Intertronics silicone potting and sealing material withstands UV-visible light exposure

Dymax Cure-Point 9440-A/B silicone potting and sealing material cures to depth in seconds upon exposure to UV-visible light to provide protection to electronic components and circuitry. Room temperature mix life is >90 days, and operating temperature range is -40° to 200°C.

Intertronics

Oxfordshire, England

www.intertronics.co.uk

-----

PRESS RELEASE

CURE-POINT™ 9440-A/B UV SILICONE FROM INTERTRONICS

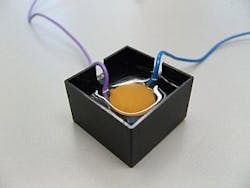

OFFERS SUPERIOR PROCESSING OVER RTV AND HEAT-CURE SILICONES

Intertronics are pleased to announce Dymax Cure-Point™ 9440-A/B silicone, which cures to depth in seconds upon exposure to UV/visible light to provide protection to electronic components and circuitry. It is a UV/visible light-curable silicone potting and sealing material designed for applications where fast cure, enhanced thermal performance and room-temperature shadowed-area cure are required. Cure-Point 9440-A/B has a ›90 day room temperature mix life.

This product is designed to withstand long exposure to temperatures ranging from below -40°C to above 200°C while retaining fast-cure processing benefits associated with UV-curable materials. This makes it superior to RTV silicones and heat-cure silicones which require longer cure times or elevated temperatures to cure. Cure-Point 9440-A/B excels in applications where oil or chemical exposure are present. It also features a fast, tack-free cure with negligible shrinkage.

Dymax UV/visible light-curable materials are solvent free and their ability to cure in seconds results in lower processing costs. Intertronics also offer light-curing spot lamps, focused beam lamps, or flood lamps, matched to deliver optimum speed and performance for maximum efficiency, as well as lamps offering the optimum balance of UV and visible light for the fastest, deepest cures. This product is in full compliance with the RoHS Directives 2002/95/EC and 2003/11/EC. Further information regarding Intertronics’ products can be found at www.intertronics.co.uk.

Subscribe now to Laser Focus World magazine; it's free!