Waveguide lasers capture spectra in one shot

Small, simple, rugged, and inexpensive—all these are desirable qualities for an optoelectronic device or instrument. Now, researchers at Kyushu University (Fukuoka and Kasuga, Japan) have brought these attributes to laser spectroscopy. In this field, the traditional light source is a tunable laser: a liquid-dye laser or, more recently, a solid-state tunable source such as a Ti:sapphire laser or an optical parametric oscillator. Basing their light source on waveguide technology, the Kyushu University group has created an array of miniature multiwavelength dye lasers that span a spectral range simultaneously.

The approach is called "digital spectroscopy" by the researchers, in contrast to traditional wavelength scanning, or "analog spectroscopy." The laser array's gain medium is a slab of solid polymer infused with Rhodamine 6G dye; each individual laser is defined by a 4-µm-thick waveguide structure fabricated by ultraviolet lithography. The cavity mirrors are distributed feedback (DFB) gratings also created via lithography, with each DFB structure of slightly differing period to create a range of wavelengths. The entire polymer slab is side-pumped with a frequency-doubled Nd:YAG laser that has a pulse duration of 5 ns and a repetition rate of 10 Hz.

null

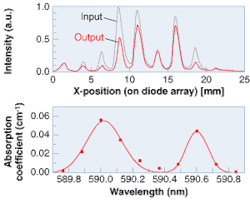

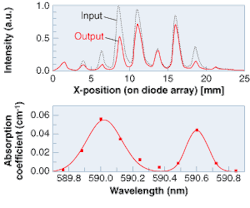

With use of a photodiode array, all spectroscopic data can be gathered in a single shot of the pump laser. In one experiment, nine 15-mm-long waveguides were fabricated on a chip with output wavelengths ranging from 589.8 to 590.7 nm—a range that covers the D1 and D2 sodium absorption lines. The results of a test on a sodium-vapor cell clearly show the lines (see figure).

The lifetime of the dye-laser array before the array output decreases to half its original value is about 5 × 106 shots. To increase laser lifetime, an array that includes redundant laser waveguides could be made, allowing a shift to an unused laser whenever output decreases beyond a certain level. Other improvements are being considered. "I'm thinking to broaden the spectral range," says Yuji Oki, one of the researchers. "To do this, we need to integrate waveguides doped with different kinds of dyes on a chip. In the future, I'd like to produce disposable and spectrally universal dye-laser chips pumped by a small laser unit via optical fiber." Such a device would be palm-sized, stable, and fast, with picosecond measurements possible.

REFERENCE

- Yuji Oki et al., Opt. Lett. (Aug. 15, 2002).