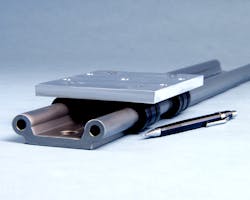

Linear slide from LM76 for noncontaminating linear motion applications

The Whispah linear slide is designed for noncontaminating linear motion applications such as medical, pharmaceutical, and food processing equipment. The WSP 1 Twin Rail System features a 4 × 5.5 in. table with a bearing measurement of 2.125 in. The WSP 2 measures 6 × 7 in. with a bearing centerline to centerline of 2.906 in.

LM76

East Longmeadow, MA

www.lm76.com

-----

PRESS RELEASE

Low Cost, Extremely Quite WhispahTM Linear Slide Is For Any Environment!

E. Longmeadow, MA – The new WhispahTM Linear Slide is low cost, has very smooth motion, and is exceptionally quiet. Designed to fully utilize the outstanding properties of LM76's Minute Man Linear Bearings series such as: Low friction, high load capacity, high speed (400 SFM), shock absorption, self lubrication, zero absorption, very low friction (0.09 to 0.12 C of F), and noiseless. The very stable two rail WhispahTM Linear Slide is ideal for linear motion applications that must be non-contaminating to its environment such as medical equipment, pharmaceutical manufacturing systems, and food processing equipment, or operate in harsh environments such as ceramic tile wet saws, welding systems, caustic wash downs, and outdoor (all-weather) applications.

The light weight WhispahTM Linear Slide is available in two sizes. The WSP 1 Twin Rail System features a 4.00 in. long x 5.50 in. wide table with a bearing centerline to centerline measurement of 2.125 in. For greater load and higher stability the WSP 2 Twin Rail System features a 6.00 long x 7.00 in. wide table and a bearing centerline to centerline of 2.906.

The low profile WhispahTM 1 Linear slide can handles vertical loads (Co-ax) to 150 lbs and side loads (Co-rad) to 75 lbs. WhispahTM 2 Linear slide can handles vertical loads (Co-ax) to 225 lbs and side loads (Co-rad) to 125 lbs. Both WhispahTM Linear slides are available in lengths to 120 in. The precision aluminum two rail extrusion has a Hardcoat finish for long life, and each rail is hollow to allow for a water or air line and wiring. Predrilled mounting holes make integration into new or existing systems easy. It is a low profile system however there is room to easily mount a pneumatic cylinder or electro-mechanical linear actuator to operate the slide.

Founded in 1976, LM76 has been a leading designer/manufacturer of linear bearings, slides and linear motion systems. LM76 is renowned for its industry leading Minuteman Teflon® Composite linear bearings. LM76 is a leading supplier of precision linear shafting: RC60, 300 Series Stainless Steel, and ceramic coated aluminum shafting. LM76 also offers several FDA/USDA compliant linear bearings and slides for the food processing, pharmaceutical, medical, and packaging industries.

For additional information contact Mike Quinn at: LM76, 140 Industrial Dr.

E. Longmeadow, MA 01028; Telephone: 413-525-4166, Fax: 413-525-3735 or E-Mail: [email protected] or visit the Web site at: http://www.lm76.com.

-----

Subscribe now to Laser Focus World magazine; it's free!