783-nm DFB laser emits 200 mW in single mode

Semiconductor distributed-Bragg-reflector (DBR) and distributed-feedback (DFB) lasers in the 770- to 860-nm wavelength range are useful for exciting and cooling cesium or rubidium atoms for atomic clocks, Raman spectroscopy, and even as primary sources in frequency-conversion systems. Especially for the last purpose, such lasers should supply high power in a narrow spectral interval while at the same time providing high beam quality.

Indium phosphide (InP)-based DFB and DBR lasers have matured, driven by telecommunications applications in the 1300- and 1550-nm spectral bands. To obtain shorter wavelengths, however, gallium arsenide (GaAs) technology with aluminum (Al), In, and P alloying must be used, which imposes technological complications when, in addition, DBR or DFB structures have to be generated. Alloying must be used to obtain the desired energy bandgap and permittivity profiles. Complications arise from the fact that Al has a high affinity to oxygen and that a surface consisting of an oxide cannot be overgrown with a semiconductor.

A research group at Ferdinand-Braun-Institut für Höchstfrequenztechnik (Berlin, Germany) has now succeeded in manufacturing a DFB laser that is capable of emitting 200 mW in a single transverse and longitudinal mode at 783 nm.1 The researchers preferred a DFB over a DBR configuration because the latter shows longitudinal mode-hopping when tuned by the injection current, whereas DFB cavities (where the permittivity corrugation is applied fully along the gain medium) allow continuous tuning, as required by most spectroscopic applications.

The DFB laser wafer was grown by low-pressure metal-organic vapor-phase epitaxy in two steps. The first step consisted of fabricating the n-AlGaAs cladding and waveguide, the GaAsP active quantum well (QW), the p-AlGaAs waveguide, the first part of the p-AlGaAs cladding, and an InGaP/GaAsP/InGaP layer sequence in which the second-order grating was formed by holographic photolithography and wet chemical etching. After surface cleaning, in the second step the remainder of the p-AlGaAs cladding and a p-GaAs contact layer were grown. The lateral confinement of the beam was achieved by a ridge waveguide. The cavity length was 1.5 mm and the front and rear facets were anti- and high-reflection coated, respectively. Layer thickness was controlled to a 1-nm precision.

At the desired wavelength and with the structure used, a first-order grating would require a period of 118 nm, which cannot be realized with the holographic equipment used. Hence, a second-order grating with a period of 236 nm was chosen. However, in this case, the duty cycle of the grating had to be carefully selected to 0.25 (or, equivalently, to 0.75) to ensure that the coupling coefficient of the grating be sufficiently large and to reduce the unwanted surface radiation.

The device was mounted on a temperature-controllable heat sink operating at 25°C. Lasing started at 29-mA threshold current with a slope efficiency of about 1 W/A. The authors attribute the high efficiency to the small coupling coefficient (low loss) of 2 cm-1 realized by the Bragg grating, yielding a coupling coefficient times cavity length of 0.3. The coupling coefficient is a measure for the coupling strength of the forward- and backward-propagating waves. The larger the coupling coefficient, the larger the effective reflectivity of the grating. Hence, like in a Fabry-Perot laser, the threshold current and the slope efficiency increases with decreasing coupling coefficient.

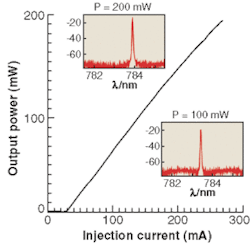

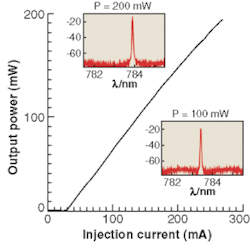

The polarization was greater than 92% TM over the full operating range up to 200 mW, no beam steering occurred, and far-field full-width half-maximum angles were 8° and 21°, respectively, with a near-Gaussian beam shape. The light-current characteristic and two spectra for the laser were measured at 100- and 200-mW output power; the peak wavelength changes by about 0.5 nm (see figure). The side-mode suppression is better than 50 dB, indicating complete suppression of the second Bragg and Fabry-Perot modes. The tuning rate varies nonlinearly with power, but almost linear tuning is achieved by temperature control of the heat sink; however, the power drops slightly with increasing temperature.

In principle, by using this technology, lasers can be designed for different wavelengths in the range of 760 to 980 nm, each continuously tunable over a few nanometers with a normalized bandwidth of less than 10-7. Because of their precision and small size, such lasers may become valuable tools for atomic clocks and uses onboard spacecraft.

REFERENCE

- H. Wenzel et al., Elect. Lett. 40(2) (2004).