Laser technologies could improve cochlear implant design

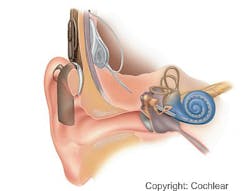

Research groups at Laser Zentrum Hannover EV (LZH; Hannover, Germany) are developing laser-based technologies for improved insertion techniques and exact fitting of cochlear implants (CIs) in the inner ear, as well as better quality for residual hearing.

The Surface Technology group is currently working on a process to simplify the operation and improve the insertion technique of the electrode into the cochlea. To accomplish this, they are using the special properties of nickel-titanium shape memory alloys (NiTi-SMAs) in manufacturing the CI electrodes. By heating the electrode, the material "remembers" the form or shape it was manufactured in, thus allowing specific movement and fitting of the electrode. While laser melting is used to form the NiTi-SMA into a highly individual implant, the material's special characteristics can be used to insert the implant into the cochlea without damaging the basilar membrane.

A second approach is also being used to optimize the characteristics of CIs: The Laser Micromachining group is working to improve the surface of implants by using laser structuring. By using a femtosecond laser, the platinum electrodes can be structured in a special way. Special nanostructures, looking very rough when magnified, can be manufactured, which reduce attachment of connective tissue and improve interaction with the nerve cells. Simultaneously, nanostructuring decreases frequency-dependent electrical resistance, meaning less energy is needed. But the structures must be made on an implant measuring only 300 µm in diameter and with a curved surface. At the moment, the group is working to provide these complex structures on a very small scale.

LZH is presenting the results of their work at the Hannover Messe 2012 show (Hall 17, Stand C55), being held this week from April 23-27.