Whole-fiber sensing method uses light to generate acoustic sensing signal

Researchers have developed a new fiber-optic-based chemical sensing method that uses light inside a whole fiber (no etching, no tapering) to induce sound waves outside it, providing indirect information about what surrounds the fiber. By overcoming a significant limitation of existing fiber-optic sensors, the new method could improve sensing capabilities for a wide range of applications, including industrial processes and remote detection of chemicals.

"A fundamental restriction that makes sensing of chemicals very difficult is that we must have overlap between light and the substance being measured," said Avi Zadok, Faculty of Engineering and Institute of Nano-Technology, Bar-Ilan University (Israel), who led the research team together with graduate student Yair Antman. "This limitation has been holding us back for many, many years in fiber sensors."

The researchers demonstrate their fundamentally new sensing method in The Optical Society's journal Optica.1 "We employ the interrelations between light and sound, and use sound as our messenger to the outside world," Zadok said.

Existing fiber-optic sensing technologies typically require the light inside of the fiber to contact the substance being measured and previously, this technology required drastic modifications such as drilling holes in the fiber or etching it down to a very thin diameter to force the light to come out. “While you can get fantastic sensitivities in these approaches, the fact that you have to go through these modifications makes it more difficult to produce these sensors and also affects their robustness,” said Zadok.

Rather than using light directly, Antman came up with the idea to use light transmitted through optical fibers to create sound waves, or acoustic vibrations, taking advantage of a phenomenon known as stimulated Brillouin scattering. And allthough stimulated Brillouin scattering is used in commercial fiber sensors today, existing sensors keep both the light and the sound waves inside the fiber. "The critical step was to look for certain mechanical behaviors that do reach outside the fiber, and take advantage of those," said Zadok. "We found that stimulated Brillouin scattering in a forward direction could be used to provide information about what is outside of the fiber."

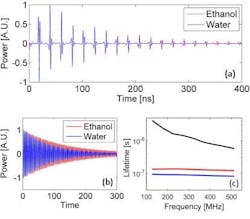

The new approach works by using optical waves that are intense enough to create an acoustic vibration that reaches outside of the fiber (see figure). These vibrations gradually decay based on properties of the substance that surrounds the fiber, providing an indirect method of sensing the chemical content of the environment. Because the light remains inside the fiber, the technique allows the use of a traditional optical fiber with no structural modifications, and the researchers only had to remove the fiber's protective plastic coating.

The researchers demonstrated their new technique in ethanol and deionized water, taking acoustic impedance measurements, which provide information about a liquid's density and the speed of sound wave traveling through the liquid. Results reproduced known values with 1% precision. They also successfully distinguished between water samples with different levels of salinity.

The technique might one day be useful for monitoring the desalinization of water, or electro-chemistry processes such as in fuel cells, or for detecting changes in the concentrations of ions or dissolved salts used in industrial chemical processes.

REFERENCE:

1. Y. Antman et al., "Optomechanical sensing of liquids outside standard fiber using forward stimulated Brillouin scattering," Optica 3, 5, 510 (2016).

SOURCE: The Optical Society; http://www.osa.org/en-us/about_osa/newsroom/news_releases/2016/using_light_to_create_sound_researchers_develop_i/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.