Hollow-core fiber: The next leap forward for global network infrastructure

As the digital world barrels toward an era powered by artificial intelligence (AI), cloud computing, and next-generation mobile networks, the invisible threads linking our lives, the fiber-optic cables underpinning the internet, are beginning to fray at their limits. At the center of a quiet technological revolution lies hollow-core fiber (HCF), a development that may redefine how data is moved around the globe—and affect everything from hyperscale data center operations to long-distance financial trading.

Rethinking light’s journey: What is hollow-core fiber?

For decades, glass-core optical fibers have carried the world’s information. But their physical properties impose hard limits on performance. Signals attenuate with distance, speed is capped by glass’s refractive index, and nonlinear effects can garble high-density traffic. This is where HCF comes in as a new breed of fiber that guides light not through solid glass, but through a core filled with air.

This innovation sounds simple: Why not use air, through which light travels faster and with less distortion? But confining and directing the light beam with high efficiency was, until recently, a major scientific challenge.

Perhaps the most promising HCF technique uses antiresonant reflecting (ARR) fibers, harnessing fine glass membranes to bounce light effectively down the core. This approach was developed by Lumenisity, a spinoff from the Optoelectronics Research Center at the University of Southampton, U.K., which was recently acquired by Microsoft.

In another U.K. development, University of Bath researchers created a mathematical model that explains how antiresonant HCFs can guide light to keep data loss ultralow. This work enhanced our understanding of why some air-filled fiber designs work more efficiently than others.

Lab bench to data center: The promise of HCF

Researchers and industry heavyweights are already trialing hollow-core technology in real-world settings. In perhaps the most high-profile experiment to date, Microsoft is using HCF cables in its Azure data centers and reports an increase of up to 47% in data speeds along with noticeably lower latency, which are key metrics for advanced AI and cloud services.

Across the globe, China’s Yangtze Optical Fiber and Cable (YOFC) recently set new records by pushing a single-wavelength signal at 1.2 terabits per second over more than 10 km (6.21 mi), and by field-deploying a system that transferred 100.4 terabits per second across a 20-km (12.43-mi) span. The tests were a clear indicator that HCF is not just a laboratory curiosity, but a technology ready to face the rigors of telecom-grade deployment.

Why all the excitement? HCF significantly reduces latency because light moves through air much faster than through glass. It also suffers less from the signal-damaging nonlinearities that hamper traditional fiber, which makes it ideal for high-powered, error-free transmission. This is exactly what tomorrow’s AI clusters, financial trading floors, and even undersea internet backbones require. Notably, virtually all record-setting experiments have focused on performance at or near 1550 nm, which cements this wavelength’s importance for the future of HCF networks.

Wavelength matters: The case for 1550 nm

Wavelength choice is critical in optical communications, and 1550 nm (C-band) is the focus of development. It exhibits minimal attenuation (typically between 0.1 and 0.2 dB/km), supports high data rates, and is compatible with both legacy and next-generation optics. Chromatic dispersion is manageable at 1550 nm, which helps maintain signal integrity and speed during transmission, especially for dense wavelength division multiplexing (DWDM) systems used for high-capacity networks.

HCF networks, operating at 1550 nm, enable direct integration with modern transceivers, multiplexers, amplifiers, and existing network infrastructure. Infrared (IR) at this wavelength is also inherently safer for free-space transmission because it is less likely to cause eye injury. These features make 1550 nm not just a technical convenience, but a foundational element to determine how well HCF can be deployed across vast networks.

1550-nm IR sensors are indispensable for networks

IR sensors in the form of indium gallium arsenide (InGaAs) avalanche photodiodes offer high sensitivity and low noise at 1550 nm, which allows HCF to fully leverage the reduced latency and higher bandwidth theoretically possible. By using this industry-standard wavelength, new installations of HCF can interconnect cleanly with legacy optical transport network (OTN) gear and DWDM systems to maximize both their immediate and long-term value.

Using 1550 nm also ensures compliance with global laser safety standards, which is especially important when installing or maintaining large-scale network links such as those crossing cities or running beneath oceans. Both public and private sector networks benefit from this safety margin, which significantly reduces risk during fieldwork and routine monitoring.

Hurdles to mass adoption

The journey from breakthrough to industry mainstay is rarely smooth. Manufacturing HCF at scale is costly, because the advanced structures demand precision fabrication and strict quality control. The fiber itself is lighter and more fragile than its glass-core counterpart, which poses extra challenges for installation teams working within harsh or remote settings. Fusion splicing, which is essential for joining fiber runs without excessive loss, remains a sticking point. But progress is being made with specialized splicing techniques and ruggedized cable designs.

For network operators, the numbers will be crucial. HCF promises lower operational expenditure since less energy is needed for signal boosting and error correction, but these long-term savings must be weighed against substantial capital investment.

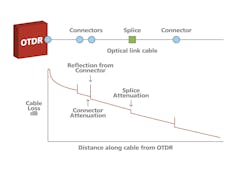

Testing and troubleshooting: IR sensors and the evolution of OTDR

Routine network monitoring is evolving rapidly because optical time domain reflectometry (OTDR) must adapt to the unique properties of HCF. OTDR is the industry’s principal tool for fault location, fiber characterization, and loss mapping. Its effectiveness rests on the use of IR light at 1550 nm. This wavelength penetrates long distances with minimal scattering or absorption, which gives engineers detailed insight into network integrity.

But HCF dramatically reduces Rayleigh backscatter by funneling light through air rather than glass. The drop in backscattered signal, often by 40 dB or more, makes it more difficult to locate faults or measure loss with traditional OTDRs. New generations of OTDR instruments will rely on ultrasensitive IR sensors at 1550 nm, matched with advanced digital filtering and noise rejection. These upgrades will extend detection ranges, isolate subtle defects, and allow for complex calibration routines like dual-ended measurements or time-gating, which are essential for the accurate evaluation of HCF networks.

The ubiquity of 1550 nm also means field technicians can continue to use familiar test sets, accessories, and safety protocols as they work on this cutting-edge technology. Companies are now standardizing on 1550-nm sources and detectors for both network operation and troubleshooting to ensure continuity between legacy equipment and next-generation HCF deployments. This practical compatibility accelerates uptake and minimizes training costs, both of which are critical for network operators under pressure to scale swiftly.

Global interest grows

Microsoft, China’s YOFC, and others are working to commercialize breakthroughs in the development of HCF by rolling out pilot projects and refining manufacturing methods.

Standardization will be the next big battleground. Industry groups and global standards agencies are racing to agree on benchmarks for performance and interoperability, which will open the doors for mass adoption and a healthy, competitive supply base.

Looking further ahead, projections for HCF are bold. Engineers now believe it is plausible that ultralong-haul HCF cables could span more than 10,000 km (6,213 mi)—and potentially revolutionize transoceanic internet links by slashing delays and multiplying capacity.

The stakes are significant: HCF offers tantalizing improvements in speed, capacity, and signal fidelity. The path to maturity, however, will be shaped by economic, technical, and operational realities. If the hurdles can be overcome, and current momentum suggests they can, HCF could soon become the backbone for 6G, quantum communications, and the data-driven, AI-powered applications of the future.

About the Author

Christian Rookes

Christian Rookes is VP of marketing at Phlux Technology, a manufacturer of avalanche photodiode (APD) infrared sensors based in Sheffield, U.K. He has more than 25 years’ experience in technical marketing in semiconductor and optical communication fields. Rookes holds a BSc in Engineering and Physics from Loughborough University and an MBA Essentials Certificate from the London School of Economics. He holds two patents, including one related to impedance matching for laser diode circuits.