Microstructured fibers carve themselves specialized niches

Hollow-core photonic-bandgap fibers and solid-core photonic-crystal fibers can be engineered to have properties that are unavailable in conventional fibers.

Research on microstructured optical fibers is making a subtle but important transition from the basic exploration of their properties to more directed development. Enough has been learned about the interactions between guided light and the complex structures inside the fiber for developers to design fibers for specific applications. Examples of applications for solid-core fibers include compact, highly nonlinear cores for novel optical devices, or fibers with large mode-field diameter. Hollow-core fibers can be designed for low nonlinearity, high-power transmission, or to have strong interactions with gases confined in the core. Both types can be designed to have dispersion properties not available in other fibers.

Fabrication techniques also continue to improve. In a milestone demonstration reported last March at the Optical Fiber Communications conference (OFC; Anaheim, CA), Kenji Kurokawa and colleagues from NTT Access Network Service Systems Laboratories (Tsukuba, Japan) reported making a 100-km length of solid-core fiber. Continued refinements in fabrication are also improving properties of microstructured fibers. It’s unclear when they might find practical use in signal transmission, but real-world applications in specialized niches appear possible.

Solid-core and hollow-core fibers

Microstructured fibers fall into two main categories, depending on whether the light-guiding core is solid or hollow. Although the two evolved from the same fundamental ideas, they differ in both light guidance and behavior.

Solid-core fibers are often called photonic-crystal (PC) fibers. They evolved from the concept of a photonic crystal, in which internal defects control light propagation. The cladding of a PC fiber is made by fusing together long thin tubes, leaving an array of holes running along the length of the fiber. One or more solid rods are placed at the center of the assembly to form the light-guiding core, which is considered a “defect” because its optical properties differ from the surrounding cladding. The holes in the cladding layer give it a lower effective refractive index than the solid core, so light guidance can be viewed as based on the same concept as solid fibers-a low-index cladding confining light to a lower-index core.

The details differ significantly, however. The interaction of light waves with the internal microstructure makes the refractive index vary much more strongly with wavelength than in solid fibers. These interactions also allow design of solid-core fibers that are “endlessly” single-mode because they lack a single-mode cutoff wavelength-a minimum wavelength below which the fiber begins transmitting a second mode. The variation of refractive index with wavelength gives PC fibers dispersion properties impossible to achieve in conventional solid fibers. The cores can be made asymmetric to create birefringent fibers, or designed small to produce high nonlinearity.

Hollow-core fibers are often called photonic-bandgap fibers, and light guiding in them works differently from conventional or solid-core fibers. The cladding that surrounds the hollow core has an internal microstructure that blocks the propagation of light at a certain range of wavelengths, called a photonic bandgap. The light-guiding effect occurs only in a limited range of wavelengths-about 200 nm wide-near 1550 nm. At other wavelengths, the hollow core is an antiguide, because it is surrounded by material with a higher refractive index.

Guiding light through a hollow core allows transmission of optical power densities much higher than are possible without causing optical damage to a solid fiber. Gases can be put into the core, for sensing or for other applications. Photonic-bandgap confinement makes hollow-core fibers largely immune to bending losses unless the hollow zones are made large. The air normally found in the core contributes little to dispersion, so waveguide dispersion dominates the chromatic dispersion of hollow-core, making it possible to design in otherwise impossible dispersion properties.

100-km-long solid-sore fiber

Solid-core PC fibers so far have achieved the lowest loss. Their combination of large mode-field diameter, low bending loss, dispersion-tailoring opportunities, and endlessly single-mode propagation make them attractive for extremely broadband transmission. However, the short available lengths had made experiments difficult.

Researchers at NTT changed that by drawing 100 km of solid-core fiber from a silica preform 1.2 m long and 4 cm in diameter with 60 holes running along its length. They saw no discontinuities along the 100-km length. Measured attenuation was among the lowest recorded for photonic-crystal fiber-0.3 dB/km at 1550 nm and 0.45 dB/km at 1310 nm. Imperfections accounted for about 0.15 dB/km of that loss. Rayleigh scattering was the lowest yet reported at 0.85 dB/km/µm4. Fabrication of that length of low-loss fiber showed that microstructured fibers can be made in the same lengths as standard single-mode fibers. Transmission tests with 10-Gbit/s soliton pulses demonstrated the fiber “is a promising candidate for a long-distance transmission medium,” Kurokawa concluded.

Another OFC postdeadline paper reported record nonlinearities as high as 1860 W-1km-1 at 1550 nm in solid-core fibers fabricated from lead silicate glass. Julie Leong of the Optoelectronics Research Centre at the University of Southampton (Southampton, England)) said she and her colleagues calculated that nonlinearities approaching 2000 W-1km-1 at 1550 nm were possible in fiber cores just 0.6 to 1 µm in diameter. Their finished fibers had cores as small as 1 µm suspended on three filaments, concentrating optical power to very high intensity in a clean single mode, and enhancing the nonlinearity of the lead-silicate glass (see Fig. 1). Loss at 1550 nm was 2.3 dB/m-higher than the bulk glass. Pumping the highly nonlinear fiber with 200-fs pulses at 1.06 µm, the group generated supercontinuum pulses with bandwidths of 600 to 750 nm.

