Coherent combination of laser beams sidesteps the usual limits on laser power output, while at the same time maintaining high beam quality. For this reason, new methods of coherent beam combination are worthy of attention. New developments in fiber lasers are also of note; fiber lasers require no alignment of cavity mirrors, can be easily integrated with fiberoptic systems, and have no beam wander when properly coupled into a collimating lens for free-space use. A group of researchers at Brown University (Providence, RI) ventured into both of these high-profile areas and came up with a prize.

The group—which has since moved to Boston University (Boston, MA)—coherently combined the outputs of two erbium (Er) doped fiber lasers in an all-fiberoptic setup, opening the way to reliable fiber-laser sources of very high power. According to researchers Ted Morse and Valerii Kozlov, the technique should work for any type of fiber laser and is ultimately limited in power only by material failure—resulting in a potential optical output of at least 0.5 kW for a single-mode fiber.

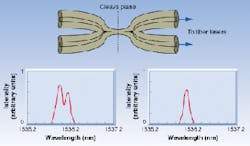

Two 980-nm-pumped Er-fiber lasers were each made 8 m long so that the pump power is nearly all absorbed. Each laser was spliced at one end to its own section of fiber containing a Bragg-grating reflector, with one reflector resonant at 1536.08 nm and the other at 1535.80 nm and with the resonance wavelength of the second reflector temperature-tunable. The other ends of the fiber lasers were spliced via a single-mode-fiber fused taper having a central section with a circular core. Cleaving the central section created a common cavity output mirror for both lasers (see figure).

The two Bragg-grating reflectors have a room-temperature difference in resonance wavelength of 0.28 nm. As one reflector is tuned closer to the other and the optical spectrum of the common output monitored, two peaks are observed until the difference reaches 0.15 nm. At this point, injection-locking occurs and a single peak of twice the intensity of the two original peaks appears, demonstrating coherent beam combination. The core of the fused coupler must have an almost-perfect circular cross section for this effect to occur, say the researchers.

The technique is not limited to the combination of two fibers; N fibers can be combined using an N x N fused-taper coupler with its central coupling area cleaved. The couplings must be low-loss because of heating problems for high-power fiber lasers. Fabricating the lasers using new single-mode fiber designs that have a larger effective area will reduce chances of fiber failure.

Potential uses include micromachining, free-space communication, and surgery at the 1.94-µm water-absorption line. In addition, because modulation of the pump in individual fiber lasers can cause the output to change wavelength, switching applications are possible. Companies such as Polaroid Corp. (Cambridge, MA), Spectra-Physics Lasers (Mountain View, CA), and Lucent Technologies (Murray Hill, NJ) have contributed materials to the Boston University group.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.