Integrated approach produces reliable high-power fiber lasers

High reliability in a high-power fiber laser can be achieved by adding innovations in fiber geometry to improvements in efficiency.

High-power fiber lasers promise a suite of attractive features, including small footprint, high efficiency, high reliability, low operational cost, high beam quality (often diffraction-limited), and flexibility of beam delivery. These lasers are commercially available in tens to hundreds of watts for various applications in printing, marking, and materials processing. Even higher powers can be reached through various methods of beam combining. Maintaining reliability while scaling up to high powers is important; a combination of several approaches will make this possible.

Fiber geometry

At the heart of the fiber laser is the gain medium, in the form of a double-clad fiber doped with ytterbium (Yb), erbium (Er), or other rare-earth active ions. The double-clad fiber is pumped by many broad-area lasers either in a single-emitter geometry, in bars, or in stacks. The gain medium is typically a double-clad fiber with a single-mode or a quasi-single-mode, rare-earth-doped core surrounded by an inner cladding into which high-power multi-transverse-mode light is pumped. The glass inner cladding is circumscribed by a low-index outer cladding. Such claddings are used to provide the index contrast to achieve the high numerical aperture (NA) needed to effectively couple light from the pump diodes. Another approach to achieving high NAs is to make the outer cladding from microstructured or holey glass to reduce the effective refractive index.

A fiber laser can be configured in the oscillator or amplifier mode. In the oscillator mode, a high reflector in the form of a fiber Bragg grating (FBG) or multilayered dielectric is made on one end and a partial reflector is located at the output end. In the amplifier mode, a seed signal is amplified in a single pass through the gain medium.

The oscillator can be tuned somewhat by adjusting the period of the FBG. The amplifier, on the other hand, will amplify any seed signal that is fed to the fiber laser. The seed can be a tunable laser, a pulsed laser, or other type of signal. With a judicious choice of gain fiber, the amplifier can amplify very narrow bandwidth signals effectively. The ability to amplify arbitrary waveforms will enable new applications using fiber-laser technology.

Challenges in scaling up to high powers

When the pump power is increased to make high-power fiber lasers, two nonlinear phenomena occur-stimulated Raman scattering (SRS) and stimulated Brillouin scattering (SBS). In the oscillator mode, the primary impairment to high optical power is SRS, in which the signal is inelastically scattered by the host glass to longer wavelengths. In the amplifier mode, the primary impairment phenomenon is SBS, where high-frequency acoustic waves are generated that cause variations in the refractive index, causing light to scatter in the reverse direction.

For a standard single-mode fiber, the SRS threshold is reached at about 100 W, and the SBS threshold is reached at about 1 W of power. These thresholds can be decreased by reducing the intensity of light in the fiber or by reducing the length of the fiber. The primary method of achieving this involves increasing the mode area of the fibers (large-mode-area fibers). To accomplish this and still maintain single-mode operation, however, the NA of the core must be decreased. Reducing the NA of the fiber creates a smaller difference between the refractive index of the core and cladding. Fibers with core diameters of 30 µm and NAs as low as 0.06 are available. Another method of maintaining single-mode operation is to use a bend-loss mechanism to filter out higher-order modes.

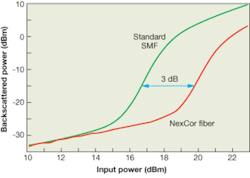

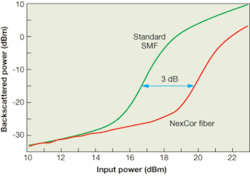

In addition to increasing mode area, other modifications to fiber design can decrease the SBS threshold. This approach has enabled a 3-dB increase in power transmitted in the fibers for access applications (see Fig. 1). An adaptation of this approach in conjunction with large mode area is being pursued for gain fiber.

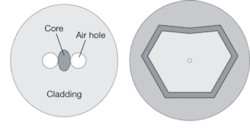

If polarized light is desired, dichroism in the form of either polarization-dependent loss or gain is required to prevent laser operation on the unwanted polarization eigenmode. Dichroism can be induced by stress rods in a manner similar to polarization-maintaining fiber or with a newer elliptical-core, hole-assisted single-polarization fiber design (see Fig. 2).