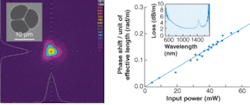

Most solid-core fibers are made by stacking rods and tubes of a single glass to create an air-glass preform which is drawn into a fiber with properties that depend on the refractive-index difference between glass and air. A similar effect is possible by using two glasses with similar thermal expansion but different refractive indexes. This was first demonstrated at Southampton by inserting rods of one glass into tubes of a second glass.1 Later researchers at the University of Bath (Bath, England) stacked rods of two glass compositions to make similar fibers.2 This year at OFC, Xian Feng of Southampton reported making “one-dimensional” microstructures consisting of alternating concentric layers of two glasses with a high-index contrast, instead of the usual two-dimensional array of holes (see Fig. 2). Feng reported “robust single-mode guidance” at both 1047 and 1550 nm, as well as a high effective nonlinearity of 260 W-1km-1 at 1550 nm. (Photonic-bandgap fibers had earlier been made by surrounding hollow cores with cladding consisting of layers of two solids with sharply different refractive index.)

Loss limits for hollow-core fibers

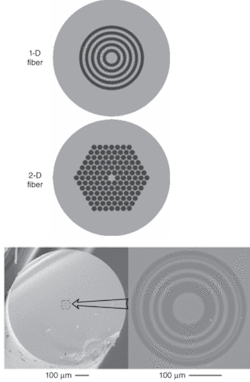

Early developers hoped hollow-core fibers would have low attenuation because they confined light in air rather than in glass. However, demonstrated losses have remained well above those of solid-core fibers. B. J. Mangan and colleagues from Blaze Photonics (Bath, England) reported 1.7 dB/km in an OFC 2004 postdeadline paper, and they later modified their design to reach 1.2 dB/km.3 These low-loss fibers surround the core with a photonic-bandgap cladding that consists of large air holes separated by thin layers of glass (see Fig. 3).

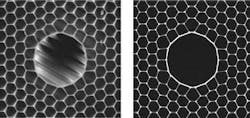

The extra loss arises largely from light coupling into the solid surfaces surrounding the hollow core. This excites surface modes, which in principle are bound within the holey glass cladding, but in practice couple easily to leaky cladding modes, said Theis Peter Hansen of Crystal Fibre (Birkerød, Denmark) at OFC 2005. The coupling strongly depends on wavelength, as would be expected for a photonic bandgap, so attenuation varies widely.

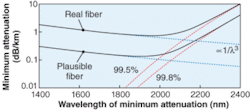

The excitation of surface modes can be suppressed if silica filaments protrude from the cladding into the core.4 However, residual nonuniformities on the nominally glass surface that surrounds the core can scatter light out of the guided mode, causing significant losses. Although careful fabrication can help, a fundamental limit remains, because surface capillary waves formed in molten glass drawn into the fiber are frozen in place when it solidifies, according to a group led by P. John Roberts at Blaze Photonics.3 The result is a residual scattering proportional to the inverse third power of wavelength (λ-3) that imposes a fundamental limit similar to that imposed in solid fibers by Rayleigh scattering, which is proportional to λ-4. Figure 4 plots this effect for the 1.7 dB/km fiber, and extrapolates the effect for a “plausible” fiber with a design refined to decrease coupling. Roberts and colleagues conclude that these refinements could reduce the minimum loss near 1900 nm to around 0.2 dB/km-close to the minimum attenuation of solid fibers near 1550 nm.

One complication is that virtually all hollow-core fibers transmit multiple modes. Developers seeking to reduce coupling losses have increased core size. Corning achieved loss of 13 dB/km in 2003 using a fiber in which seven unit cells were removed to open the core.5 Blaze reduced loss to 1.7 dB/km by enlarging the core to 19 unit cells. Opening the core to 37 unit cells might reduce loss further, but would increase problems already posed by the presence of higher-order core modes, bending loss, and wavelengths where surface resonances peak.

Applications and outlook

Although microstructured fibers haven’t lived up to the wildest hope of their developers, they are making plenty of solid progress. The biggest promise in the near term is development of fibers with special properties to fill niche applications. Microstructures give designers new degrees of freedom so they can produce fibers with a broader range of properties than conventional fibers. Important examples include high nonlinearity and special dispersion properties. The highest degrees of nonlinearity have come from combining highly nonlinear materials with highly nonlinear solid-core fiber structures. The dispersion properties of hollow-core fibers are dominated by waveguide dispersion because most of the light propagates in air, making it easier to design-in special dispersion properties. For example, hollow fibers can have large negative (or normal) dispersion at short wavelengths and large positive (or anomalous) dispersion at long wavelengths, making them valuable for applications such as chirped pulse amplification, where they recombine the dispersed and amplified pulse.

With their solid cores, photonic crystals can be used in nonlinear devices and optical amplifiers. Hollow-core fibers can be filled with gases such as acetylene to act as wavelength references, or other gases for use as sensors (see p. 34). Hollow fibers also can carry high-power beams that would cause optical damage in solids. The list could go on indefinitely. ❑

ACKNOWLEDGMENTS

Thanks to Theis Peter Hansen of Crystal Fibre.

REFERENCES

1. X. Feng et al., Optics Express 11, 2225 (Sept. 8,, 2003).

2. F. Luan et al., Optics Letters 29, 2369 (Oct 15, 2004).

3. P. J. Roberts et al., Optics Express 13, 236 (Jan. 10, 2005).

4. James A. West, et al., Optics Express 12, 1485 (April 19, 2004).

5. C.M. Smith et al., Nature 424, 657 (2003).