Swiss timepieces reach new heights with 3D glass microfabrication

Swiss watchmaker Ulysse Nardin has launched the FREAK neXt concept watch, highlighting the company’s expertise in glass components fabricated by FEMTOprint (Muzzano, Switzerland). The FEMTOprint 3D printing platform combines submicron precision optics manufacturing with high aesthetical characteristics, blending fluidic, optical transparency, and mechanical functionalities into single monolithic devices.

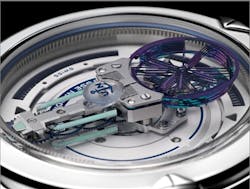

In addition to the FEMTOprint 3D glass minute hand and the glass bridge with built-in shock protection for the balance wheel on the predecessor InnoVision Two watch, the FREAK neXt presents a trapezoidal-shaped glass bridge for a new carousel baguette movement with a flying 3D oscillator that improves on the traditional balance spring design of the 17th century. The glass bridge is framed by four 8.34-mm-long glass tubes with 400 µm diameters (inlets of 200 µm) filled with superluminescent strontium aluminate pigment to illuminate the tubes in the dark. The logo, in its characteristic marine blue, engraved in the glass monolithic lens is 5.0 mm in diameter and 1.95 mm in height, and presents multiple heights (features down to 130–180 µm deep), planar and convex shapes with different angles and radii, paintings for decorations, and selective surface polishing with surface roughness <20 nm. Reference: www.femtoprint.ch/news-freaknext.About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.