SPECIALTY FIBERS: Specialty fibers solve tough spectroscopy problems

BRIAN FOLEY

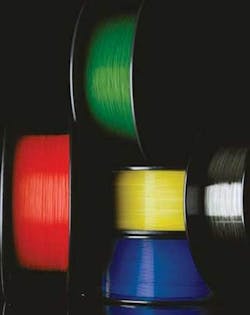

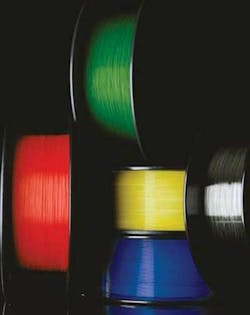

Specialty fibers can extend the range of spectrometers, providing the benefits of spectroscopy in both the lab and the field. They offer a method for moving light to the spectrometer in the many applications in which it is impractical or inconvenient to place materials into a sample chamber. But to do this, the fibers must have several specific properties. Depending upon the application, these properties can include the ability to carry light at a wide range of wavelengths-from the near-ultraviolet (UV), through the visible, to the infrared (IR)-with low loss, while being tough enough to survive challenging environments (see Fig. 1).

While such field applications as beef tenderness estimation, pharmaceutical safety checks, and military munitions assessments pose specific challenges, specialty fibers are also extending spectrometry in the lab where fiber probes can enter chemically and physically hostile environments.

The problem for spectroscopy

Spectroscopy acts like chemical fingerprinting, allowing quantitative and qualitative materials analysis. And the development of compact spectrometers-by Ocean Optics (Dunedin, FL), among other companies-has broadened the capability of these instruments to work beyond the lab. Spectroscopy is nondestructive and can offer fast results. Users have developed a number of different types of spectroscopy methods including absorption, reflectance, and Fourier-transform IR (FTIR), each of which places different requirements on the fibers.

Flexible fibers coupled to the spectrometers extend the reach of the instrument in many applications when the size or shape or location of a sample does not allow it to be easily placed in a cuvette. The flexible fibers make portable systems much more useful in the field. If the sample is in a hot, corrosive, or otherwise challenging environment, or if it is shaking or vibrating too much for the spectrometer to handle, then robust fibers can provide a way to get the signal out.

Water content

The hydroxide (OH) or water content of silica fiber changes its spectral performance: fibers used for UV spectroscopy contain a relatively high percentage of OH, around a few thousand parts per million. Fiber used in the mid-IR region, however, needs to be very “dry”-with an extremely low OH level of only a few parts per billion (See “Why telecom fiber won’t do: apples and oranges,” p. 85). By manipulating the OH content, silica fibers can be optimized for carrying light over wavelength ranges from 160 to 1200 nm in the UV as well as from the edge of the visible at 350 nm, through the visible, and up to the near-IR region at 2400 nm (see Fig. 2).

By controlling the chemistry of the preforms from which the fiber is drawn, the OH content of the fibers can likewise be controlled. Preform control also allows control of the fiber numerical aperture (NA), which dictates the amount of light that can easily pass through the fiber. Telecom fibers tend to have NA values of around 0.22; CeramOptec has produced fibers with NA values as high as 0.53. Fibers can also be customized with nonsilica cladding (such as hard plastic cladding), or for particular performance characteristics including operation at very high (+380°C) or low (-190°C) temperatures.

High NA

Some spectrometers, such as the portable near-IR (NIR) reflectance spectrometers made by ASD (previously Analytical Spectral Devices of Boulder, CO), use fiber internally as well. Tom Brown, director of sales and marketing at ASD, says that the company uses a hybrid approach, splitting the incoming signal among three spectrometers to cover a range from 350 to 2500 nm. Shorter wavelengths are limited to 2 m lengths at most, while visible wavelengths may have longer fibers. Often, a particular application dictates how close the spectrometer can be placed to the sample.

High numerical aperture is extremely important for reflectance spectroscopy applications. “Reflectance spectroscopy demands that you have a very efficient system,” says Brown. “Every component needs to be tweaked to make the most of the light that’s there.” In addition to using fibers with high NA, the company’s equipment also incorporates precollecting optics, to gather as much light as possible to the fiber.

Another benefit of high-NA fibers is that the fiber can be thinner while still maintaining highly efficient coupling. Smaller fibers are more flexible, more resistant to fatigue, occupy less space, and weigh less. Although a higher NA beam will be more divergent, a smaller fiber diameter will initially project a smaller spot near the fiber end, so close-coupled instruments should not suffer from the higher NA.

