Ditzingen, Germany--A team from Coherent GmbH (Göttingen, Germany) and Bruker HTS GmbH (Alzenau, Germany) has been recognized by the Berthold Leibinger Foundation for its pioneering work in the mass production of high-temperature superconducting (HTS) tape. Team members Dr. Ralph Delmdahl, Rainer Pätzel, and Dr. Kai Schmidt (all of Coherent) and Dr. Alexander Usoskin (of Bruker HTS) received the Berthold Leibinger Innovationspreis 2010 (second place) at a ceremony July 9 at Trumpf headquarters.

The excimer-laser-based mass-production process for ceramic HTS tapes uses pulsed laser deposition (PLD) to produce the tapes at higher throughput rates than has previously been possible.

Since their discovery in 1987, high-temperature superconductors have offered tremendous promise to displace low-temperature superconductors (LTS) in applications like magnetic resonance imaging (MRI), and to enable new applications such as so-called “smart” power grids.

The advantage of HTS materials is that they can operate at liquid nitrogen temperatures (-196°C), whereas traditional LTS materials require cooling with liquid helium. The latter is expensive to implement due to the high cost of liquid helium and the extreme thermal insulation required.

However, HTS materials are brittle, so production of a flexible, wire-like product is challenging. Typically, a layer of HTS is deposited on a thin metal support tape using a technique such as pulsed laser deposition. Here, a pulsed laser ablates a target and the vaporized plume of material recondenses on the nearby substrate. The entire process is carried out under vacuum. Both 248-nm and 308-nm excimer lasers have been used successfully for PLD, but the process has been limited to wafers (up to 8 in./200mm) and lengths of tape up to 100 meters. But there is huge existing and future market potential if HTS tape can be mass produced in longer lengths. A single MRI machine, for instance, uses 200 km of superconducting wire and more than 3000 of these machines are shipped each year.

Increased production rates of the HTS tape cannot be achieved by simply directing more laser power at the HTS pellet because there is an optimum laser fluence required to vaporize the HTS and maintain its stoichiometry.

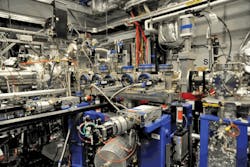

In response, Bruker has pioneered a “multiple plume” method using novel geometries and substrate handling techniques to perform parallel processing. Here the output of a high-power excimer laser is split into multiple beams, each focused on to a different site, simultaneously depositing material along an extended area of tape. Mass production needs sufficient pulse energy to drive multiple plumes above their threshold energy, plus a high pulse repetition rate.

The Bruker effort has been closely supported by the team from Coherent’s Göttingen-based excimer group which has developed a high power version of its Lambda SX series of lasers. The Lambda SX 540 C model provides stabilized energy operation at up to 900 mJ and repetition rates as high as 600 Hz at a wavelength of 308 nm. Moreover, this laser offers both the gas lifetime (over 750 million pulses between gas fills) and pulse to pulse (<1%) energy stability that are prerequisites for this HTS application.

The Berthold Leibinger Innovationspreis is awarded biennially to individuals and groups that “have completed publicly accessible, excellent, scientific work or produced an innovative technical development in the field of applied laser technology.” It is one of the highest remunerated international innovation prizes for laser technology. Three prizes are handed out with a total of 60,000 Euro (~$78,000), none of it earmarked for a specific purpose.

For more information visit the Leibinger Foundation WebsiteAbout the Author

Stephen G. Anderson

Director, Industry Development - SPIE

Stephen Anderson is a photonics industry expert with an international background and has been actively involved with lasers and photonics for more than 30 years. As Director, Industry Development at SPIE – The international society for optics and photonics – he is responsible for tracking the photonics industry markets and technology to help define long-term strategy, while also facilitating development of SPIE’s industry activities. Before joining SPIE, Anderson was Associate Publisher and Editor in Chief of Laser Focus World and chaired the Lasers & Photonics Marketplace Seminar. Anderson also co-founded the BioOptics World brand. Anderson holds a chemistry degree from the University of York and an Executive MBA from Golden Gate University.