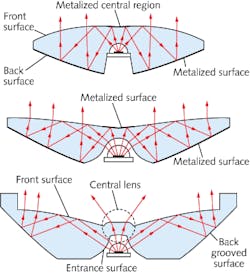

An RXI optical element, so-called because it produces ray deflections by refraction (R), reflection (X), and total internal reflection (I), can be very efficient at collimating or concentrating light with a high numerical aperture for purposes not requiring a good image (such as collimating the light from an LED). Portions of most RXI elements require a metal coating for reflection (see figure, top and center), which raises the manufacturing cost. Now, a group from the Universidad Politécnica de Madrid (Madrid, Spain) and LPI (Altadena, CA) has created a plastic RXI collimator for LEDs that does not require any metalization (see figure, bottom).

The trick was to replace the normally metalized surface with a surface containing 60 small vertical grooves having a 90° bottom angle for retroreflection of light. The light from medium to high angles from the LED is collected and collimated by the RXI. The collimator also contains a central lens that collects low-angle light from the LED and spreads it over an angle of 10° to 30°; because this RXI is intended for use in flashlights, this angular spread provides a smooth, controlled, color-mixed intensity pattern for background illumination. Testing with LEDs by Cree (Durham, NC) confirms that the new device is more uniform and less sensitive to LED nonuniformities than previous devices, allowing easy LED dimming (LEDs change uniformity as they dim). Contact Dejan Grabovičkić at [email protected].

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.