Field spectroscopy—fast

Some real applications for ASD include portable NIR reflectance spectrometry as a secondary method-providing “ground truth” that can be compared to either remote sensing (such as satellite data) or chromatography or x-ray testing in a lab later on. The battery-operated instruments can perform online real-time measurements for most anything organic, including pharmaceuticals, food, paper or wood, as well as for mineral products in mining applications. Because a spectrum can be gathered in tenths of a second, this performance can allow the sampling of every product passing through a process line, for example, in measuring beef tenderness at meat-processing plants.

Tenderness is just one aspect of grading beef in real time. The absolute test is shear-force measurement, but that requires cutting a piece of meat, aging it 14 days, cooking it, and then measuring the force required to cut it. By that time, the beef has long since been shipped to supermarkets. It turns out that tenderness is fairly complex and not just a matter of the starting material. As anyone who has ruined a good steak by overcooking, or improved the tenderness of meat by marinating knows, treatment also matters. Folklore suggests that more marbling (the mixture of fat with meat) produces more tender meat, but it turns out that marbling is not necessarily connected to tenderness.

To predict beef tenderness, some customers have developed a test that uses NIR reflectance spectroscopy. The system can be mounted above a conveyor belt and enclosed in a hardened case, but the external fiber probe must also be protected. CeramOptec was able to provide a hardened fiber assembly that can survive the harsh chemical environment necessary for cleaning, while still providing flexibility (see Fig. 3).

null

Process control

Many industrial processes take place in brutally harsh conditions, such as studying the chemical composition inside a reaction chamber during a particular process. Mettler Toledo (Columbus, OH) offers lab-based FTIR absorption spectroscopy equipment to the pharmaceutical, chemistry, and polymer industries. A mid-IR-transmitting fiber is incorporated into a very tough probe that can withstand low or high pH temperatures as hot as 300°C, and pressures as high as 5000 psi.

Unlike the beef tenderness example, this instrument does not use silica fiber. Instead, it incorporates a silver halide fiber that transmits light from 4 to 16 µm with low attenuation. Made from a nonhygroscopic material that does not absorb water easily, this fiber offers a working temperature range from -40°C to +110°C and has a minimum bend radius of 100 times the diameter of the fiber.

Previous methods for analyzing spectra from these environments use mirrored conduits, or chalcogenide fibers. But silver halide fiber is thinner and more flexible than the alternatives. It also provides about five times the sensitivity of chalcogenide fiber, says Brian Wittkamp, RTA-East market manager for Mettler Toledo Autochem (Columbia, MD), which allows customers to measure lower concentrations of material in a reaction vessel. In addition to use in the lab, the instruments can be used in production applications (see Fig. 4).

Spectroscopy fibers are far more than just telecom-fiber preforms drawn to nonstandard diameters. By controlling the entire process, from creating the preform to incorporating the fiber into an assembly, specialty fibers can meet the challenges of a variety of spectroscopy applications.

BRIAN FOLEY is vice president of engineering and manufacturing for CeramOptec Industries, 515A Shaker Rd., East Longmeadow, MA 01028; e-mail: [email protected]; www.ceramoptec.com.

Why telecom fiber won’t do: apples and oranges

Telecommunications is the largest market for optical fiber, and consequently, silica fiber optimized for this application has become very inexpensive. You cannot expect to use telecom fibers as spectroscopy fibers, however, because they are like apples and oranges. And just as apples and oranges are priced differently, the cost of specialty fibers doesn’t bear any resemblance to the pennies-per-meter cost of telecom fibers: the market volume for specialty fibers is nothing like the high-volume telecom market; every fiber is, effectively, custom-made.

Spectrometry fibers have requirements that are different from those of telecommunications fibers. Many spectroscopy applications benefit from a fiber with a larger numerical aperture (NA) and spectral performance that is different from those of telecommunications fiber. So how are the transmission and/or thermal properties of fibers optimized for spectroscopy? Many specialty-fiber products are special only in terms of size: companies buy standard preforms and then draw the fiber to the sizes required, but do not otherwise change the chemistry. By controlling the chemical makeup of the preform, CeramOptec is able to offer better performance by changing both the NA (by changing the cladding doping) and the spectral performance (by changing the water content).

Silica is a good material for fiber in general, in terms of its optical and thermal properties. It can be produced with ultrahigh purity and it has little absorption across a wide range of wavelengths from about 200 nm to over 2400 nm. But sometimes other solutions are more appropriate. For some high-NA solutions, CeramOptec uses hard plastic rather than silica for the fiber cladding. And for mid-IR solutions, silver halide fibers are offered for process-control applications.