Portable Microscopy/Optics Innovations: High-performance, low-profile microscopy

Ultra-compact objectives and thin filters are enabling advanced, field-portable microscopy systems ready for a whole host of applications.

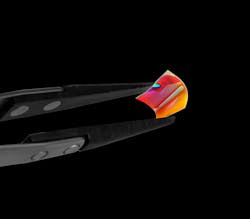

Recent technology advances have brought advanced capabilities to remote areas. For example, compact lab instruments enable clinicians to screen and diagnose patients far from any medical facility, while handheld environmental monitors provide information to speed precautionary and remedial responses in the field. And although microscopes have historically been large, fragile, and sensitive to misalignment, state-of-the-art design and fabrication techniques now make it possible to produce high-performance portable microscopy systems. Miniaturized optical objectives and extremely thin filters can significantly reduce the size and weight of such systems, enabling designers to create advanced, field-portable equipment for medical and environmental monitoring applications (see Fig. 1).

Both accuracy and rapid response are key to the portability equation. Take water quality monitoring, for example. It is risky to use a water source when its safety is in question, but cutting off access to the supply is expensive. A microscopic assay may ensure accuracy, but it typically requires field collection of a sample that is sent to a lab with appropriate equipment, leading to delayed response time. So, quick, accurate evaluation of chemical, biological, and impurity characteristics would be greatly beneficial.

A similar scenario exists for such clinical applications as testing for malaria, a disease resulting from a mosquito-borne parasite that induces morphological changes in red blood cells. Imaging of the erythrocytes enables accurate diagnosis, but carrying a laboratory microscope to remote tropical areas is impractical. The alternative is to return samples to the lab, again delaying critical diagnoses.

Beyond such biomedical applications, microscopic examination can be extremely beneficial in manufacturing. But in a space-constrained production line, integrating the ability to magnify welding defects such as voids and spatter is often out of the question. Thankfully, designers are increasingly able to produce low-profile, high-accuracy systems that are also durable.

Big things come in small packages

Modern ultra-compact microscope objectives bring high magnification and high performance to space- and weight-sensitive applications (see Fig. 2). Their form factor, as small as 25 mm in diameter and 11 mm in thickness (roughly the size of a small stack of quarters), is achieved by using small 4- to 7-mm-diameter lens elements and a slightly larger 8- to 15-mm-diameter front element with a short focal length, sharp radius of curvature, and small f/#. Simplifying the objectives’ mechanics allow them to be miniaturized further, so they will have a fixed focus, small baffles, and no adjustable apertures.Such objectives tend to not be planar, meaning resolution and contrast will be better on axis in the center of the field of view, and there will be around 5–10% contrast deterioration on the edges because of field curvature. However, there is an advantage to being non-planar: these objectives can resolve images on a large, full-frame image sensor, which is beneficial for many applications, including cell detection and microscopic fault analysis (but not appropriate for applications requiring beyond diffraction-limited performance).

Ultra-compact objectives also tend to be finite-conjugate, which means they can be turned into modular zoom lenses by varying the sensor position with respect to the objective’s entrance pupil. Adding extension tubes changes the objective’s magnification, allowing one objective to be used in multiple different scenarios. With some precise translation stages or actuators, a researcher could easily write a script or algorithm to achieve a modular zoom microscope. (By contrast, infinite conjugate objectives are difficult to get to the same level of miniaturization without inducing more severe aberrations.)

These capabilities enable the potential for completely new form factors. The current archetype of portable technology is the cell phone, and a microscope objective with a short optical path length that weighs only a few grams enables super-compact designs that interface with smartphones. Phone-based instruments are now used to rapidly detect morphological changes associated with the West Nile and Zika viruses, for instance. But while phone-based microscopy approaches have typically required a great deal of programming, computing power, and time to compensate for spherical aberrations in the optics used (see “Hardware vs. software”), super-compact objectives provide high-quality imagery without algorithmic adjustments or compensation.

Hardware vs. software

With a goal of achieving lower profiles for greater portability, developers are attempting to miniaturize every aspect of their systems. Some, for instance, have pursued “computational microscopy,” involving the use of algorithms to replace optics. And while algorithms definitely have their place in optical systems, it’s important to recognize their limitations.

For one thing, algorithms require processing time, whereas optics operate in real time. Adding computing power can help speed an algorithm’s operation, but even that won’t get you real-time operation—although it may get you a bulkier system.

A related issue is reliance on an external operator. And in the case where your data will be sent to a remote processor (which will slow operations further), security and fidelity factor in. How do you know your data is not corrupted? For that matter, how do you know that your algorithm is working properly?

The more you need speed, accuracy, and reliability, the more you need high-quality optics.

Advantages for applications

With any enabling technology, new applications emerge as designers become aware of the new capabilities. It is easy to imagine a lightweight, robust imaging system as the heart of a drone-mounted sensor array, with applications limited only by imagination. And in portable entertainment, where both handheld displays and AR/VR applications are growing rapidly, an ultra-compact microscope could enable entirely new options. The overlap between entertainment and education is also rich with possibility, including classroom-scale systems that enable easy integration of real-time microscopy images into the curriculum. And while fluorescence detection of adenosine triphosphate (ATP) is now done macroscopically in the food service industry, pharmaceutical production, and in hospital rooms, shrinking to microscopic scales promises to boost the accuracy of such inspections.

With growing interest in rapid-response and in situ measurements, the range of applications for highly compact microscopy systems will surely continue to grow, and yet-unanticipated applications will leverage the advantages of compact, lightweight, and robust microscope objectives and filters.

About the Author

Cory Boone

Cory Boone is technical marketing manager at Edmund Optics. He is responsible for managing the creation of technical marketing content, including application notes, published articles, web copy, email campaigns, video scripts, trade show materials, case studies, and other marketing literature. He plans the company’s technical content strategy and acts as the technical voice of the marketing department. Cory is also active in educational outreach and spreading general awareness of the optics industry. He received a B.S. in Optical Sciences and Engineering along with minors in Math and Material Science Engineering from the University of Arizona.

Stephan Briggs

Biomedical Product Line Engineer, Edmund Optics

Stephan Briggs started with Edmund Optics as an intern while pursuing his degree in biomedical engineering at Drexel University with a concentration on tissue engineering and biomaterials. Following graduation, he joined as Biomedical Engineer, working directly with EO’s life sciences customers. With a solid understanding of processes and technologies, he helps researchers and system builders accomplish their goals with correct application and integration of components and subsystems. He has authored numerous articles on a range of topics of interest to life scientists, including light sources, optics, individual and combined imaging approaches, and cost-efficient design options.