100 Revision B certified.

For more information call 1-800-813-8471; Fax: 610-872-3882; e-mail: [email protected]; or visit www.columbiaresearchlab.com.