Generating and handling high pump powers

Other aspects of high-power fiber lasers are related to generation of a large amount of pump power and delivering (coupling) it to the outer core of the double-clad fiber. For example, 1 kW of output power from a fiber laser with 70% optical-optical conversion efficiency would require 1.45 kW of pump power coupled into the fiber. Because the pumps are multimode laser diodes delivering 2 to 4 W each, power from about 360 to 720 pumps must be combined to pump the gain medium. These lasers are typically individually packaged and then combined using fused-fiber couplers. Several of these pump groups are combined into a fiber bundle that is then end-coupled to the gain medium. The other approach is to package these laser diodes into pigtailed bars or stacks, which are then end-coupled into the gain medium through a fiber bundle.

Coupling of fibers to pumps

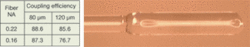

Efficiently coupling light from the pump laser to the pigtail would allow fewer pumps to deliver the same amount of power. The light from lasers with active areas of 1 × 80 to 1 × 120 µm into a multimode fiber with a 100-µm core is typically coupled to a fiber using a wedge polished lens.

Higher brightness in the pigtail would allow a higher density of fibers to be end-coupled to the gain medium. Because the brightness is inversely proportional to the cross-sectional area and the square of the fiber NA, a lower fiber NA would yield a higher-brightness pigtail.

Efficiently coupling pump light to a lower-NA fiber (to increase brightness) would involve more-sophisticated lenses. Coupling efficiencies can be obtained by using lensed fibers for low-NA fiber or with lasers having wider active areas (see Fig. 3).

The reliability of fiber lasers depends on several components within the fiber laser. Regarding the gain fiber, a conversion efficiency of about 70% in the gain medium implies that 30% of the pump power is converted to heat, which is dissipated through the surface of the fiber. When air-cooled, the temperatures at the surface can reach more than 100°C. At such surface temperatures, a polymer cladding is likely to age over time and deteriorate during continuous operation. A fiber in which the second cladding is glass or air holes in glass is likely to be more reliable.

Reliability also depends on ensuring that there is a minimum of free-space optics in the system. Use of an all-glass fiber bundle or a single-polarization fiber that can be spliced to the gain fiber can boost reliability. Sometimes, a fiber bundle is tapered to enable more fibers to be coupled to the inner cladding. Tapering causes a loss in light-a possible source of heat in the system. Even a 10% loss at this point can produce 100 W, all focused in a small volume. Again, an all-glass construction for fiber bundles can mitigate these risks.

Progress at Corning

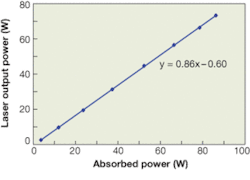

In 2002, Corning entered into an agreement with DARPA (the Defense Advanced Research Projects Agency) to provide a scalable high-power fiber laser. The objective of the program was to deliver linearly polarized output from the laser oscillator. This was achieved through the use of a low-index glass to create a novel all-glass, elliptical-core, hole-assisted, Yb-doped double-clad fiber with an NA of 0.32. Similar short lengths of fiber without any Yb doping demonstrated a polarization extinction of 30 dB. The laser fiber was pumped at each end using a fiber-coupled diode system through the use of high-NA lenses and a set of 980‑nm-transmitting/dichroic mirrors. The pump power was scaled up using an all-glass fiber bundle. The laser operated at 1060 nm with a maximum power output of 104 W, as measured from one end of the laser fiber, for 210 W of coupled pump power. The polarization-extinction ratio was 17 dB. The slope efficiency and laser threshold were 52% and 13 W, respectively,1 for output from a double-clad, single-polarization fiber, and more than 85% for an unpolarized double-clad, single-mode fiber (see Fig. 4).

In addition, Corning has developed gallium arsenide/indium gallium arsenide broad-area pump lasers. For 2-µm-long devices with 120-µm apertures, output powers of 15 W were measured at 16 A of pump current, with a maximum wall-plug efficiency of 65%.2 Typical pumps today are multimode with 2- to 4-W output power, requiring many pumps for high-power applications. Use of the Corning-developed higher-power pumps in the future will allow the number of pumps required to be reduced by a factor of four to seven.❑

REFERENCES

1. D. T. Walton et al., Invited Paper 5709-49, Photonics West 2005.

2. V. Bhagavatula et al., Invited Paper, Photonics West 2004.

Naga Shashidhar and Donnell T. Walton