Variable spot sizes are nothing new. But a family of zooming optical systems developed by a visiting scholar at Stanford University offers a dramatic improvement in the ability to change the optical parameters of a laser beam in a controlled manner. The device could have significant implications for beam-delivery systems used in cosmetic-laser applications in dermatology, dentistry, and even ophthalmology.

Dubbed VariSpot by its inventor, George Nemes, the optical system is a zoom-type telescope and focusing system that provides a round spot with a continuously adjustable diameter at a fixed working distance. Typical spot diameters using VariSpot range from 0.05 to 20 mm, while fixed working distances range from 25 to 1000 mm.

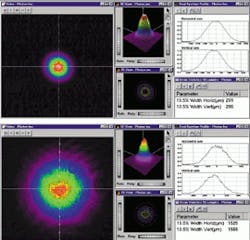

In fact, VariSpot's broad range of spot diameters and working distances are what differentiate it from existing beam-delivery systems for medical and industrial lasers (see figure). Traditional variable-spot approaches feature either a fixed spot at a given distance or a complicated system to change that spot size in a narrow range (1.5 to 3 times), which often also requires changing the working distance. VariSpot simply changes the spot size by rotating a ring (either continuously or in steps) while maintaining a consistent working distance, eliminating the need for any other refocusing or adjustment.

The total laser power transmitted through the device remains constant for all spot sizes.

In addition, the dynamic range of the VariSpot is much broader than existing approaches—perhaps even more than necessary for most applications, according to Nemes. Thus, VariSpot can be used with the same laser for a larger number of applications than a conventional telescope/focusing system, enabling a broader range of power densities at the target.

Works with any laser

VariSpot can be designed around any kind of beam-delivery system and any kind of laser, from CW to pulsed (all time scales except femtosecond lasers) and at any wavelength (UV, VIS or IR spectral range). It can also be developed for a free space or for a fiber-coupled laser. VariSpot, or the beam delivery system based on it, can be attached either directly to the laser or as a handpiece to a fiber delivery system. The device itself is cylindrical in shape and ranges in size from 5 mm in diameter and 50 mm in length to about 30 mm in diameter and 300 mm in length, depending on the design.

"This implementation is laser-specific and, for the same laser, user-specific," Nemes says. "Different designs (but using the same general optical diagram) are required for different lasers, and even for the same laser, the design might be different depending on the application. The specific laser parameters and the application dictate the quality and size of the optics, which in turn determines the price of the device."

VariSpot features three operating modes, each having several possible design configurations: focus mode, image mode, and projection mode. Focus mode offers the smallest spot size and also the largest ratio of maximum-to-minimum spot size or dynamic range (100 to 400 times). Image mode has a relatively smaller ratio (5 to 20 times) and replicates the input beam intensity profile at the target plane (such as a uniform beam profile, which is optimum for most medical applications). Projection mode is intended for large-screen, adjustable-size image projectors, not for medical or industrial applications.

Nemes has identified several potential medical applications for the VariSpot, particularly those requiring a controlled laser irradiation of a surface, such as hair removal, tattoo removal, or skin resurfacing. Some existing medical lasers have as the final optical attachment a handpiece that allows a certain spot size at the target; in most cases, these lasers require a different handpiece for each spot size used. In contrast, a single handpiece containing a VariSpot system could be used in place of several such different handpieces.

Nemes is commercializing VariSpot through ASTiGMAT (San Jose, CA), a company he founded in 1999. He is currently interested in establishing OEM and codevelopment relationships. He is also looking at developing related products, including short-length, high-magnification (10Xand 20X) telescopes for lasers and instruments for measuring laser beam characteristics (similar to beam profilers) that use unconventional optics.

"The total number of combinations of laser parameters and types of applications is quite large, and I estimate that tens of different designs (and products) are potentially available using the VariSpot principle," Nemes says.

About the Author

Kathy Kincade

Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.